i 143926(A)

Table of Contents

CHAPTER 1 – INTRODUCTION ...................................................................................................................................1

GENERAL INFORMATION.................................................................................................................................................1

Standard Features .................................................................................................................................................1

LCD Display...........................................................................................................................................................1

Touch Screen.........................................................................................................................................................2

I/O PANEL....................................................................................................................................................................2

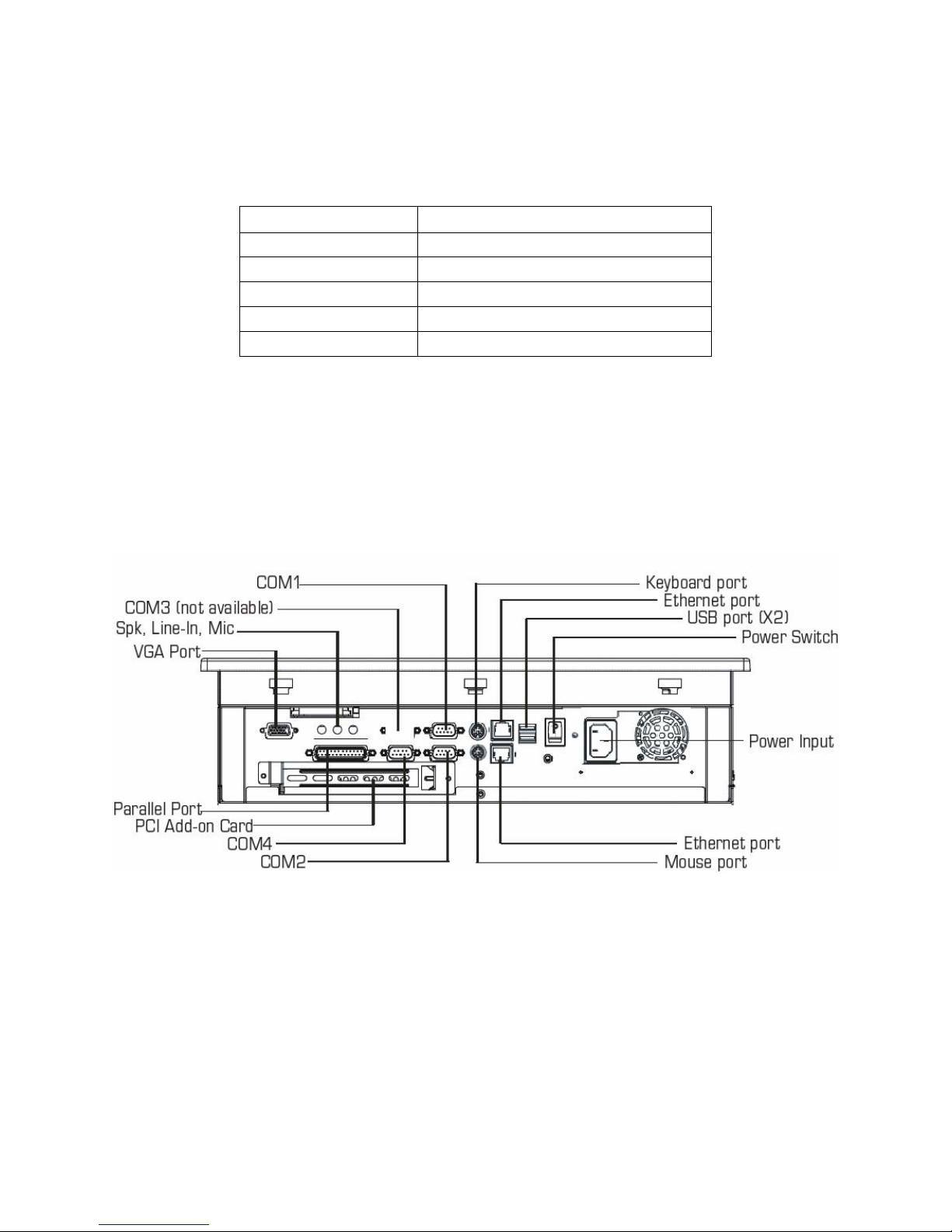

BACK PANEL ................................................................................................................................................................3

FRONT AND SIDE PANELS ..............................................................................................................................................4

UNPACKING THE SYSTEM...............................................................................................................................................5

QUICK STARTUP ...........................................................................................................................................................5

CHAPTER 2 — INSTALLATION...................................................................................................................................6

INSTALLATION OVERVIEW...............................................................................................................................................6

MECHANICAL DIMENSIONS .............................................................................................................................................8

MOUNTING OPTIONS .....................................................................................................................................................9

Panel Mounting......................................................................................................................................................9

Wall Mounting ......................................................................................................................................................11

Arm Mounting.......................................................................................................................................................13

CHAPTER 3 – POS-478 CPU BOARD AND AMI BIOS SETUP.................................................................................14

POS-478E CPU BOARD ............................................................................................................................................14

Product Overview.................................................................................................................................................14

Specifications.......................................................................................................................................................14

POS-478E CPU BOARD LAYOUT................................................................................................................................15

Jumper Settings...................................................................................................................................................16

Connector Pin Outs..............................................................................................................................................21

AMI BIOS SETUP.......................................................................................................................................................31

Starting Setup ......................................................................................................................................................31

Using Setup..........................................................................................................................................................32

Getting Help.........................................................................................................................................................32

Main Menu ...........................................................................................................................................................33

STANDARD CMOS SETUP ...........................................................................................................................................34

Advanced CMOS Setup.......................................................................................................................................36

ADVANCED CHIPSET SETUP.........................................................................................................................................39

POWER MANAGEMENT SETUP......................................................................................................................................41

PCI /PLUG AND PLAY SETUP.......................................................................................................................................42

PERIPHERAL SETUP ....................................................................................................................................................43

Hardware Monitor Setup ......................................................................................................................................44

CHAPTER 4 – MAINTENANCE...................................................................................................................................46

GENERAL PREVENTIVE MAINTENANCE ..........................................................................................................................46

Fuse Replacement...............................................................................................................................................46

RECOMMENDED HARD DRIVE PREVENTIVE MAINTENANCE ..............................................................................................46

PRODUCT REPAIR PROGRAM /RETURNING A UNIT TO XYCOM AUTOMATION .....................................................................47

CHAPTER 5 – TROUBLESHOOTING.........................................................................................................................48

DIAGNOSTIC TESTING..................................................................................................................................................48

RUNNING THE TESTS...................................................................................................................................................50

REINSTALLING OPERATING SYSTEMS............................................................................................................................51

Windows

®

2000 Reinstallation .............................................................................................................................51

Windows XP®Reinstallation.................................................................................................................................51

INSTALLING DRIVERS...................................................................................................................................................52

Video Drivers........................................................................................................................................................52

Touch Screen Drivers ..........................................................................................................................................52

Miscellaneous Drivers..........................................................................................................................................53