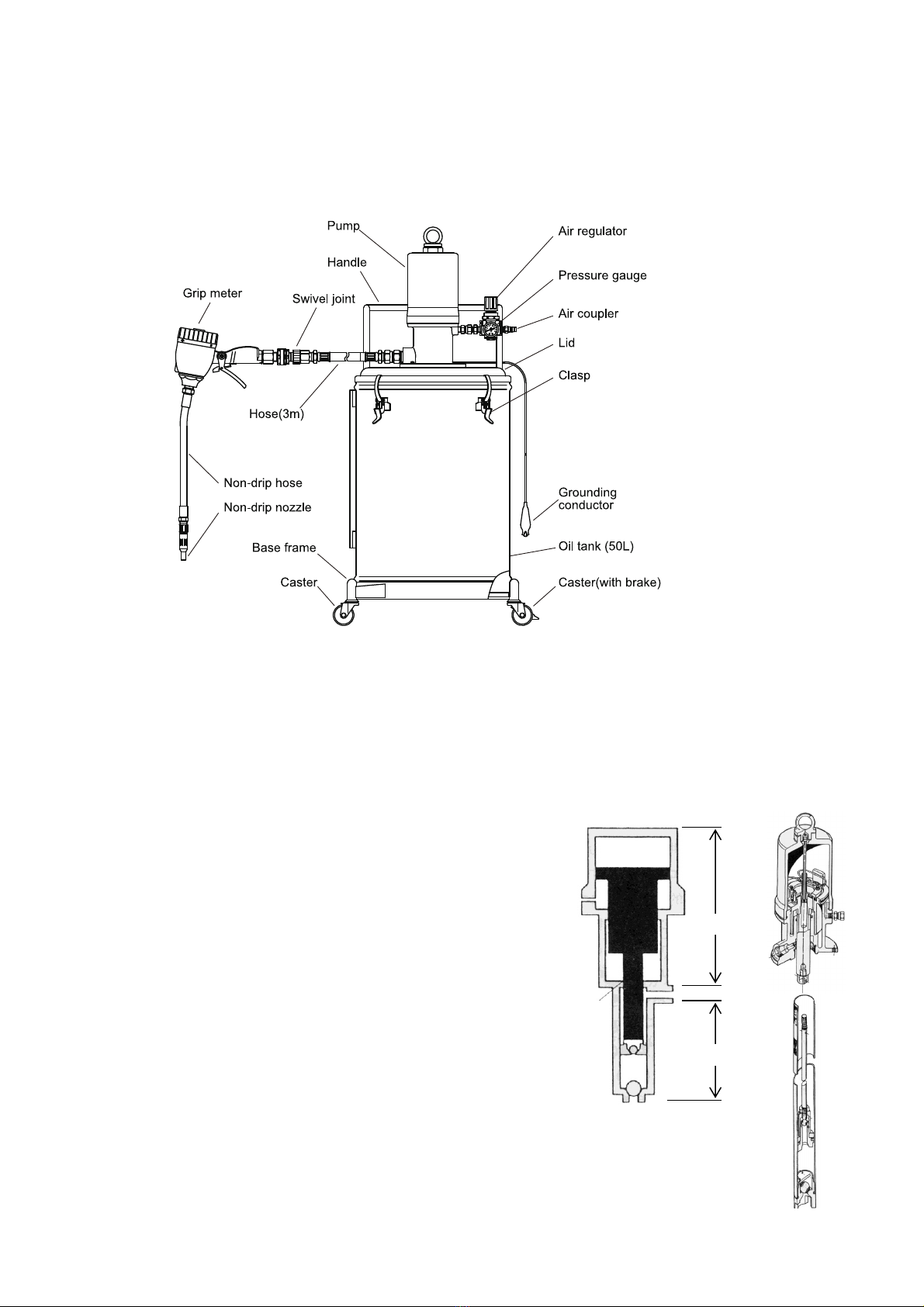

5

5.2 Maintenance and Inspection

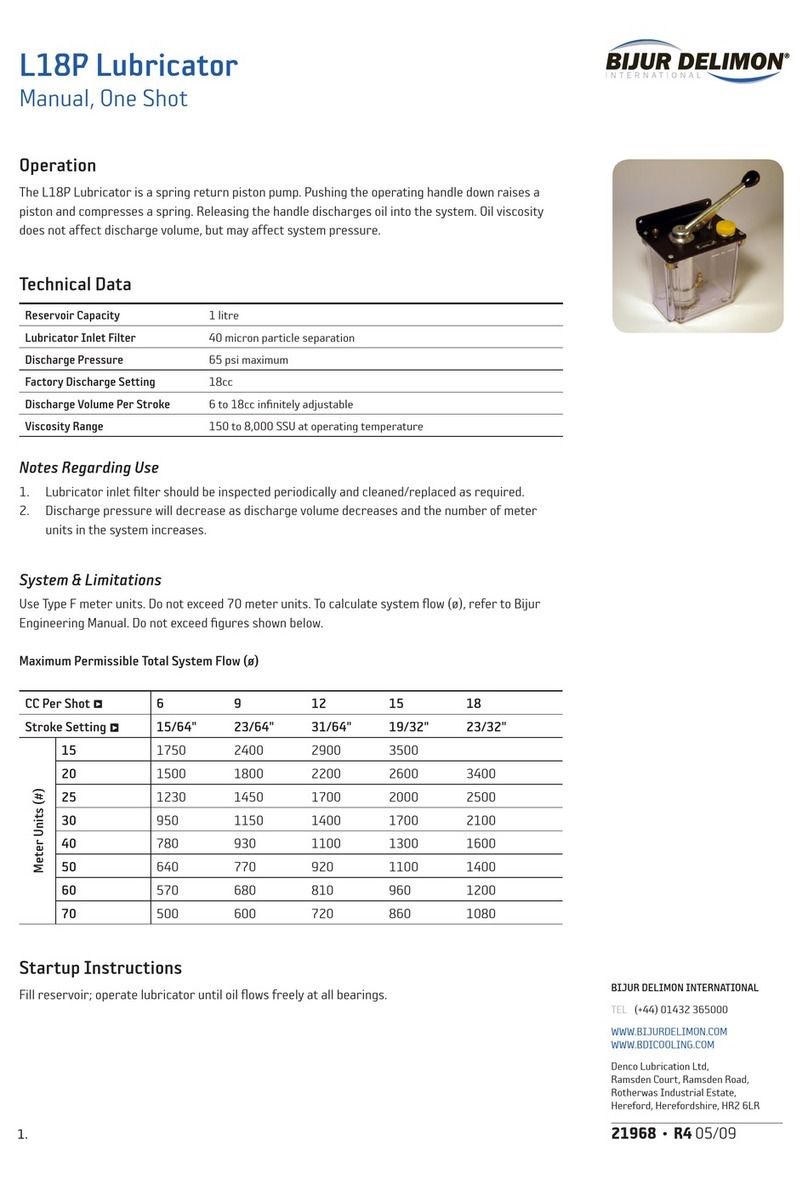

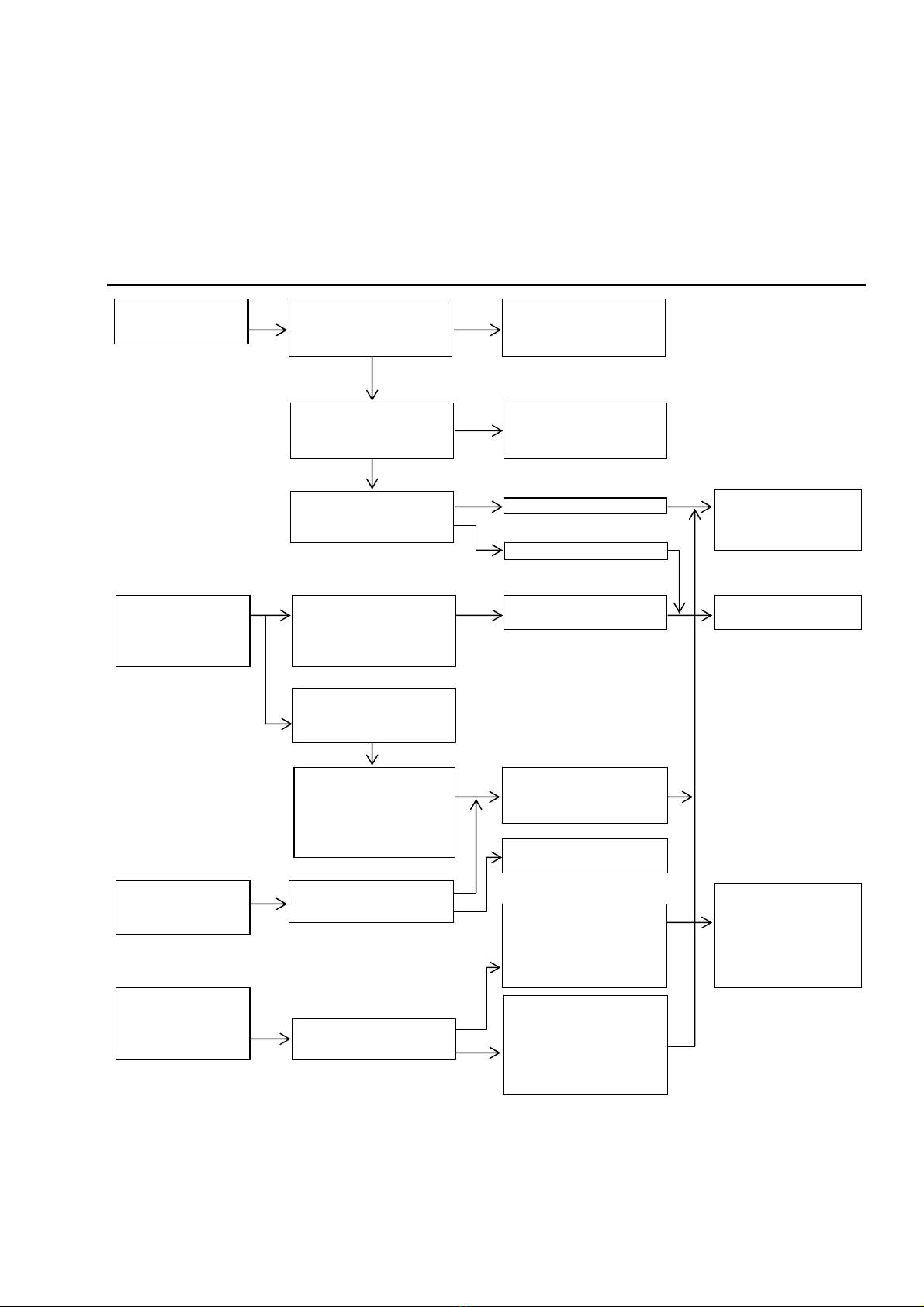

For lubrication of the pump, perform oiling once every 10 days with

lubricating oil. (Fig. 6)

Supply the lubricating oil as following.

1) Remove the air regulator.

2) Inject a few drops of lubricating oil (approx. 0.5 mL) into the air supply

port as shown in the figure at right. Use turbine oil class 1 ISO (VG-32)

or equivalent as the lubricating oil.

[Inspection]

-Oil is a fluid and easily polluted. Keep it clean at all times.

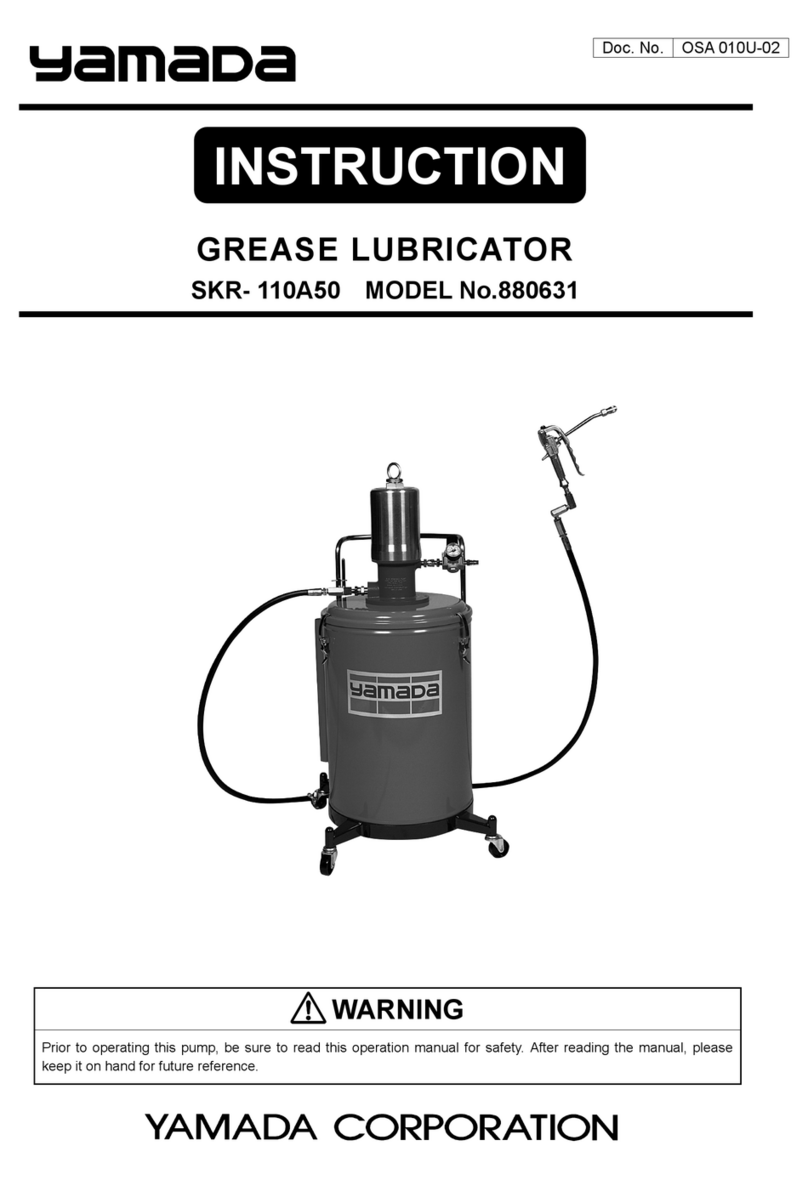

-To protect the flow meter, a filter is installed between the pump and the

flow meter. If filter clogging occurs, the oil flow is get worse. Clean the

filter sometimes. (Fig. 7)

-The oil-proof hose is a consumable product. Check it periodically. If any

blemish or leakage is found, replace the hose a little earlier.

-The packing of the pump will be worn away. Check and replace it at

least once a year.

6. Disassembly and Assembly

-When the pump operation becomes defective or stops, do not disassemble the pump thoughtlessly, but refer to

the item on P.4 (Troubleshooting and Corrective Measures), and judge the condition carefully and disassemble

only the minimum necessary parts.

-The air motor is rarely touched directly, so its failure rate is very low. The air motor does not need to be

disassembled. If disassembling is required, ask the dealer to disassemble the air motor.

WARNING

- Gasoline is a high-volatility material. Do not use gasoline to clean the pump in any case, otherwise it

may cause ignition or explosion.

- Before starting disassembling or inspecting the machine, be sure to shut off the supply air and open

the outlet valve to release the internal pressure of the machine.

- When washing parts, do not use such a liquid as corrodes aluminum, copper alloy, iron, etc.

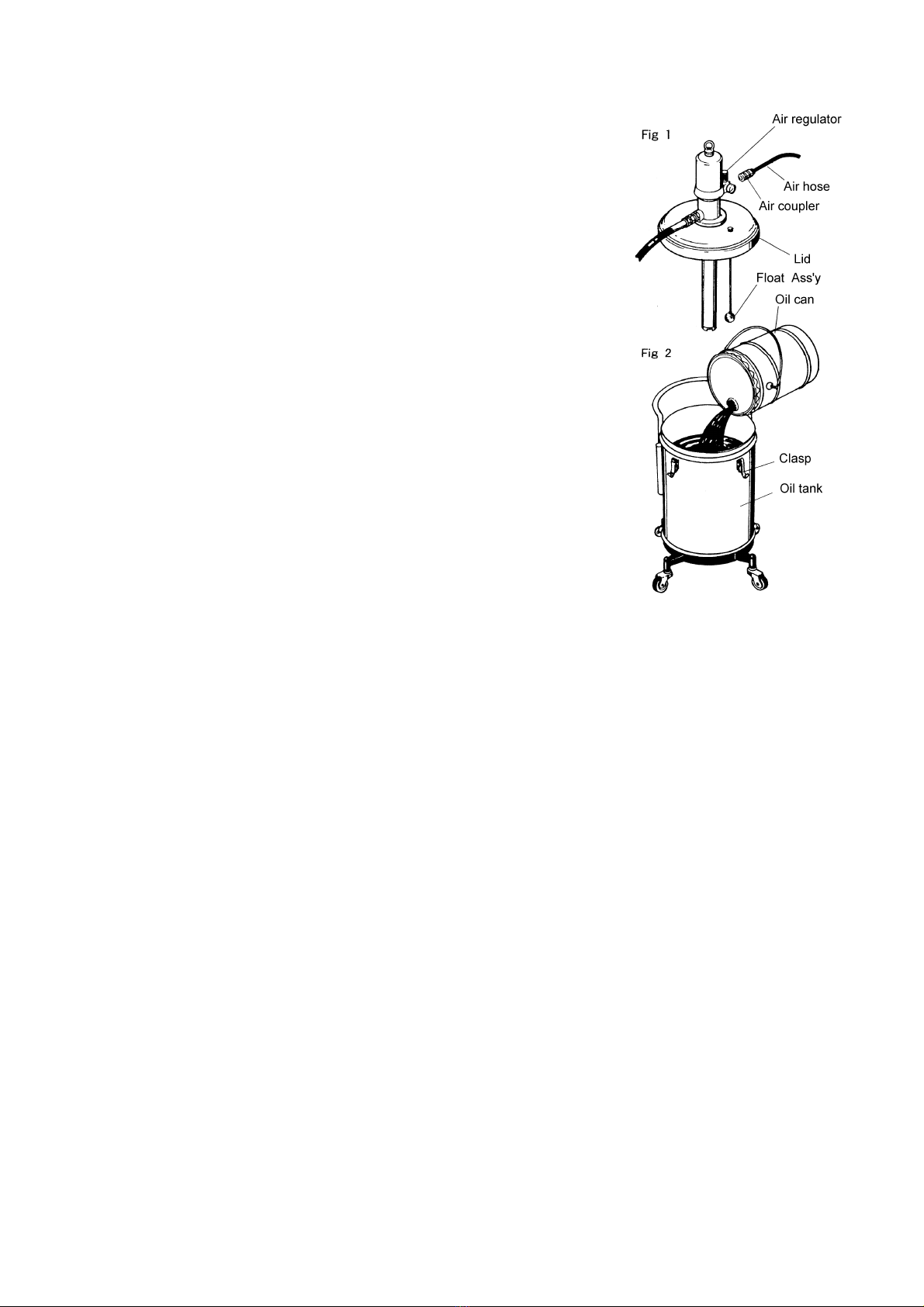

6.1 Disassembling the Air Motor and the Lower Pump

1) Shut off the air that is supplied to the pump and bleed the internal

pressure of the pump.

2) Remove the oil-proof hose and the air hose from the pump.

3) Release the 3 clasp on the top of the oil tank upward, and remove

the lid together with the pump.

4) Unscrew the 5 bolts (on the rear side of the lid) that fix the pump

Assy and the lid and separate the pump Assy from the lid.

Bleed the oil remaining in the tube by pushing up the ball in the

foot valve with a finger.

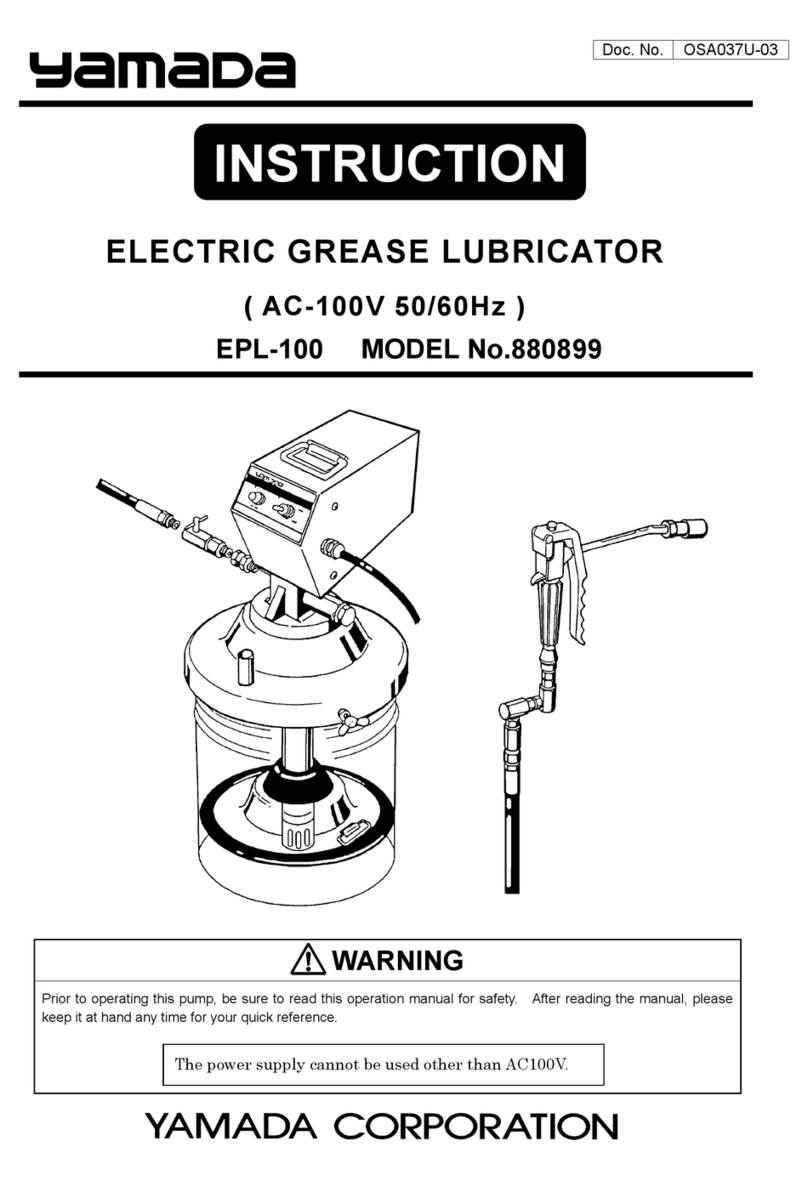

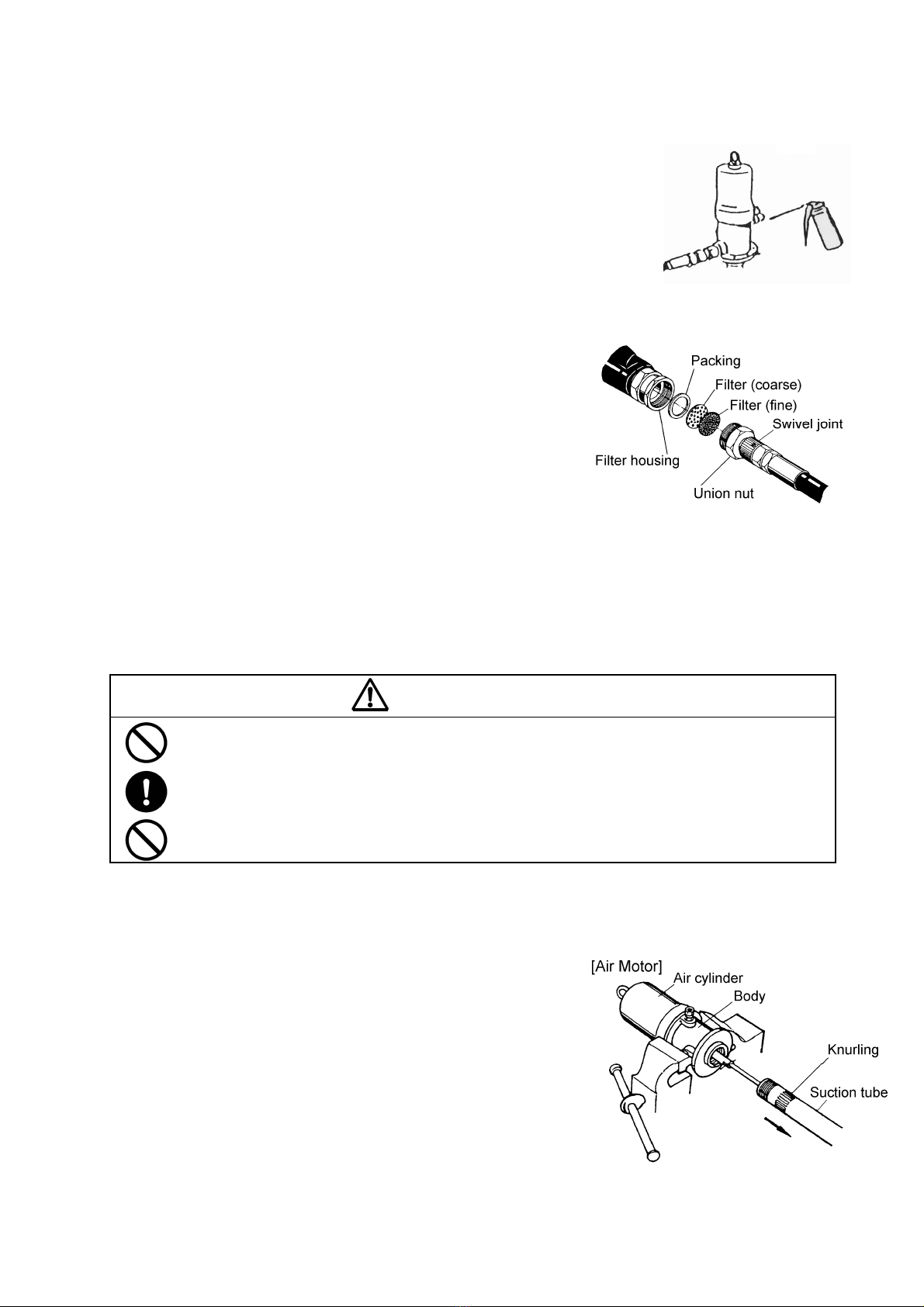

5) Fix the air motor body of the pump on the vise and set a pipe

wrench on the knurling section in the upper part of the suction

tube of the lower pump and unscrew it. (Fig. 8)

<NOTE>

The air cylinder is easily blemished. Do not fix it on the vise.

Fig.6

Fig.7

Fig.8