GB

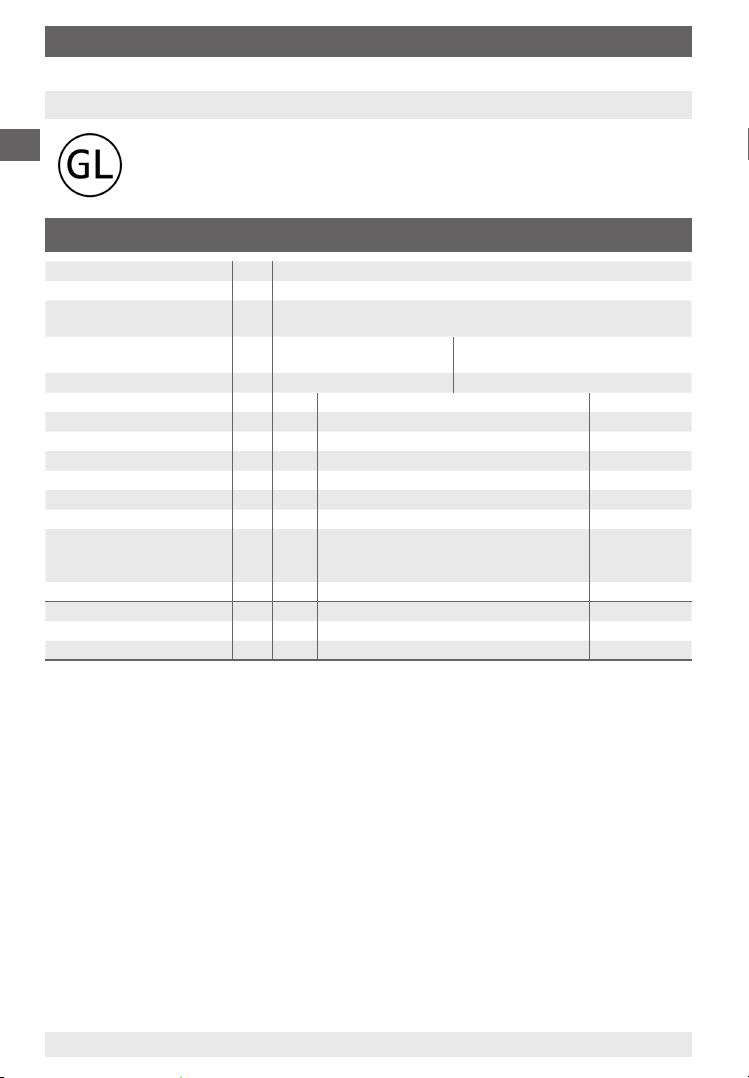

8. Technical data

Technical data DELTA-trans, Model 891.34.2189

Differential measuring range bar 0 ... 0.16 to 0 ... 25

Working pressure (stat.) max. bar 25

Overload value either side max.

bar 25

Pressure connections exposed

to medium

2 x G ¼ female, bottom, in-line, centre distance 26 mm (optional: other

pressure connections male or female or compression fitting with ferrule for

pipe Ø 6, 8 or 10 mm respectively)

Pressure media chamber

exposed to medium

GD-AlSi 12 (Cu) 3.2982, black painted (optional GD-AlSi 12 (Cu) HARD-COAT

surface protection or stainless steel)

Press. element comp. spring stainless steel 1.4310 or FD SiCr EN 10 270-2

Press. element separ. diaphr. FPM/FKM fabric back stay (optional NBR)

Links stainless steel 1.4305, FPM/FKM (optional NBR)

Sealing rings FPM/FKM (optional NBR)

Press. equalising valve

(optional)

stainless steel and FPM/FKM

4-way valve manifold

(optional)

Cu-alloy or stainless steel, 1x Press. equalising valve, 2 x gauge valve,

1 x valve for purging or air bleeding

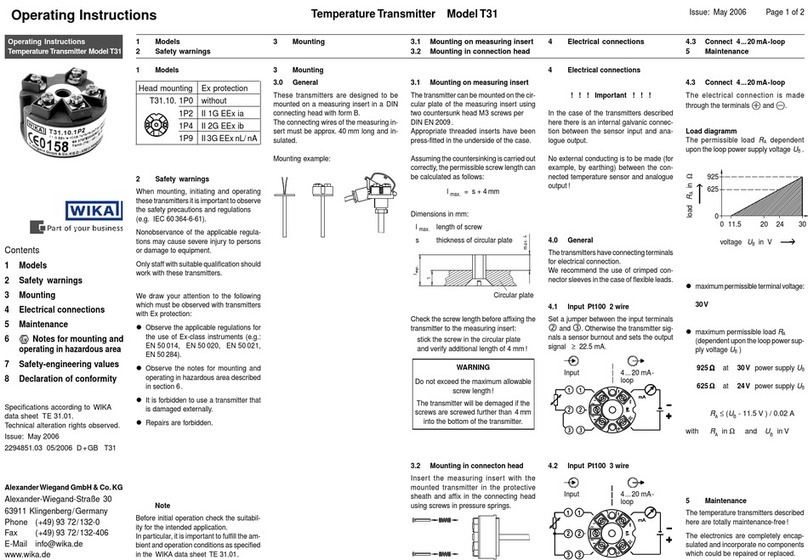

Power supply UBDC V 10 <UB≤30 (optional LCD-display 14 <UB≤30)

Permissible residual ripple ≤0.1 % of span/10 V

Supply voltage effect % ss ≤10

Output signal and permissible

max. load RA

4 … 20 mA, 2-wire system RA≤(UB- 10 V) / 0.02 A with RAin Ohm and UBin Volt

0 … 20 mA, 3-wire system RA≤(UB- 10 V) / 0.02 A with RAin Ohm and UBin Volt

Effect of load % of span ≤0.1

Response time s approx. 1 (optional approx. 50 ms)

Output signal adjustment

Zero point, electrical% of span ± 15

Span, electrical% of span ± 30

Linearity % of span 2.5 (limit point calibration)

(including hysteresis) optional 1.6 (limit point calibration)

Permissible

Medium temperature°C +80 maximum

Ambient temperature°C -10 … +60 (optional LCD-display 0 … 50)

Compensated temp. range °C -10 … +60 (optional LCD-display 0 … 50)

Temperature coefficient in

compensated temp. range

Average TKon zero point≤0.4 % of span/10 K

Average TKon span≤0.4 % of span/10 K

LCD-display (optional)

Voltage loadDC V 3.5

Display3 ½-digit, height 12.7

Ambient temperature°C 0 … 50

Storage temperature°C -10 … +80

Wiring Terminal box (screw terminals up tu 2.5 mm²)

Wiring protection Protected against reverse polarity and overvoltage

EMC (electro-magnetic

compatibility)

Interference emission per EN 50 081 - 1 (March 93) and EN 50 081 - 2 (March 94),

Interference immunity per EN 50 082 - 2 (March 95)

Ingress protection IP 54 (optional IP 65) according EN 60 529 / IEC 529

Weight kg approx. 1.3

2279453 08/2009 GB/D/F

WIKA Operating Instructions Differential Pressure Transmitter DELTA-trans 9

8. Technical data