XIEGU Product Maintenance Manual G90/G90S Portable Short-Wave Transceiver

XIEGU All Rights Reserved Version No.: 1.0 2022-07 Page 6of 48

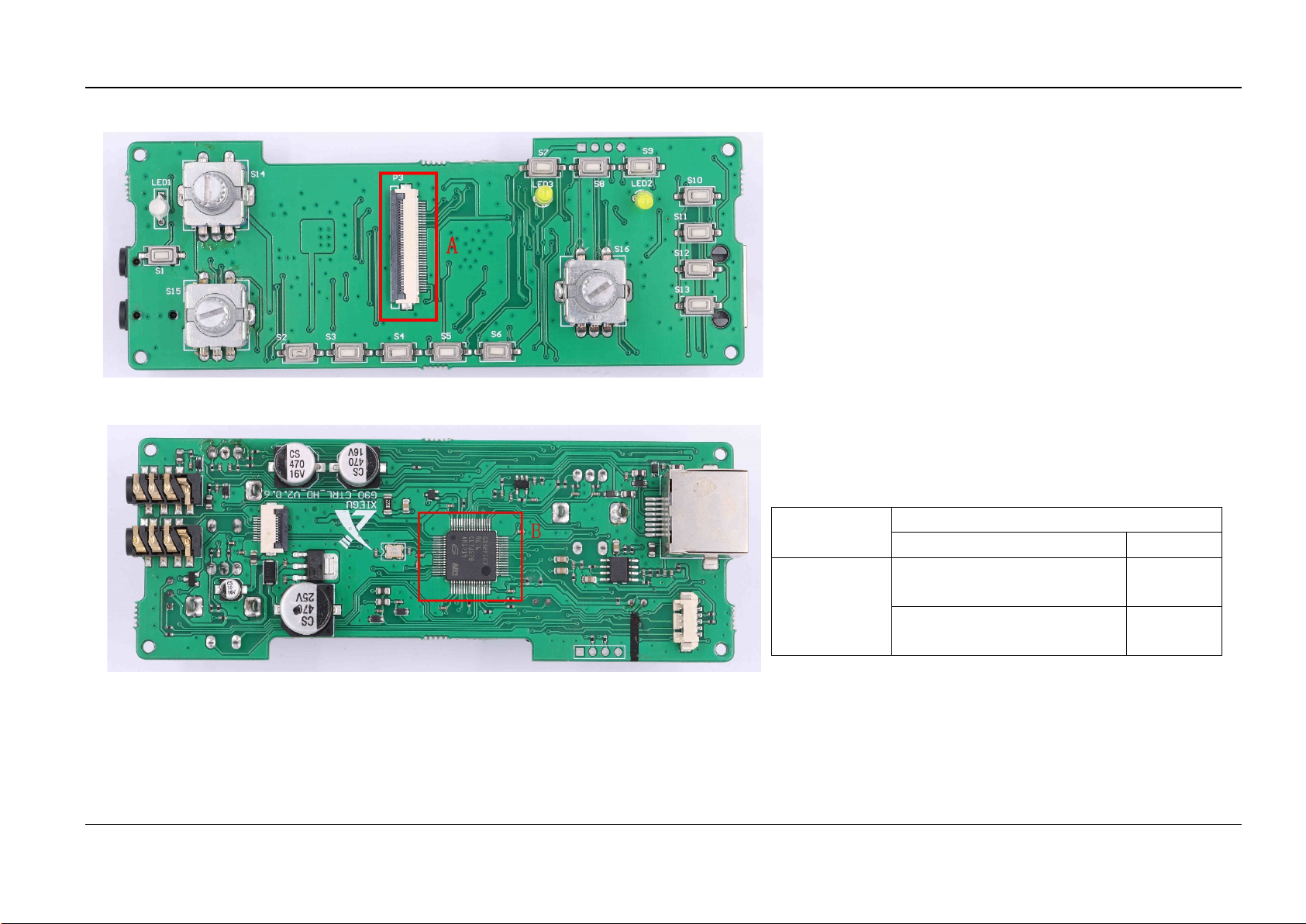

The head of G90 can be separated from its body, with hot swap supported. Therefore, in the

maintenance process, this feature can be utilized to quickly locate whether the fault point is in the

main unit or the head unit.

The heads ofdifferent versions can be interchanged, andthe replacement method can be taken to

quickly locate whether it is the fault of the head.

Main troubleshooting methods:

Check according to the signal flow direction: Check step by step along the signal flow to find

abnormalities.

Judge based on voltage/ current: According to the measured voltage or current, quickly and

roughly judge whether the product has a short circuit/ open circuit. Take full advantage of thermal

imager to troubleshoot short-circuit points.

Component-level inspection: Perform fault inspection according to the inherent characteristics

of components.

To sum up, the maintenance personnel need to have a comprehensive understanding of the overall

structure, signal flow, unit function, and operation method of the product, and at the same time arm

themselves with certain basic knowledge of module and circuit.