3

INS TALL AT IONR E QUIREME N T S

WHAT TO DO IF YOUSMELLGAS:

Do not try to lightany appliance.

Do not touch any electrical switch.

Do not use any phone in your

building.

Immediately callyourgassupplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

If you cannot reach yourgas

supplier, call the fire department.

W O L F G A S COO K T O P S

Installation to be carried out only

by an authorised person.

Do not modify this appliance.

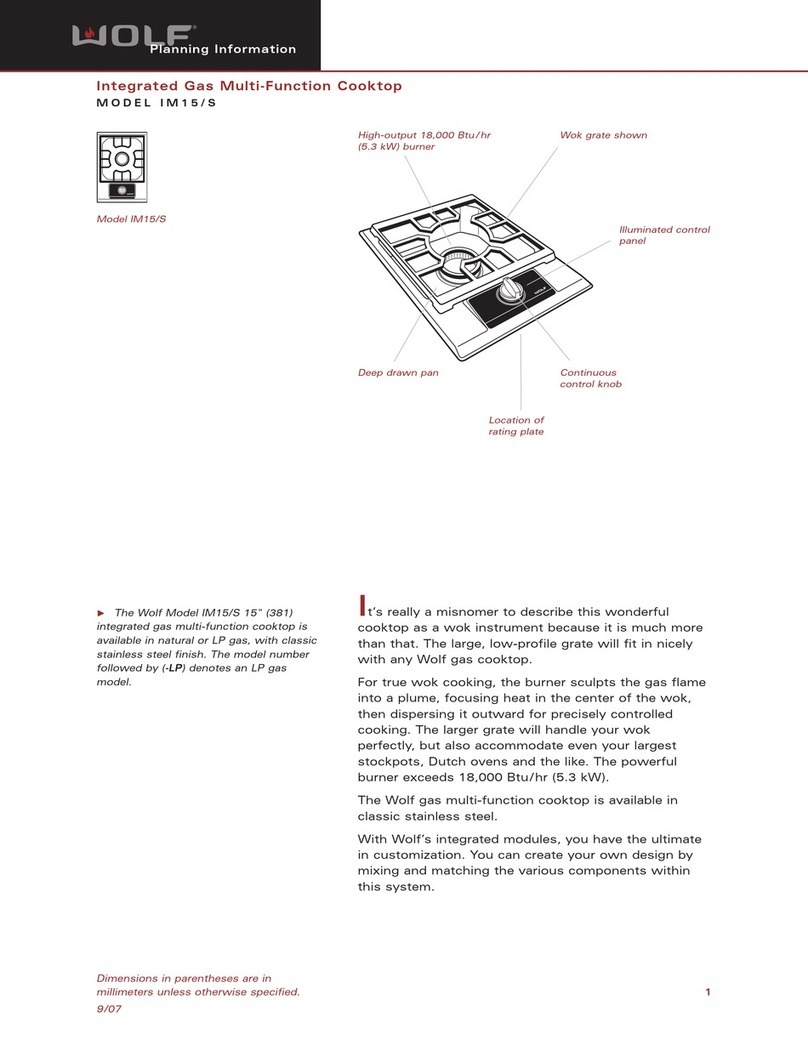

A ventilationhood is recom-

mended for use with the Wolf gas

multi-function cooktop.

Do not store or use gasoline or

otherflammablevaporsand

liquids in the vicinity of this or any

otherappliance.

The use ofagas cookingappliance

results in the production of heat

and moisture in the room in which

it is installed. Ensure that the

kitchen is well ventilated; keep

natural ventilationholesopen or

install a mechanical ventilation

device (mechanical extractor

hood).

Prolonged intensive use of the

appliance may for additional venti-

lation, for example opening of a

window, or more effective ventila-

tion, for example increasing the

level of mechanical ventilation

where present.

This appliance shallbeinstalled

in accordancewiththeregula-

tions in force and only used in a

well ventilated space. Read the

instructionsbeforeinstalling or

using this appliance.

Installer:Pleaseread the entire

InstallationInstructionsprior to

installation. Savethese instructions

for the local inspector’s reference,

then leave them with the home-

owner.

Homeowner:Please read andkeep

theseinstructions for future refer-

enceand be sure to read the entire

Use&Care Informationprior to use.

IMPORTANTNOTE:

COOKTOPS installation manual:Intl Gas Cooktops Install 31/3/10 2:24 PM Page 3

Statutory requirements: This appliance shall

be installed in accordance with the manufacturer’s

installation instructions, local gas fitting

regulations and authority, municipal building codes,

electrical wiring regulations, and AS/NZ5601 the

Australian Standard for gas installations. Refer

also to AS/NZ5601 for gas pipe sizing tables.

Not suitable for use in marine craft, caravans or mobile

homes, unless each burner is fitted with a flame

safeguard.