2103870.03 GB/D 01/2006

2103870.03 GB/D 01/2006

11WIKA Operating instructions / Betriebsanleitung F-20, F-21

10 WIKA Operating instructions / Betriebsanleitung F-20, F-21

7. Starting, operation GB

7. Starting, operation GB

Functional test

nOpen pressure connections only after the system is without pressure!

nObserve the ambient and working conditions outlined in section 7

Technical data.

nPlease make sure that the pressure transmitter is only used within the overload

threshold limit at all times!

Warning

When touching the pressure transmitter, keep in mind that the surfaces of the

instrument components might get hot during operation.

Caution The output signal must be proportional to the pressure. If not, this might point to

a damage of the diaphragm. In that case refer to chapter 9 Trouble shooting.

When designing your plant, take into account that the stated values (e.g. burst pressure, over

pressure safety) apply depending on the material, thread and sealing element used.

Specifications Model F-20, F-21

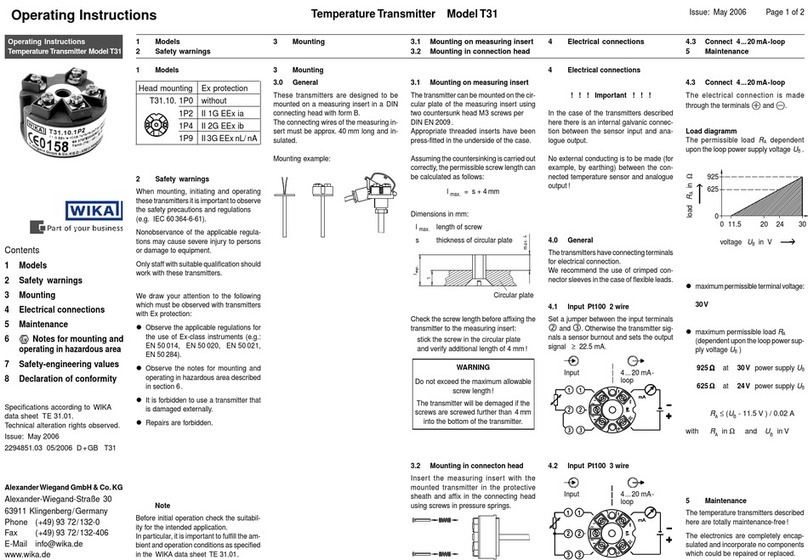

Power supply UBUB in DC V 10 < UB ≤ 30 (11 ... 30 with signal output 4 ... 20 mA,

14 ... 30 with signal output 0 ... 10 V)

Signal output and RA in Ohm 4 ... 20 mA, 2-wire RA ≤ (UB - 11 V) / 0,02 A

maximum load RA0 ... 20 mA, 3-wire RA ≤ (UB - 3 V) / 0,02 A

{0 ... 5 V, 3-wire} RA > 5 000 {0 ... 10 V, 3-wire} RA > 10 000

Test circuit signal / max. load RAOnly for instruments with 4 ... 20 mA signal output;

RA < 15 Ohm with 20mA

Adjustability zero/span %± 10 using potentiometers inside the instrument

Response time (10 ... 90 %) ms ≤ 1

Dielectric strength DC V 500

Accuracy % of span ≤ 0.25 {0.125} 4) (BFSL)

% of span ≤ 0.5 {0.25} 4) 5)

4) Accuracy { } for pressure ranges ≥ 0.25 bar

5) Including non-linearity, hysteresis, non-repeatability, zero point and full scale error

(corresponds to error of measurement per IEC 61298-2).

Adjusted in vertical mounting position with lower pressure connection.

Non-linearity % of span ≤ 0.2 (BFSL) according to IEC 1298-2

1-year stability % of span ≤ 0.2 (at reference conditions)

Permissible temperature of

n Medium 6) *)-30 ... +100 °C {-40 ... +125 °C 7)}-22 ... +212°F {-40 ...+ 257°F 7)}

n Ambience 6) -20 ... + 80 °C {-30 ... +105 °C} -4 ... +176 °F {-22 ... +221°F}

n Storage 6) -40 ... +100 °C -40 ... +212 °F

6) Also complies with EN 50178, Tab. 7, Operation (C) 4K4H, Storage (D) 1K4, Transport (E) 2K3

7) Response time F-20: ≤ 10 ms at medium temperatures below -30 °C for pressure

ranges up to 25 bar

Response time F-21: ≤ 10 ms at medium temperatures below -30 °C (-22 °F)

Specifications Model F-20, F-21

Compensated temperature range 0 ... + 80 °C +32 ... +176 °F

Temperature coefficients within

compensated temp range

n Mean TC of zero % of span / 10 K ≤ 0.2 (< 0.4 for pressure range 0 ... 0.1 and 0 ... 0.16 bar)

n Mean TC of range % of span / 10 K ≤ 0.2

a- conformity 89/336/EEC interference emission and immunity see

EN 61 326, interference emission limit class A and B

97/23/EG Pressure equipment directive (Module H)

Shock resistance g 600 according to IEC 60068-2-27 (mechanical shock)

Vibration resistance g10 according to IEC 60068-2-6 (vibration under resonance)

Wiring protection Protected against reverse polarity and and short circuiting on the

instrument side

Mass kg Approx. 0.35

*) In an oxygen version model F-21 is not available. In an oxygen version model F-20 is only available in gauge pressure ranges

≥ 0.25 bar with media temperatures between -20 … +60 °C / -4 … +140 °F and using stainless steel or Elgiloy® wetted parts.

{ } Items in curved brackets are optional extras for additional price.