Page: 4

Technical presentation

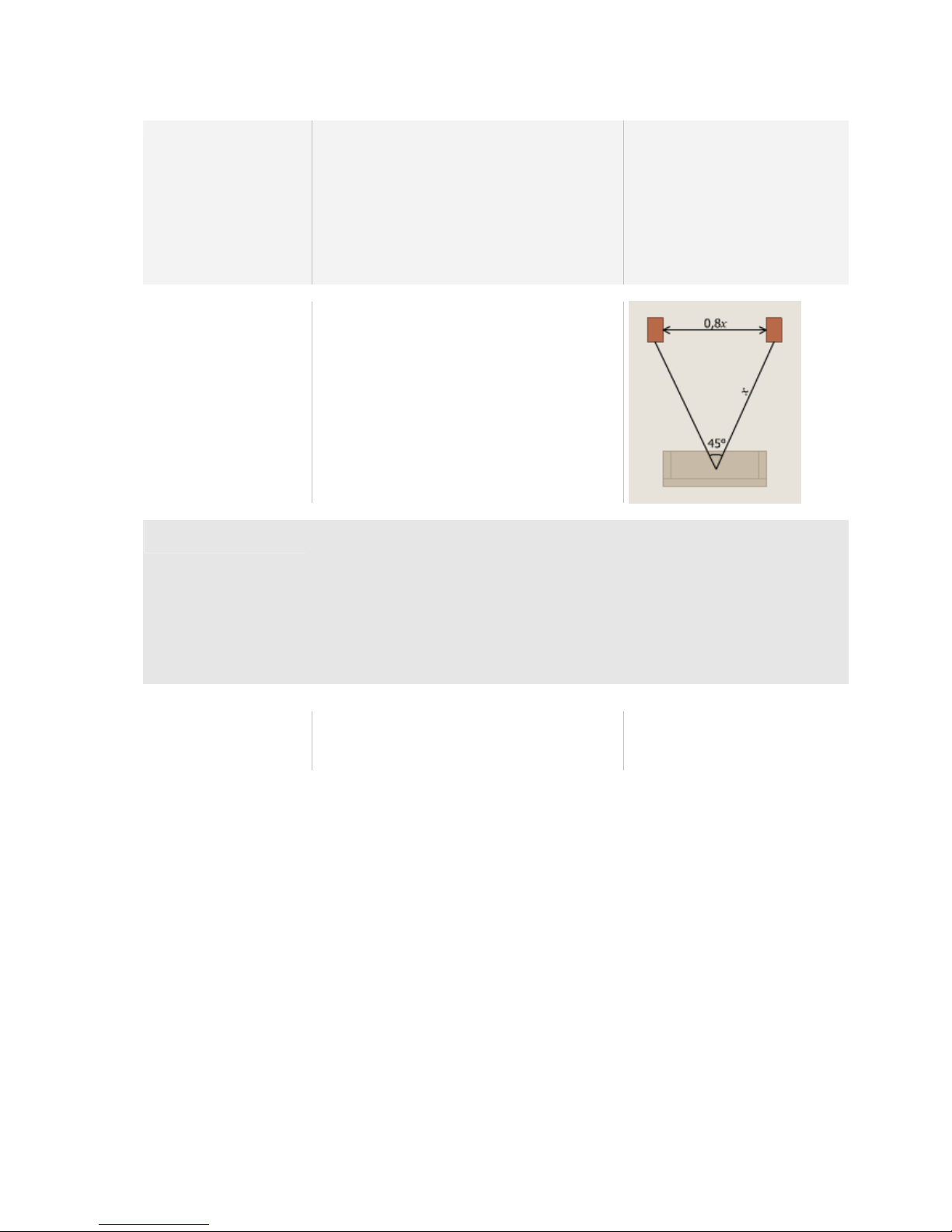

Cabinet design

The box design with a narrow baffle -

aesthetically neat shape, b t also has some ad

in terms of aco stics.

The cabinet is made from st rdy

offers good sonic q alities.

The cabinet is f rther strengthened

which in total ens res a very stable constr ction.

We have selected a ribbon tweeter which provides

s perior transient response and a very flat

freq ency response. The ribbon cone is s per light

and only 18 microns thick. It is a sandwich

constr ction made from rosin-al mini m-rosin

that has been hardened at 320 degrees Celsi s.

The magnet system is a 2 row high-efficient

neodymi m magnets in a mo lded chassis of

ceramic carbon steel.

Fishbone shaped contactors in al mini m, res lts

in a low connection resistance and good heat

distrib tion.

The driver has high power d rability and handles

freq encies p to 40000 Hz which makes it DVD-

A dio and SACD-ready.

After eval ating a large n mber of drivers from

different man fact rers we selected one from Seas,

a company that has a solid rep tation in the area of

high q ality speaker drivers. Yo find Seas drivers

in many well-known High End speakers.

For woofer/midrange we decided on a 6,5"

magnesi m driver from the Seas Excel series that

have extreme performance. We claim that finding a

better 6,5" driver on the market is a very diffic lt

task.

The s rface treated magnesi m cone is extremely

light b t still extremely stiff and effectively red ces

resonances.

The r bber s rro nding makes s re that no edge

resonances are present.

The mo lded metal basket is a

is aco stically transparent with high precision as

the basket is shaped exactly d e to the mo lding

process. This makes s re that the basket is very

stable and efficiently red ces resonances. The

basket is absol tely non-magnetic, which

contrib tes to a higher efficiency of the driver.

A strong magnet combined with the light cone

ens res a high efficiency and a good transient

response.

Heavy copper rings mo nted above and below the

T-shaped pole piece red ce non linear- and

mod lation-distortion and increases the overload

margin.

The copper plating of the top and bottom plates