2451730.11 01/2015 US/FR

3

US

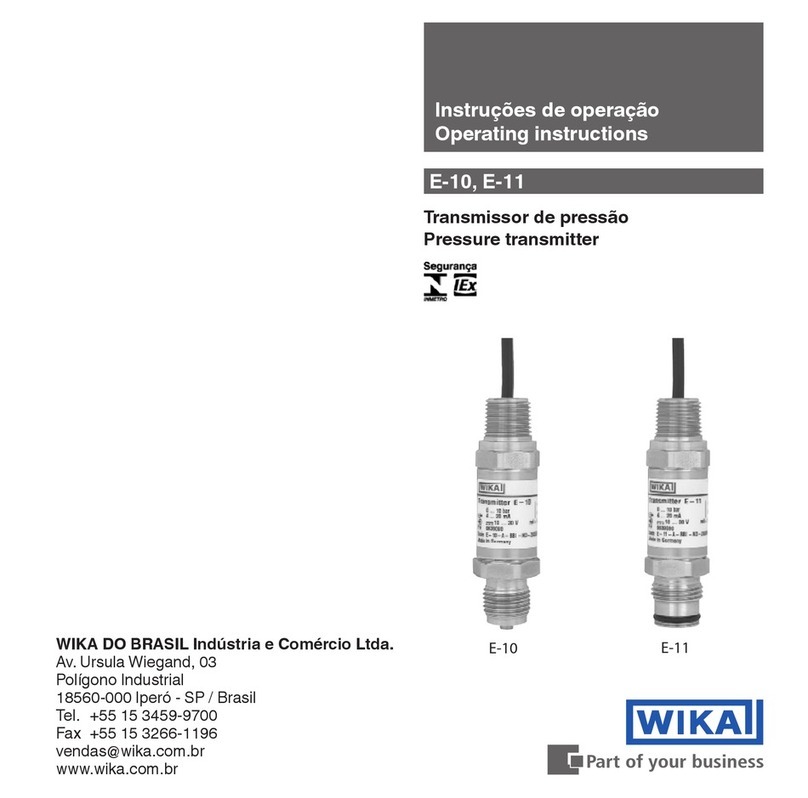

WIKA operating instructions, models E-10, E-11

1. Important details for your information

1. Important details for your information

Read these operating instructions before installing and starting the pressure transmitter. Keep

the operating instructions in a place that is accessible to all users at any time.

The following installation and operating instructions have been compiled by us with great care

but it is not feasible to take all possible applications into consideration.These installation and

operation instructions should meet the needs of most pressure measurement applications.

If questions remain regarding a specific application, you can obtain further information:

■

Via our Internet address www.wika.de / www.wika.com

■

The product data sheet is designated as APE E-10

■

Contact WIKA for additional technical support (770) 513 8200

If the serial number on the case and/or the 2D code on the hexagon gets illegible (e.g. by

me-chanical damage or repainting), the retraceability of the instrument is not possible any more.

WIKA pressure transmitters are carefully designed and manufactured using state-of-the-art

technology. Every component undergoes strict quality and environmental inspection before

assembly and each instrument is fully tested prior to shipment.

Intended use

Use the explosion proof pressure transmitter to transform the pressure into an electrical signal in

hazardous areas.

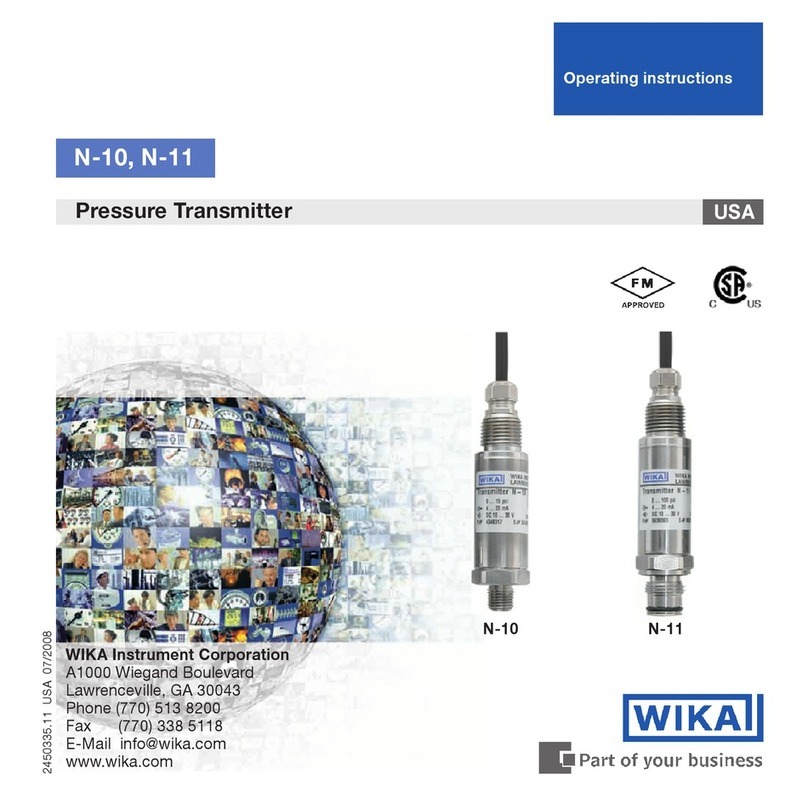

FM and CSA certification

Pressure transmitter for operation in hazardous areas in compliance with the respective certifi-

cate (see Control drawing No. 2323872, section 12).

FM and CSA Approval ratings:

Explosion proof: Class I, Division 1, Groups A, B, C and D

Dust-ignitionproof: Class II, Division 1, Groups E, F, and G; Class III, Division 1