8

SliderBuckle

Feeder

Arms installation

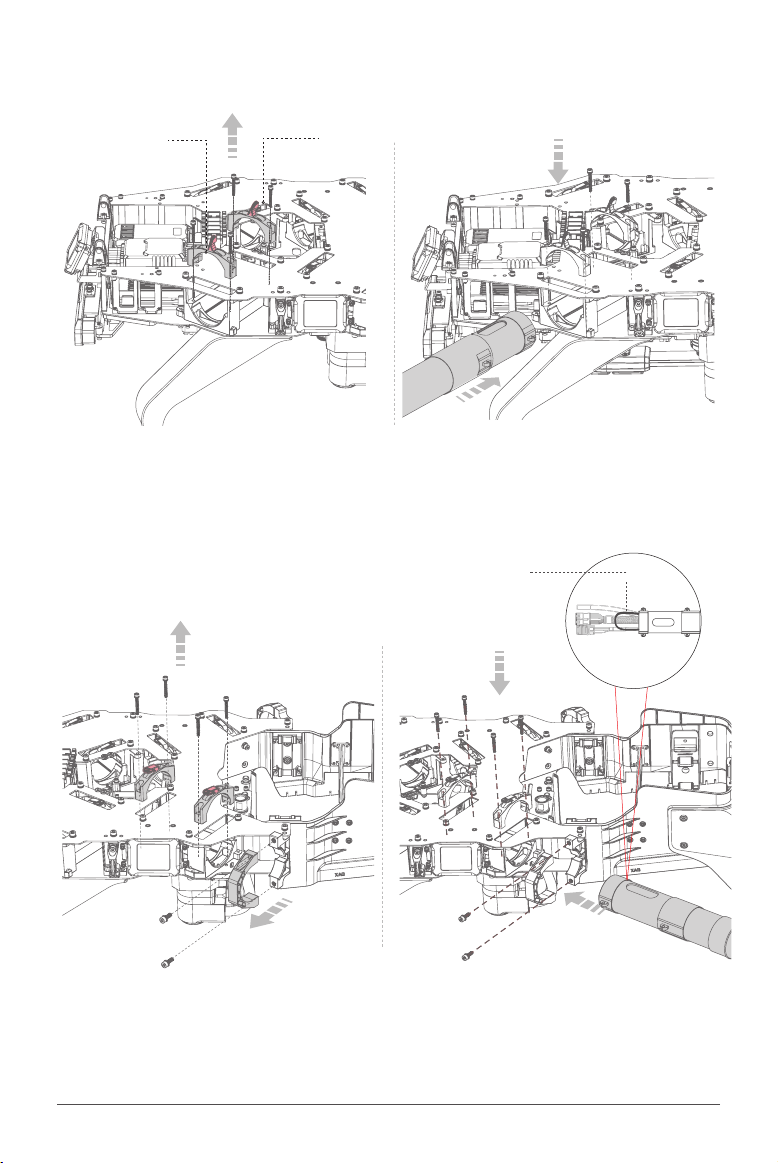

4. Dismantle the fixed sliders of No.1 and

No.2 arm

Dismantle screws (4 screws on 2 sliders) on

limiting stopper of No.2 arm top sliders; and,

then pull out the sliders.

5. Install No.1 and No.2 arm

Insert the No.2 short arm from designated

position of airframe plate, and then install the

top slider back to its original position to complete

assembling of No.2 arm. (The dismantling/

installation of No.1 arm is the same as that of

No.2 arm)

6. Dismantle the fixed slider of No.3 and

No.4 arm

Dismantle screws (4 screws on 2 sliders) on

limiting stopper of No.3 arm top sliders; and,

then pull out the sliders and remove carbon

framed fasteners (2 screws on 1 fastener) of side

arms.

7. Install No.3 and No.4 arm

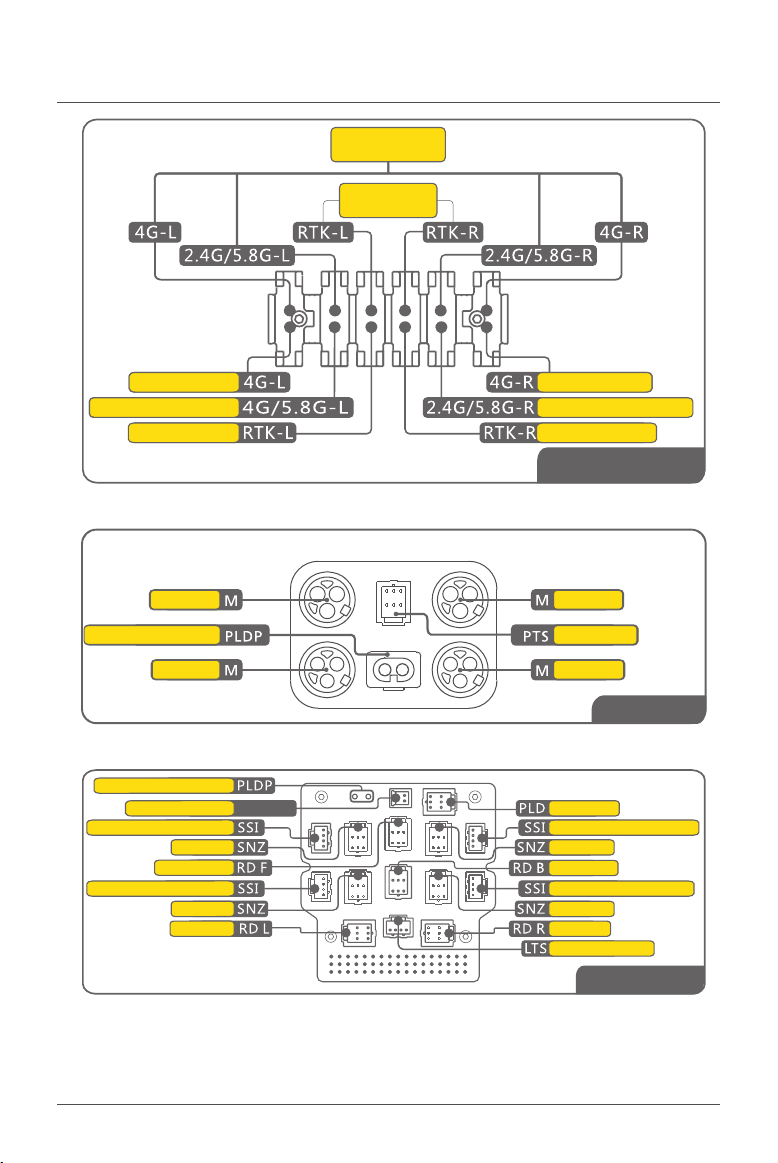

Insert RTK feeder and 2.4/5.8GHz feeder into

the No.3 short arm first, insert the arm from

designated position of the airframe plate, and

then install top slider and arm fasteners back to

their original position to complete assembling of

No.3 short arm.