3WIKA operating instructions, model DSSA11SA

EN

14543105.01 08/2023 EN/DE

Contents

Contents

1. General information 5

1.1 Abbreviations, definitions . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . . 6

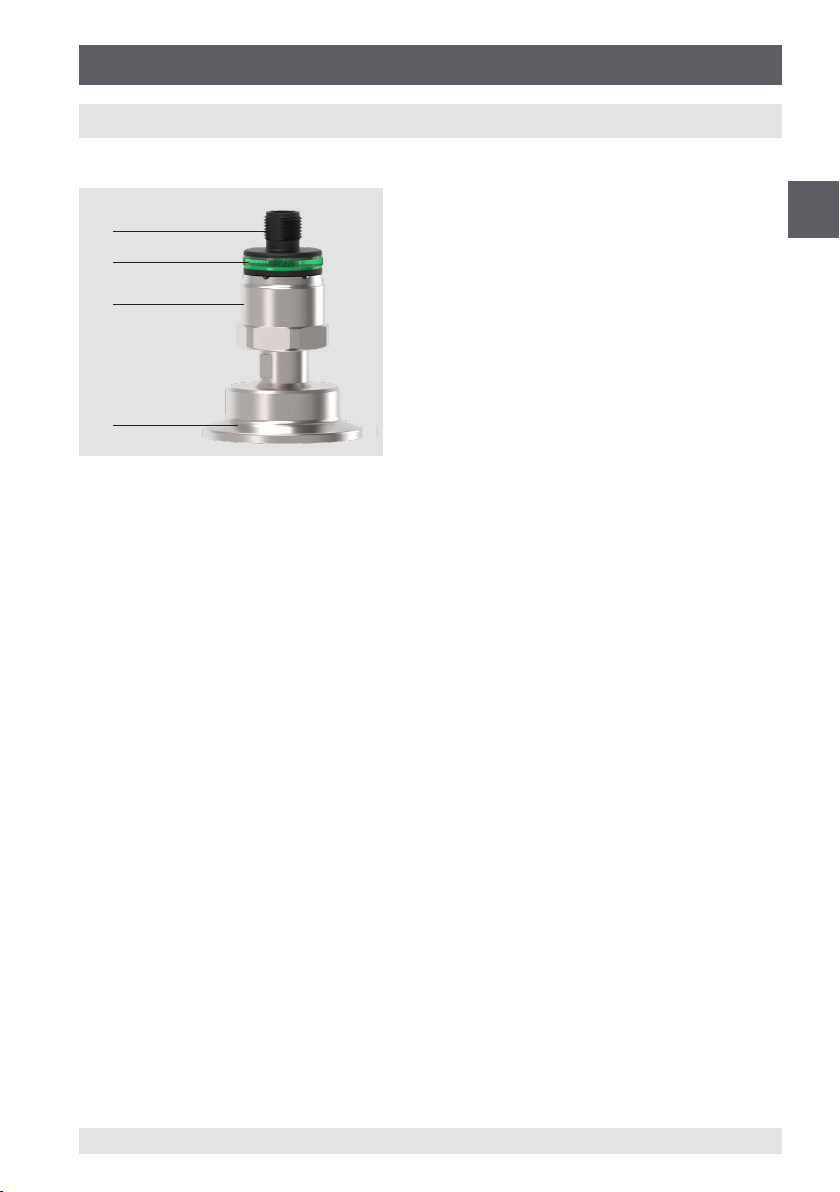

2. Design and function 7

2.1 Overview, diaphragm seal system . . . . . . . . . . . . . . . . . . . 7

2.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Product passport . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Safety 8

3.1 Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Responsibility of the operator . . . . . . . . . . . . . . . . . . . . 10

3.4 Personnel qualification . . . . . . . . . . . . . . . . . . . . . . 11

3.5 Use of accessories and spare parts . . . . . . . . . . . . . . . . . . 11

3.6 Labelling, safety marks . . . . . . . . . . . . . . . . . . . . . . 12

3.7 Compliance with 3-A conformity . . . . . . . . . . . . . . . . . . . 12

3.8 Compliance with EHEDG conformity . . . . . . . . . . . . . . . . . 12

4. Transport, packaging and storage 13

4.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5. Commissioning, operation 14

5.1 General mounting instructions. . . . . . . . . . . . . . . . . . . . 14

5.2 Mounting instructions for diaphragm seal systems with 3-A and EHEDG . . . . . 14

5.3 Requirements for mounting point . . . . . . . . . . . . . . . . . . . 14

5.4 Mechanical mounting. . . . . . . . . . . . . . . . . . . . . . . 15

5.5 Electrical mounting . . . . . . . . . . . . . . . . . . . . . . . 16

5.6 Teach function (if available). . . . . . . . . . . . . . . . . . . . . 16

5.7 Colour codes of the 360° LED status indication . . . . . . . . . . . . . . 17

5.8 Switching functions . . . . . . . . . . . . . . . . . . . . . . . 18

5.9 Damping function (0 ... 65 s) (configurable via IO-Link) . . . . . . . . . . . 19

5.10 Zero point setting . . . . . . . . . . . . . . . . . . . . . . . . 19

5.11 Description of the IO-Link functionality . . . . . . . . . . . . . . . . . 19

5.12 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . 19

6. Faults 20

7. Cleaning, maintenance and recalibration 21

7.1 Exterior cleaning of the diaphragm seal system . . . . . . . . . . . . . . 21

7.2 Cleaning of the diaphragm . . . . . . . . . . . . . . . . . . . . . 22

7.3 Cleaning in place (CIP) cleaning process . . . . . . . . . . . . . . . . 22

7.4 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.5 Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . 22