2/3

- Precautions on Use

The following warnings and cautions are very important. Be sure to observe them.

WARNING

- The operator and maintenance engineer should read the operation manual thoroughly before operating

this product and performing maintenance in respect of this product.

- Always wear proper safety equipments (facemask, ear plugs, and safety shoes, etc.) when installing,

operating and disassembling this product.

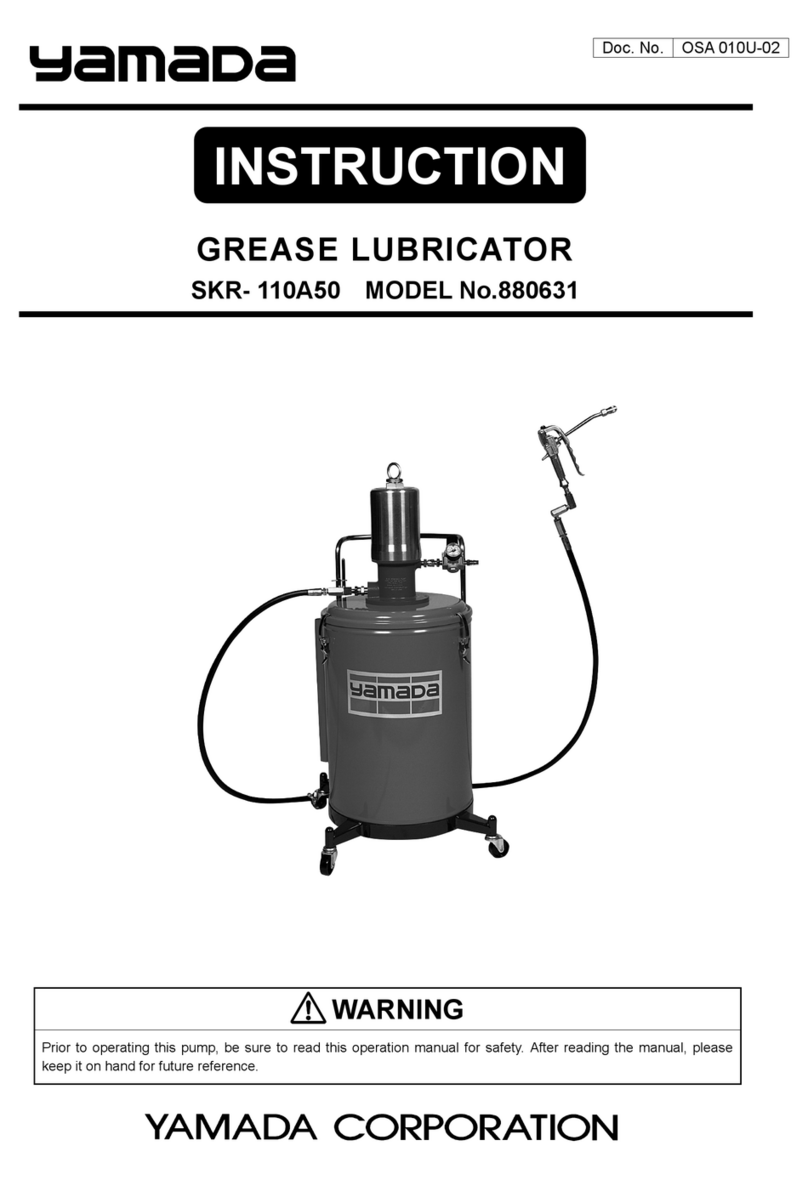

- Lock caster's stopper during and after the work, so that this product should not move unexpectedly.

Also, do not use or leave this product in a slope or any unstable locations. This product moves freely

when the caster is not locked and the damage only accident and the facilities pollution, etc. might occur.

Such a secondary disaster becomes a responsibility on the user side.

- Make ground connection when working with flammable material or in explosive atmosphere. Rapid

pumping of material can result in static electrical charge.

Also, be sure to provide proper ventilation where a flammable atmosphere may exist.

- Execute the daily checkup.

- Use this product according to the product specification.

- Attach a valve (for stop in emergency) or regulator to the air supply pipe to keep supply air pressure

under 0.7MPa.

- Be careful not to drop the cabinet when lifting it up to replace a pail. Catching a falling cabinet may

cause hand injury by its edge.

- Make sure the valve of the oil gun is closed before running the pump. Operating with the valve open

can cause a hose runaway.

- Discontinue it when you feel a hazard or abnormality during the work. And correspond according to the

troubleshooting.

- Keep your face away from the exhaust and discharge ports. Material may suddenly come out. There is

a possibility of losing eyesight if it strikes eyes.

- Stop pump operation immediately when a drum becomes empty. Running the pump dry will cause

excessive vibration, resulting in reduction of pump life and damage to other equipment.

- Be very careful not to drop the grease gun. It may become damaged, resulting in leakage and

malfunction.

- Do not aim exhalation part of this product at any person. Residual pressure may be left inside the gun

even when the pump is not in operation. There is a possibility of losing eyesight if it strikes eyes.

- Before maintenance operation, be sure to stop air from being supplied to the pump, and release the

internal pressure (both air and material) of the pump. There is danger such as spouting of the material

when the maintenance work is done with air supplied.

- Gasoline is a high volatile fuel. Do not use it to clean the pump in any case, otherwise ignition or

explosion may be caused.

- Modification of this pump may lead to death, bodily injury, or a failure. Do not modify it in any case

because it involves a risk.

- Do not discharge material directly onto the ground. Dispose of harmful materials according to the

requirements specified in MSDS or local regulations. Also, dispose of this product according to the local

regulations after removing residual material from inside this product. (Please contact industrial waste

disposal service.)