i 143311 (H)

Table of Contents

CHAPTER 1 – INTRODUCTION .................................................................................................................................1

PRODUCT OVERVIEW ..................................................................................................................................................1

STANDARD FEATURES .................................................................................................................................................1

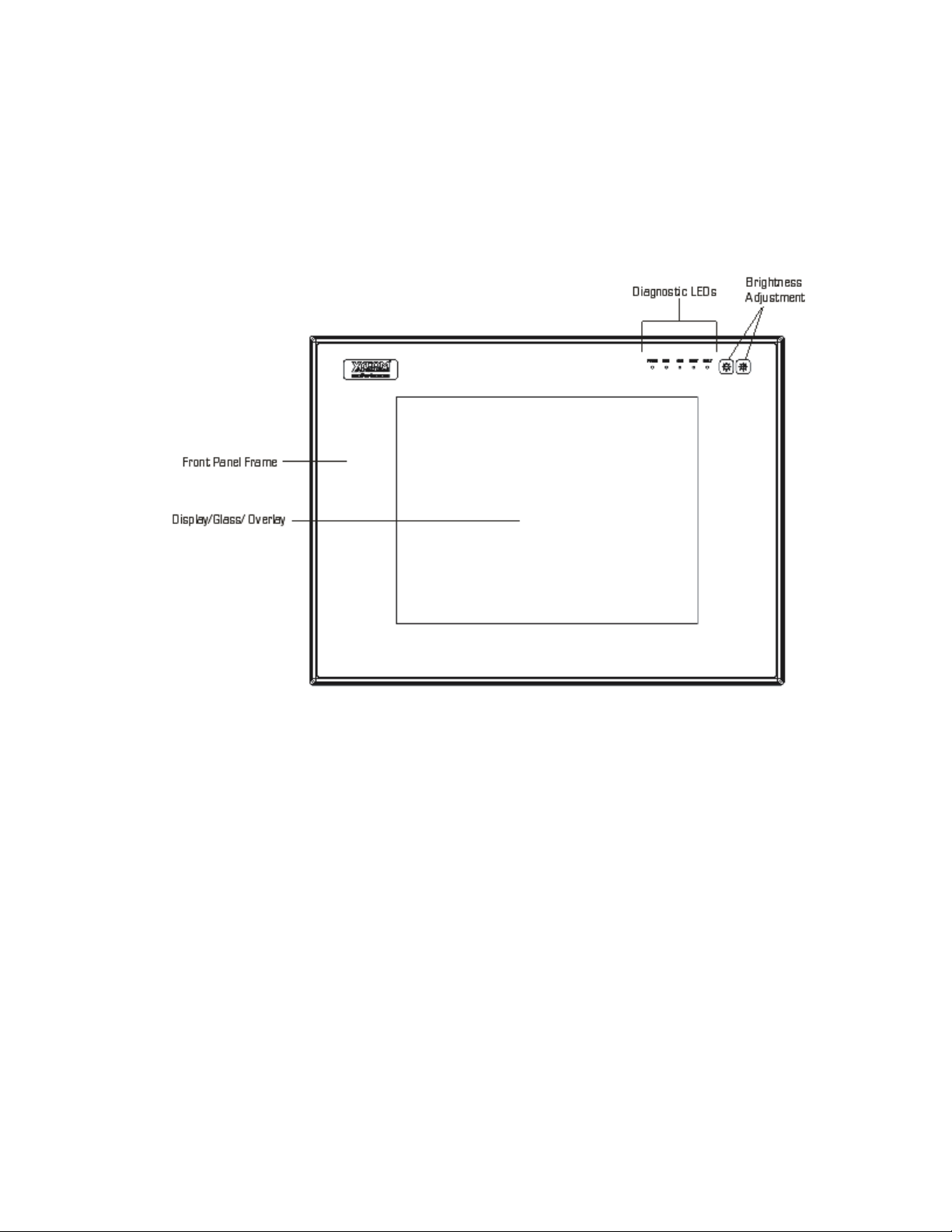

Front Panels.........................................................................................................................................................3

I/O Panel ..............................................................................................................................................................7

Back Panel...........................................................................................................................................................9

Power Panel.......................................................................................................................................................10

UNPACKING THE SYSTEM ...........................................................................................................................................11

QUICK STARTUP .......................................................................................................................................................11

CHAPTER 2 – INSTALLATION.................................................................................................................................12

INSTALLATION OVERVIEW...........................................................................................................................................12

SYSTEM CUTOUT DIMENSIONS....................................................................................................................................14

3712kpm(t).........................................................................................................................................................14

3715T& 3715KPM(T)...........................................................................................................................................15

POWER MANAGEMENT...............................................................................................................................................16

System Power....................................................................................................................................................16

Excessive Heat ..................................................................................................................................................17

Electrical Noise ..................................................................................................................................................17

Line Voltage Variation........................................................................................................................................18

AC Power Cable ................................................................................................................................................18

INSTALLING INTERNAL HARDWARE OPTIONS ................................................................................................................19

DRAM and Additional DRAM Dual Inline Memory Modules (DIMMs) ................................................................20

PC/AT™and PCI Boards....................................................................................................................................20

USING A TOUCH SCREEN ...........................................................................................................................................20

Installing the Touch Screen Driver.....................................................................................................................21

Calibrating the Touch Screen ............................................................................................................................22

CUSTOM LOGO .........................................................................................................................................................23

CREATING CUSTOM KEYPAD INSERTS .........................................................................................................................23

HAZARDOUS LOCATIONS INSTALLATION .......................................................................................................................29

Safety Agency Approval.....................................................................................................................................29

Definitions ..........................................................................................................................................................31

Class I Locations................................................................................................................................................31

Class II Locations...............................................................................................................................................31

Division 1 Locations...........................................................................................................................................31

Division 2 Locations...........................................................................................................................................31

Groups ...............................................................................................................................................................32

Enclosures .........................................................................................................................................................32

Power Switch .....................................................................................................................................................33

Cable Connections.............................................................................................................................................33

Communication Cable Interfaces.......................................................................................................................33

Hazardous Locations Control Drawing...............................................................................................................34

Operation and Maintenance...............................................................................................................................35

CHAPTER 3 – KEYPAD UTILITY PROGRAM..........................................................................................................36

LOADING THE KEYPAD UTILITY....................................................................................................................................36

USING THE KEYPAD UTILITY .......................................................................................................................................36

STARTUP .................................................................................................................................................................37

MAIN MENU ..............................................................................................................................................................37

Exit .....................................................................................................................................................................38

Files Menu .........................................................................................................................................................38

Macros Menu .....................................................................................................................................................39

Upload Menu......................................................................................................................................................41

Download Menu .................................................................................................................................................41

Utilities Menu .....................................................................................................................................................42

UTILITY BATCH MODE ................................................................................................................................................42

KEYPAD SCAN CODES ...............................................................................................................................................43

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com