3

EN

ADPR1X914112.01 09/2020 EN/DE

WIKA operating instructions, model F2812

Contents

Contents

1. General information 4

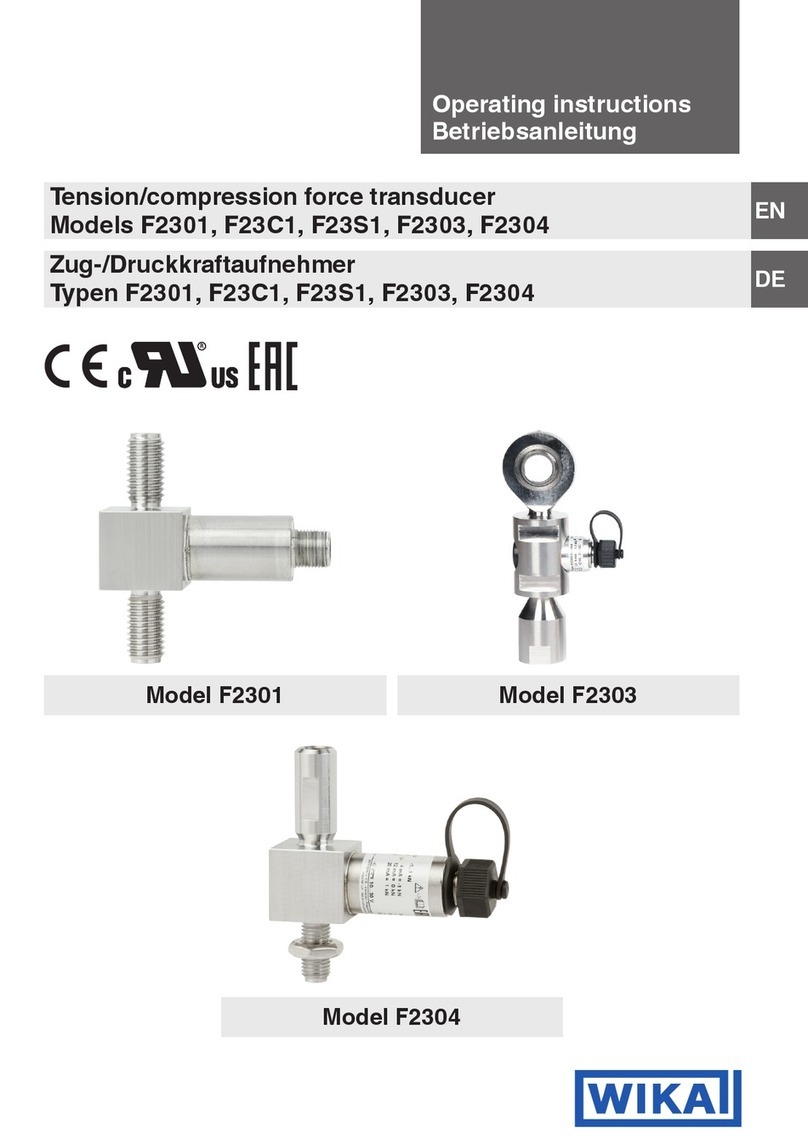

2. Design and function 5

2.1 Overview. . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Description . . . . . . . . . . . . . . . . . . . . . . .6

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . .6

3. Safety 6

3.1 Explanation of symbols . . . . . . . . . . . . . . . . . . .6

3.2 Intended use . . . . . . . . . . . . . . . . . . . . . .7

3.3 Improper use . . . . . . . . . . . . . . . . . . . . . .8

3.4 Responsibility of the operator . . . . . . . . . . . . . . . . .8

3.5 Personnel qualification . . . . . . . . . . . . . . . . . . .9

3.6 Personal protective equipment . . . . . . . . . . . . . . . .9

3.7 Labelling, safety marks . . . . . . . . . . . . . . . . . . 10

4. Transport, packaging and storage 11

4.1 Transport. . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Packaging and storage . . . . . . . . . . . . . . . . . . 11

5. Commissioning, operation 12

5.1 Precautions before commissioning . . . . . . . . . . . . . . 12

5.2 Mounting instructions . . . . . . . . . . . . . . . . . . 12

5.3 Installation of the tension/compression force transducer. . . . . . . 13

5.4 Installation of the tension/compression force transducer with swivel heads 14

5.5 Electrical connection. . . . . . . . . . . . . . . . . . . 15

5.6 Connecting an amplifier. . . . . . . . . . . . . . . . . . 15

5.7 Pin assignment . . . . . . . . . . . . . . . . . . . . 15

6. Faults 16

7. Maintenance and cleaning 17

7.1 Maintenance . . . . . . . . . . . . . . . . . . . . . 17

7.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . 17

7.3 Recalibration . . . . . . . . . . . . . . . . . . . . . 17

8. Dismounting, return and disposal 18

8.1 Dismounting . . . . . . . . . . . . . . . . . . . . . 18

8.2 Return. . . . . . . . . . . . . . . . . . . . . . . . 18

8.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . 18

9. Specifications 19

9.1 Approvals . . . . . . . . . . . . . . . . . . . . . . 19

10. Accessories 20

Annex: EU declaration of conformity 21