3

TABLE OF CONTENTS

SUBJECT PAGE

Background, Technical Support, and Trademark Usage...........................................................2

Table of contents .................................................................................................................3

A-1-OGU conversion kit installation instructions ....................................................................4

Installing Diamond sharpening wheel ................................................................................4

Installing OOKAMI GOLD® polishing wheel .................................................................4

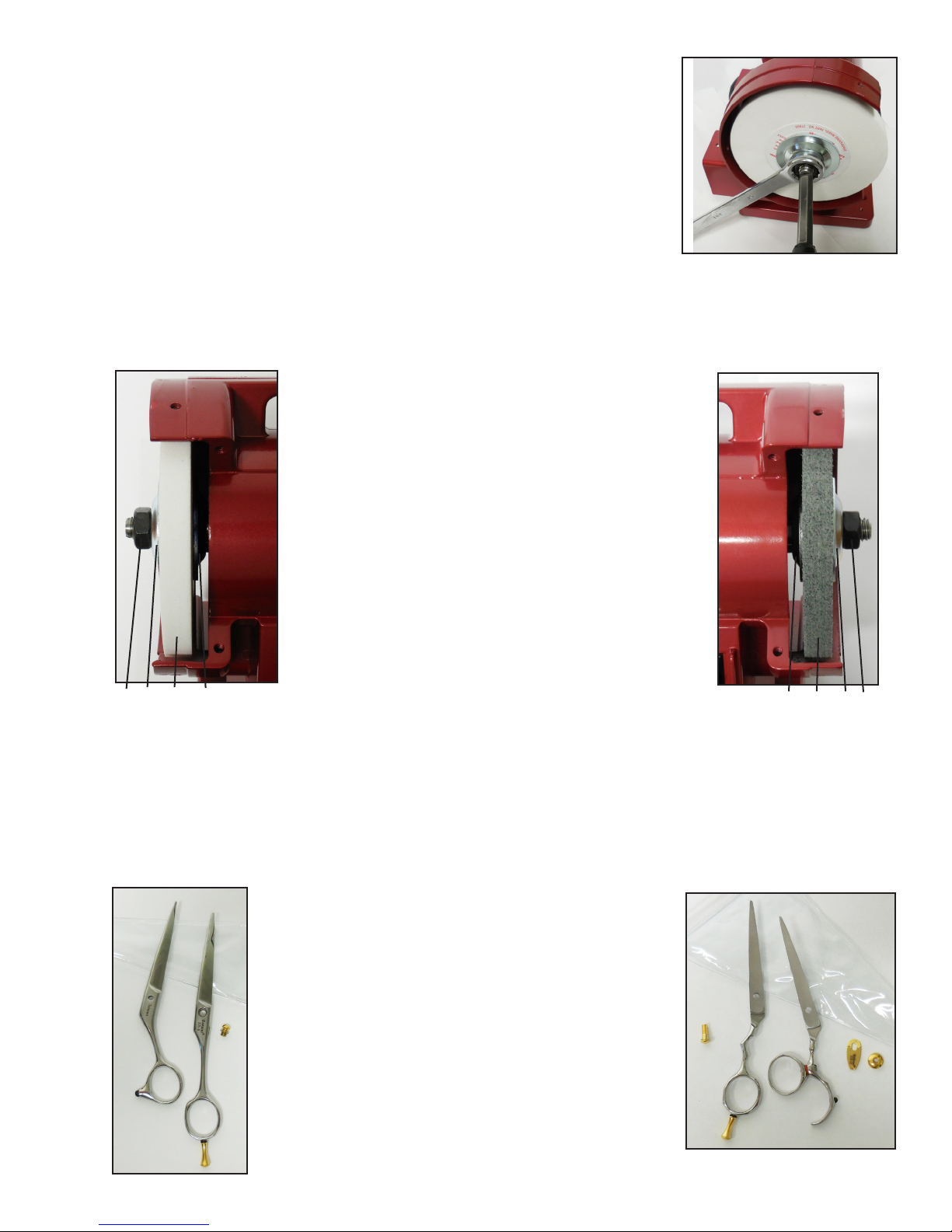

Part names for Scissors and Shears Sharpener .........................................................................5

Set up and safety .......................................................................................................................5

Machine maintenance ...............................................................................................................6

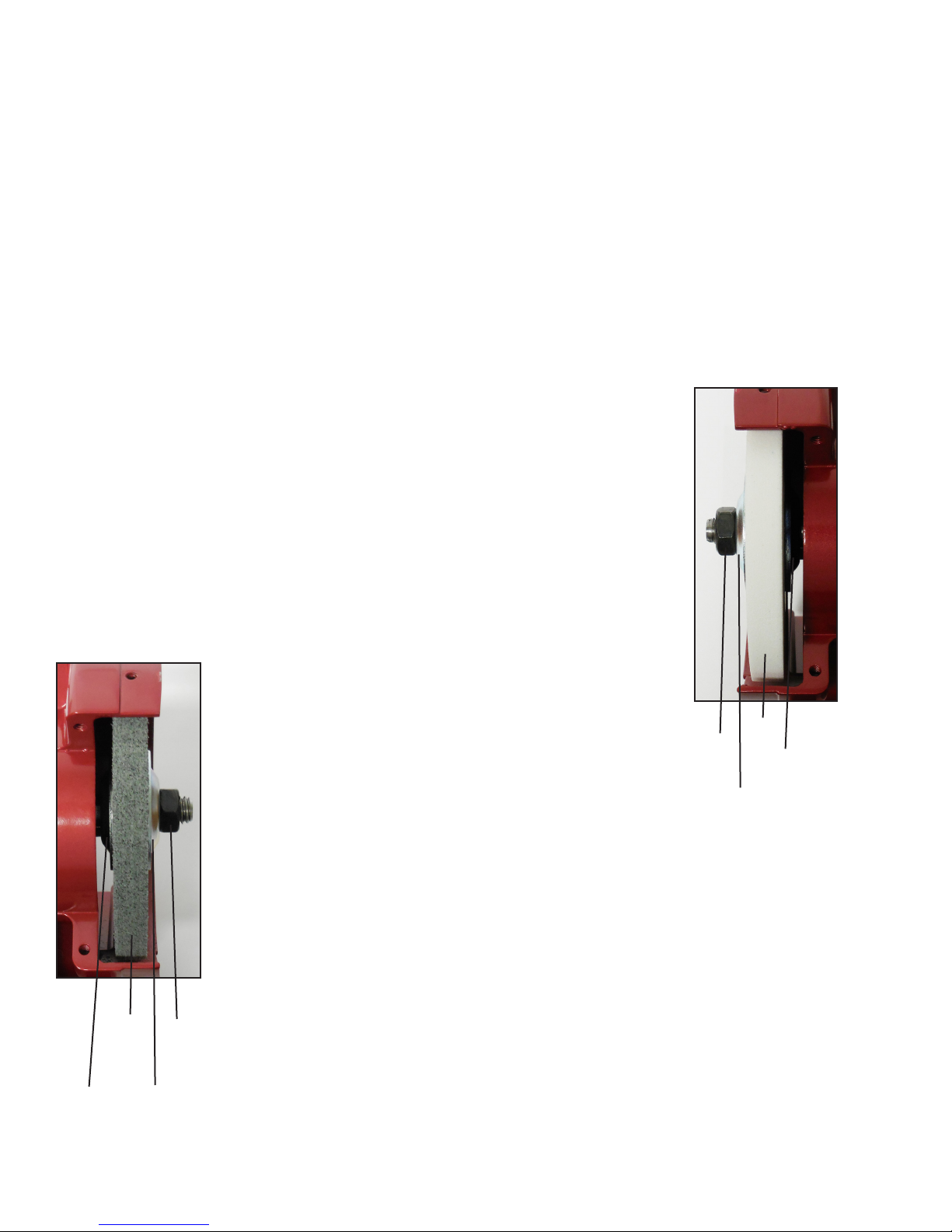

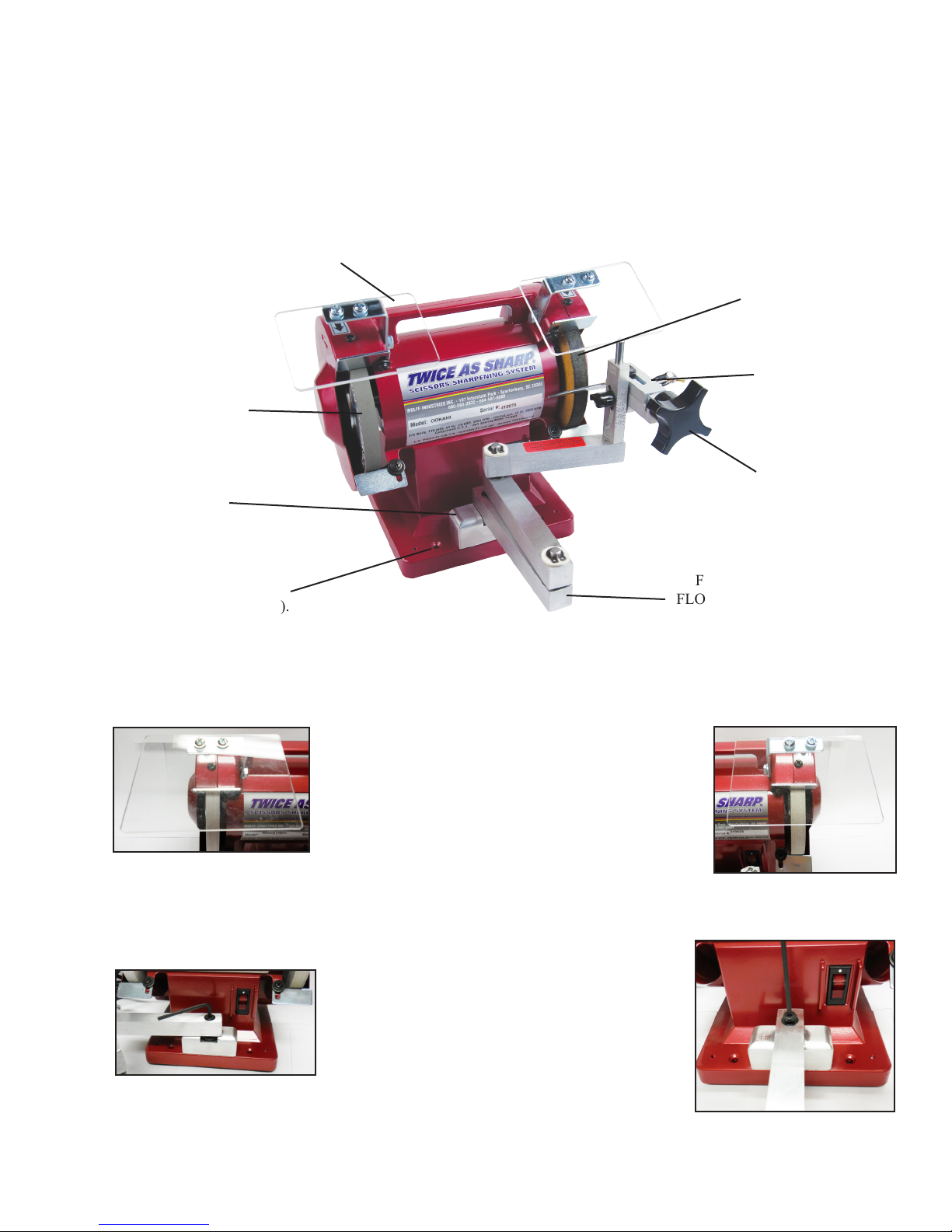

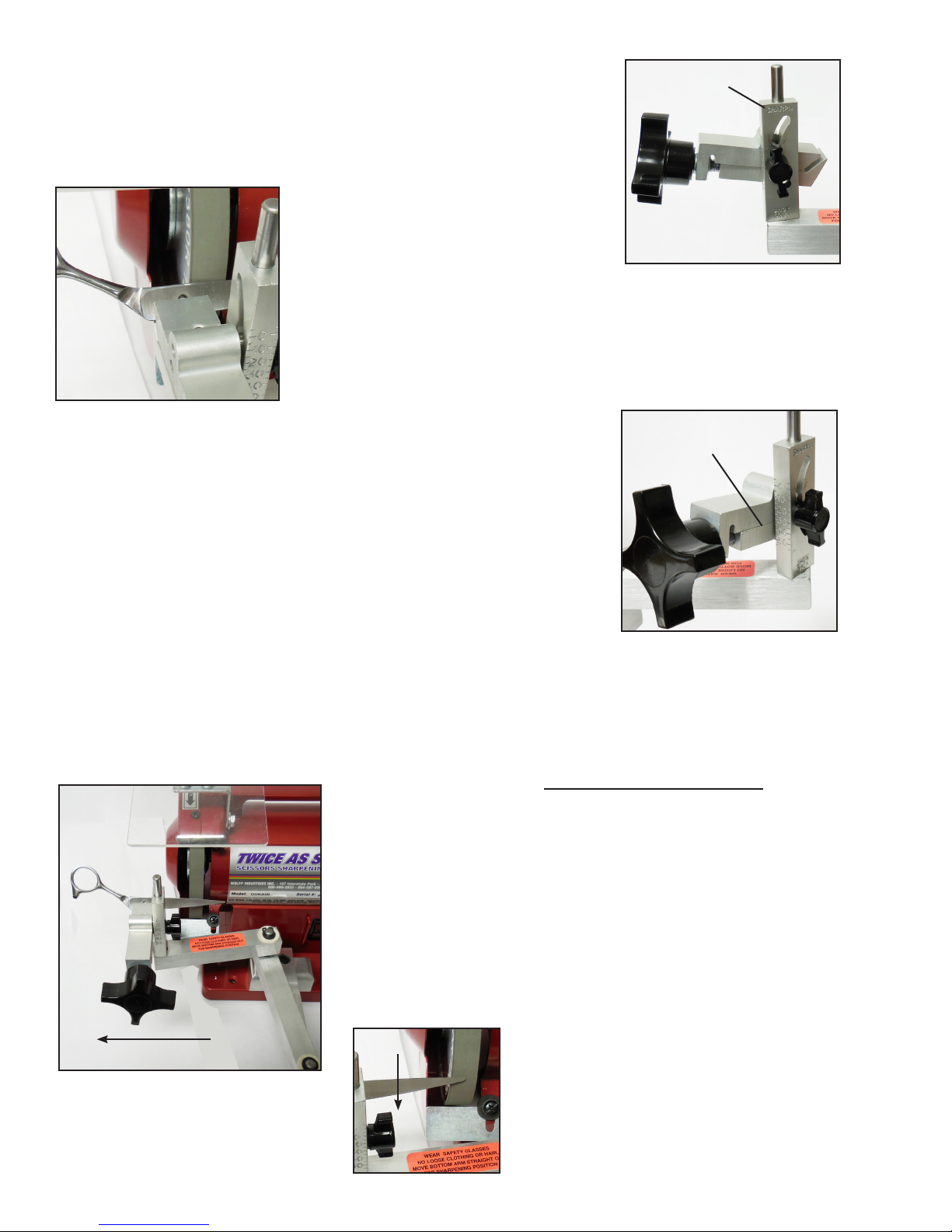

How to change the wheels ........................................................................................................7

Steps to sharpen OOKAMI GOLD® style convex shears

Step 1: Taking shears apart .................................................................................................7

Step 2: Installing the clamp.................................................................................................8

Step 3: Clamping scissors ...................................................................................................8

Step 4: Setting cutting angle ...............................................................................................8

Step 5: Sharpening each blade on the diamond wheel........................................................8

Step 6: Deburring ................................................................................................................9

Step 7: Polishing the blades ................................................................................................9

Step 8: Assembling the shears............................................................................................12

Step 9: Polishing the shears................................................................................................13

Step 10: Testing the shears...................................................................................................13

Step 11: Checking the set of the blades ...............................................................................14

Step 12: Balancing the shears ..............................................................................................15

Step 13: Sizing the blades ....................................................................................................15

Step 14: Matching the tips....................................................................................................16

Step 15: Cleaning and lubricating the shears .......................................................................16

How much to charge ................................................................................................................17

Special instructions for left handed shears...............................................................................17

Corrugating instructions...........................................................................................................18

Frequently asked questions......................................................................................................19

Convexing a bevel edge shear..................................................................................................21

Converting from 110 volt to 220 volt, with existing switch ....................................................22

Converting from 110 volt to 220 volt, with new switch ..........................................................23

Scissors and shears terms dictionary........................................................................................24

Parts included with the OOKAMI GOLD®sharpening system ..............................................29

OOKAMI GOLD®special tools..............................................................................................30

Parts list for clamps..................................................................................................................31

Parts list for OOKAMI GOLD®scissors sharpener................................................................32

Limited Warranty, Disclaimer, and Guarantee.........................................................................34