Wilding Wallbeds KING SIZE User manual

Other Wilding Wallbeds Indoor Furnishing manuals

Wilding Wallbeds

Wilding Wallbeds Studio Series User manual

Wilding Wallbeds

Wilding Wallbeds Remington Queen User manual

Wilding Wallbeds

Wilding Wallbeds PARK CITY User manual

Wilding Wallbeds

Wilding Wallbeds Brittany Installation and operation manual

Wilding Wallbeds

Wilding Wallbeds Side Mount User manual

Wilding Wallbeds

Wilding Wallbeds C90 User manual

Wilding Wallbeds

Wilding Wallbeds King Size with Storage Headboard User manual

Wilding Wallbeds

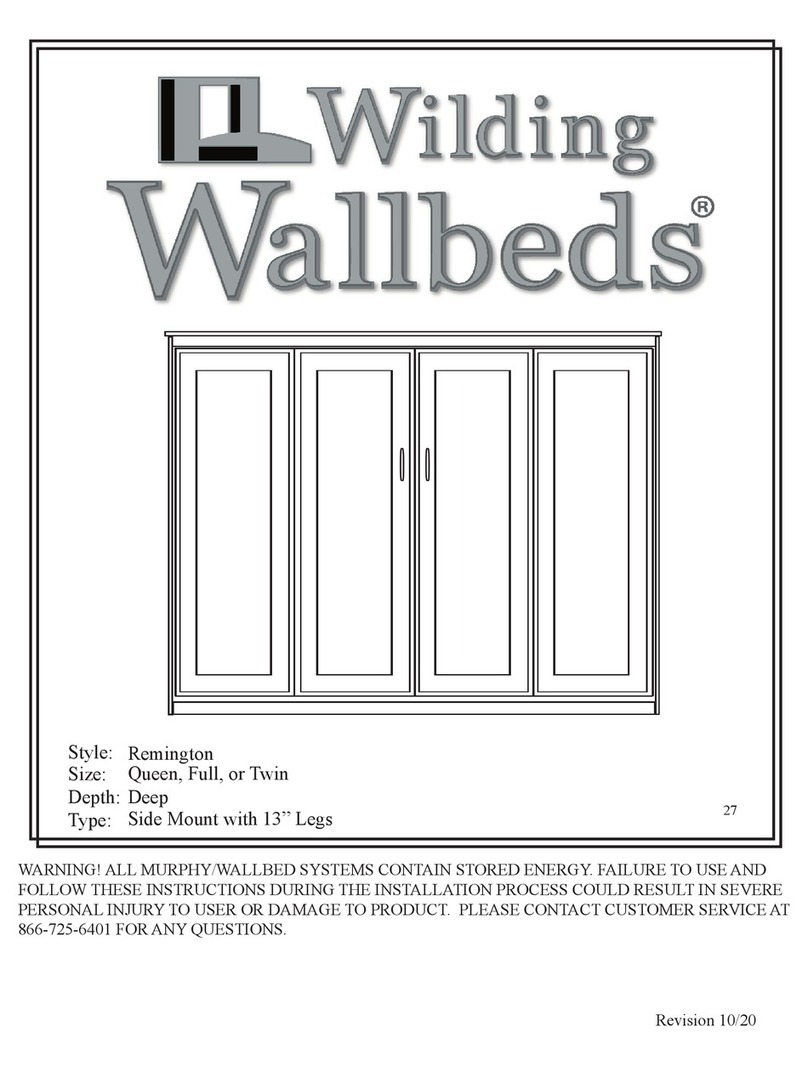

Wilding Wallbeds Remington User manual

Wilding Wallbeds

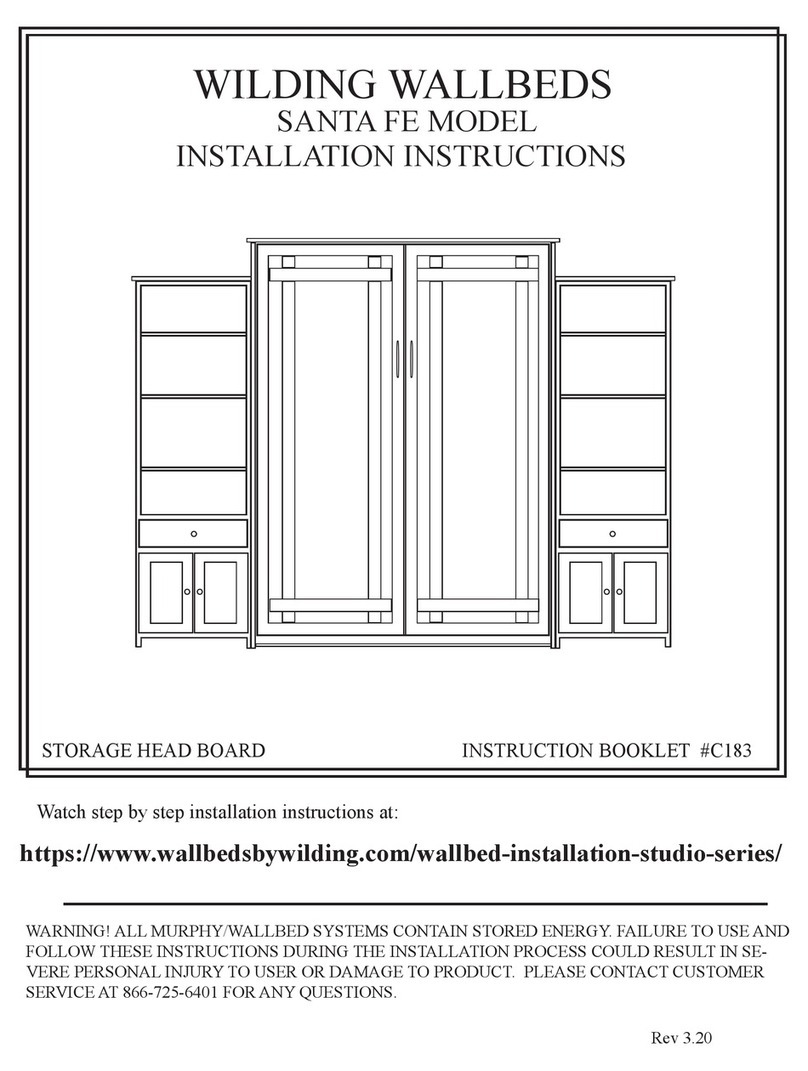

Wilding Wallbeds SANTA FE User manual

Wilding Wallbeds

Wilding Wallbeds PARK CITY User manual

Wilding Wallbeds

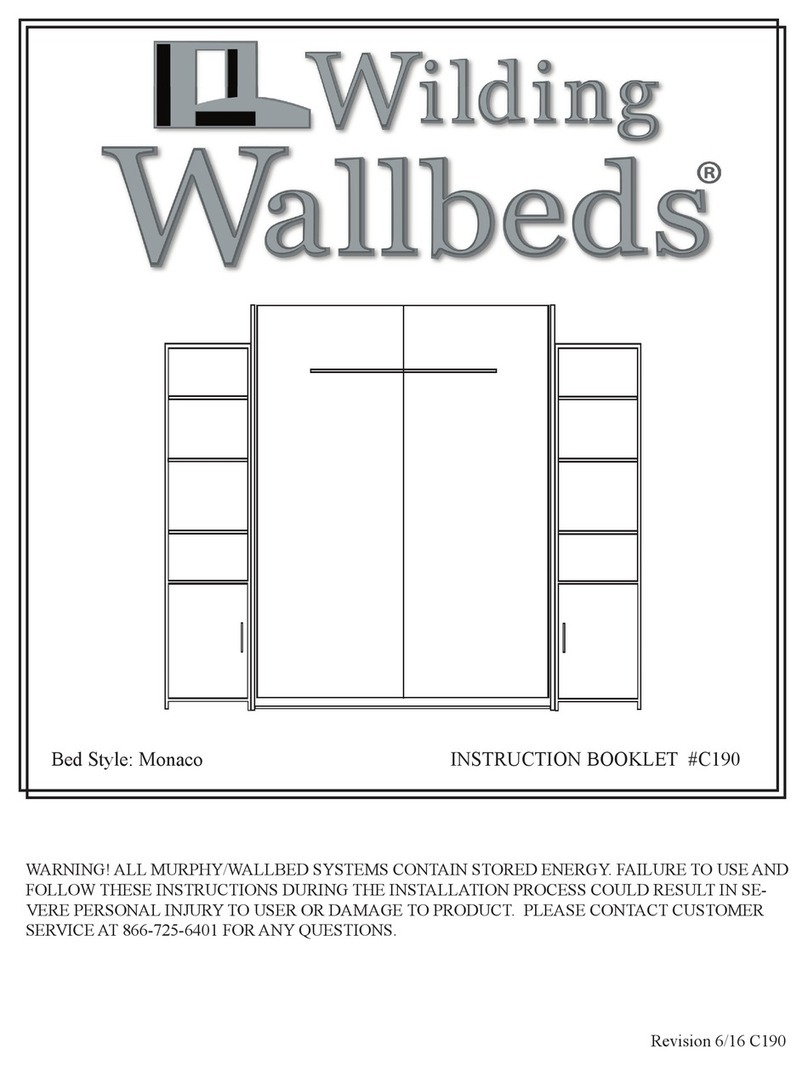

Wilding Wallbeds Monaco User manual

Wilding Wallbeds

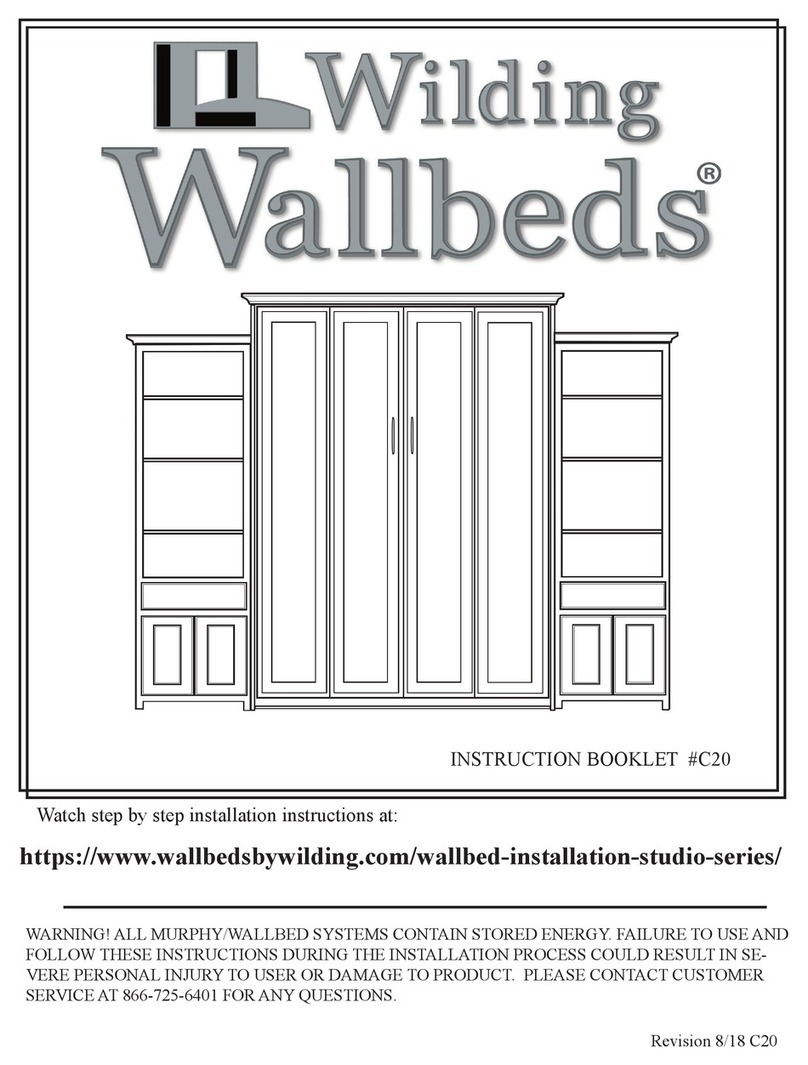

Wilding Wallbeds Studio Series User manual

Wilding Wallbeds

Wilding Wallbeds Brittany User manual

Wilding Wallbeds

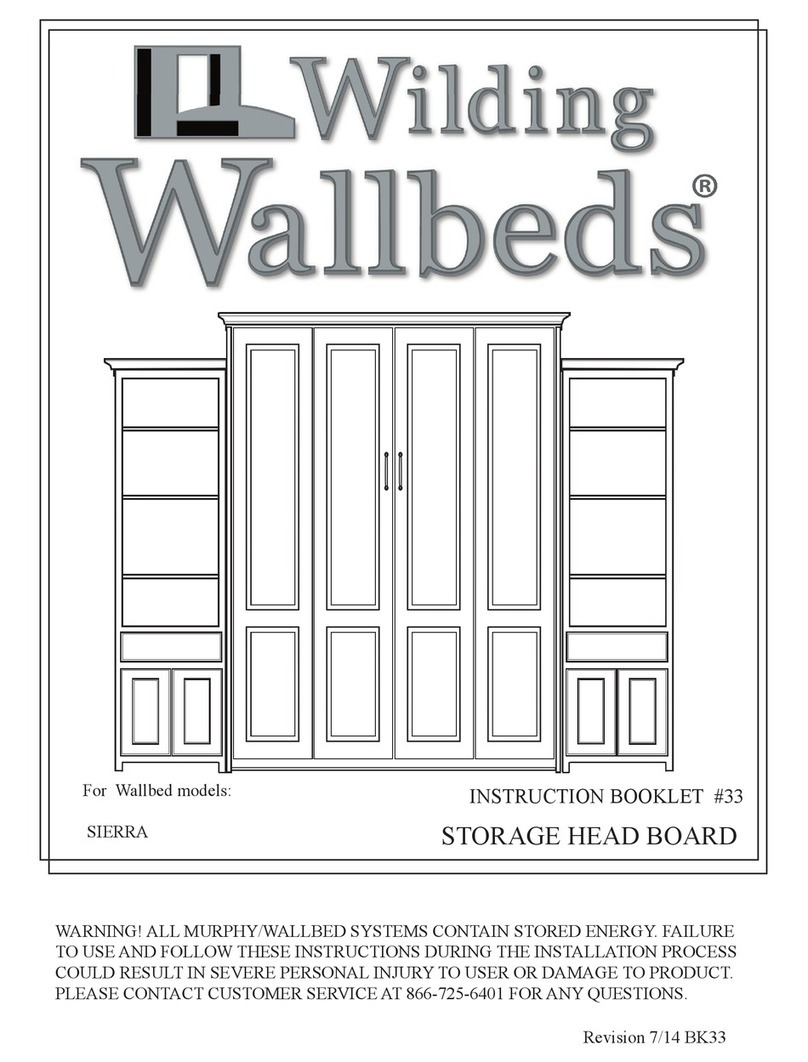

Wilding Wallbeds Sierra User manual

Wilding Wallbeds

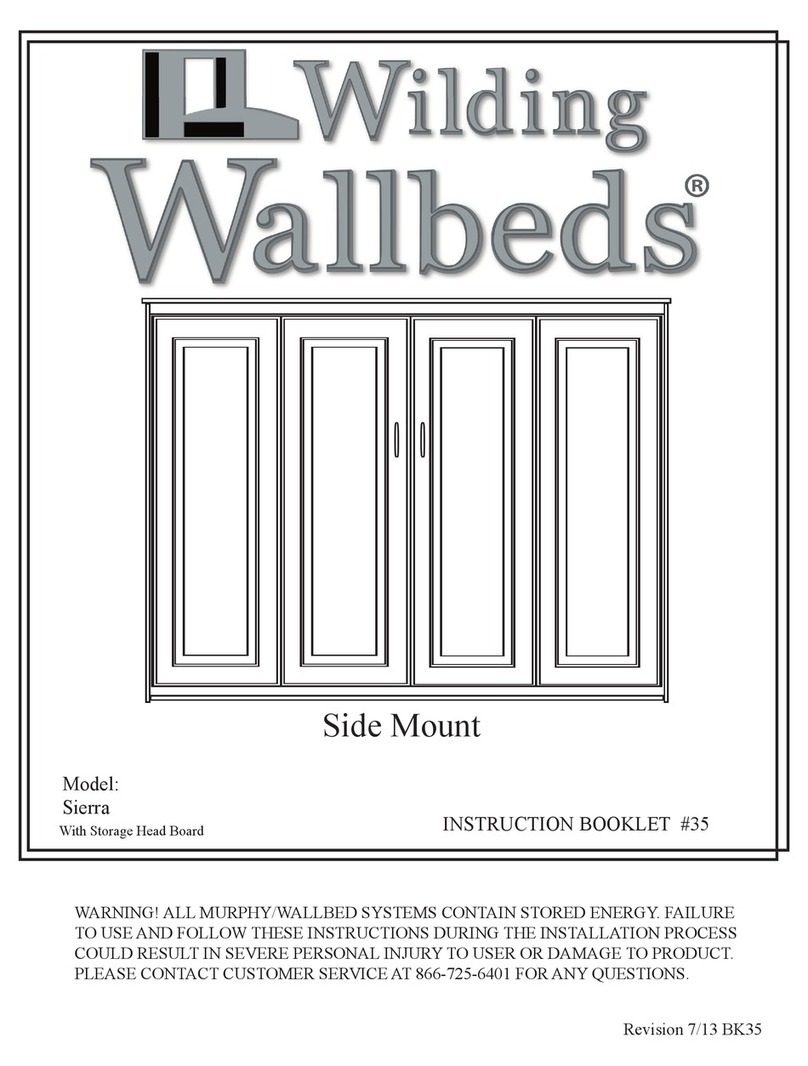

Wilding Wallbeds Sierra User manual

Wilding Wallbeds

Wilding Wallbeds Brittany User manual

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual