EN

14028755.03 02/2021 EN/DE/FR/ES

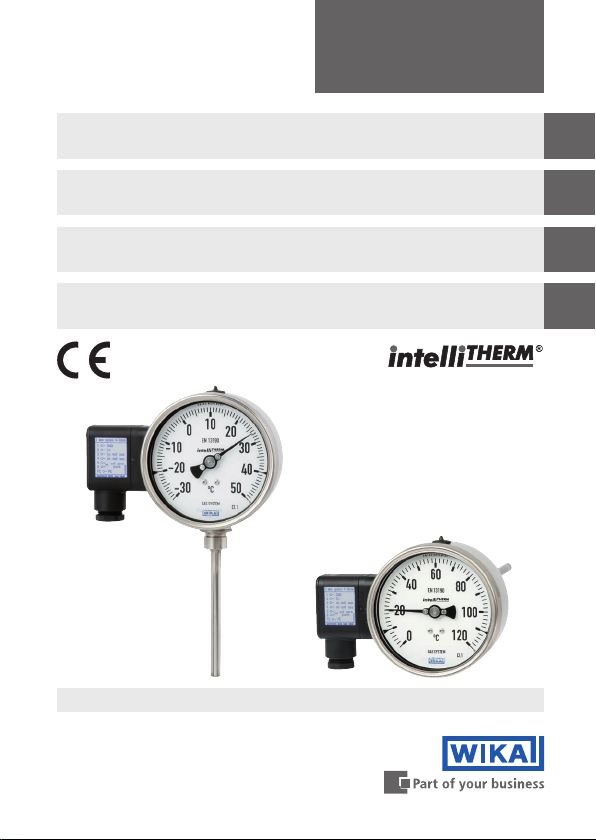

4WIKA operating instructions model TGT73

1. General information

■

The intelliTHERM model TGT73 gas-actuated thermometer

described in these operating instructions has been designed and

manufactured using state-of-the-art technology. All components

are subject to stringent quality and environmental criteria during

production. Our management systems are certied to ISO 9001 and

ISO 14001.

■

These operating instructions contain important information on

handling the instrument.Working safely requires that all safety

instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and

general safety regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept

in the immediate vicinity of the instrument and readily accessible to

skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the

operating instructions, prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused

by using the product contrary to its intended use, non-compliance

with these operating instructions, assignment of insuciently

qualied skilled personnel or unauthorised modications to the

instrument.

■

The general terms and conditions contained in the sales

documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: TV 17.10

1. General information