Table of contents

1 Introduction................................................................................................................7

1.1 Manual history.................................................................................................................................................7

1.2 Information about this document.................................................................................................................... 9

1.2.1 Organization of notices..............................................................................................................................9

1.2.2 Guidelines.................................................................................................................................................. 9

2 General safety guidelines...................................................................................... 10

2.1 Intended use................................................................................................................................................. 10

2.2 Protection against electrostatic discharge.................................................................................................... 10

2.2.1 Packaging................................................................................................................................................ 10

2.2.2 Regulations for proper ESD handling..................................................................................................... 10

2.3 Regulations and measures........................................................................................................................... 11

2.4 Transport and storage.................................................................................................................................. 11

2.5 Installation..................................................................................................................................................... 11

2.6 Operation.......................................................................................................................................................12

2.6.1 Protection against contact with electrical parts.......................................................................................12

2.6.2 Ambient conditions - Dust, moisture, aggressive gases......................................................................... 12

2.6.3 Programs, viruses and malicious programs............................................................................................12

2.7 Cybersecurity disclaimer for products...........................................................................................................13

3 System overview..................................................................................................... 14

3.1 About this user's manual.............................................................................................................................. 14

3.2 Description of individual modules................................................................................................................. 14

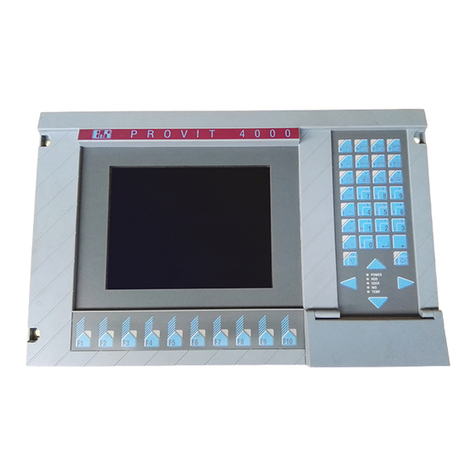

3.2.1 AP9x3 panels.......................................................................................................................................... 14

3.2.2 Link modules........................................................................................................................................... 14

3.3 Design/Configuration..................................................................................................................................... 15

3.3.1 Order number key................................................................................................................................... 15

3.4 Overview........................................................................................................................................................16

4 Technical data......................................................................................................... 17

4.1 Complete system.......................................................................................................................................... 17

4.1.1 Connection options..................................................................................................................................17

4.1.1.1 SDL operation.................................................................................................................................... 17

4.1.1.2 DVI operation..................................................................................................................................... 19

4.1.1.3 SDL3 operation.................................................................................................................................. 21

4.1.1.4 SDL4 operation.................................................................................................................................. 22

4.1.2 Electrical properties................................................................................................................................. 24

4.1.2.1 Power calculation...............................................................................................................................24

4.1.2.2 Block diagrams...................................................................................................................................25

4.1.3 Mechanical properties..............................................................................................................................26

4.1.3.1 Dimensions.........................................................................................................................................26

4.1.3.2 Installation diagrams.......................................................................................................................... 27

4.1.3.3 Spacing for air circulation.................................................................................................................. 28

4.1.3.4 Mounting orientations.........................................................................................................................29

4.1.3.5 Weight specifications......................................................................................................................... 29

4.1.4 Environmental properties.........................................................................................................................30

4.1.4.1 Temperature specifications................................................................................................................ 30

4.1.4.2 Relative humidity................................................................................................................................33

4.1.4.3 Vibration and shock........................................................................................................................... 33

4.1.4.4 Degree of protection.......................................................................................................................... 33

4.1.5 Device interfaces..................................................................................................................................... 34

4.1.5.1 SDL/DVI receiver (5DLSDL.1001-00)................................................................................................ 34

4.1.5.2 SDL3 receiver (5DLSD3.1001-00).....................................................................................................40

4.1.5.3 SDL4 receiver (5DLSD4.1001-00).....................................................................................................43

4.2 Individual components.................................................................................................................................. 46

4.2.1 Panels...................................................................................................................................................... 46

4.2.1.1 5AP923.1215-00.................................................................................................................................46

Automation Panel 9x3 User's manual 2.01 3