Thank you for purchasing this quality product. !"#$%

" &$'%

$ "$

Keep these operation instructions safe.

(

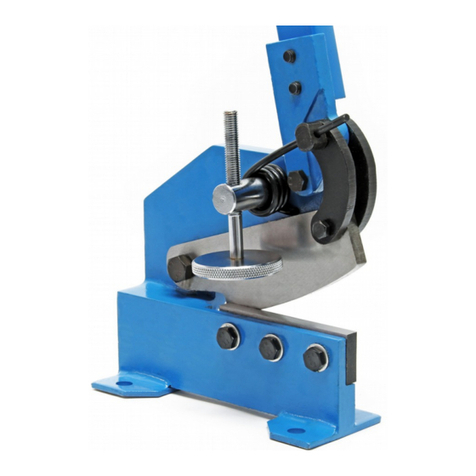

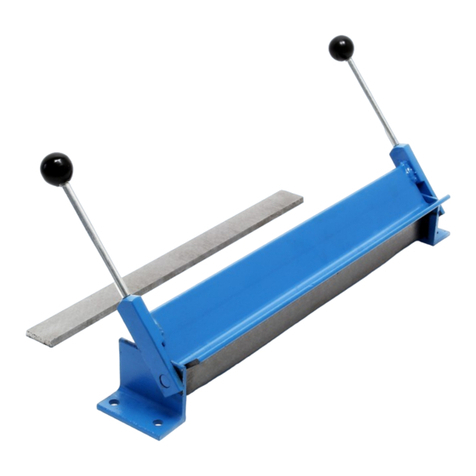

The beading machine is operated by hand and forms sheets up to a thickness of 0.8=mm. The

machine is made of cast iron and steel, which ensures minimal deflection of the workpiece

during forming.

Six die sets included can be used to perform the following operations: large and small turning,

beading, flanging and milling.

)$

Read all safety warnings and instructions before using the device. Failure to comply with the

safety instructions can lead to property damage and injuries.

Keep your work area tidy and ensure that there is adequate lighting. Untidy and poorly lit

workplaces increase the risk of injury.

Pay attention to your working conditions. Do not use the device in a damp or wet environment.

Do not expose the device to rain.

Keep children away from your work area. Do not allow them to operate the beading machine.

Store unused devices and accessories. When not using the device, store it in a dry place.

Lock it up securely and keep it out of children’s reach.

Do not use the beading machine forcibly. It works better and safer when used in the perform-

ance range for which it is intended.

Put on appropriate protective equipment, e.=g. protective goggles and safety gloves.

void loose clothing or jewellery and tie long hair together. Loose clothing, jewellery, or loose

hair can get caught in moving parts and cause injury.

Make sure that you have a secure stance and do not lean too far forward.

Keep your hands and fingers away from moving parts. Risk of injury!

Care for and maintain the device carefully. Keep it clean for better and safer performance.

Keep the handle dry, clean, and free of oil and grease.

Stay alert and focus your full attention on what you are doing. Do not use the device when you

are tired or under the influence of alcohol, drugs or medication.

Check the device for damaged parts before each use. Make sure that it can work safely.

Check the beading machine for incorrectly aligned and blocked moving parts, broken parts or

defective assembly devices, as well as all other circumstances that could impair safe opera-

tion.

If any part of the device is damaged, it should not be used any longer. Damaged parts must

be properly repaired or replaced before using the beading machine again.

© by WilTec Wildanger Technik GmbH Item 62053 Page 3

http://www.WilTec.de

http://www.aoyue.eu 03 2021-1

http://www.teichtip.de