GEN

INFO

60V3E11

General information

How to use this manual.................................................................................1-1

Manual format............................................................................................1-1

Symbols.....................................................................................................1-2

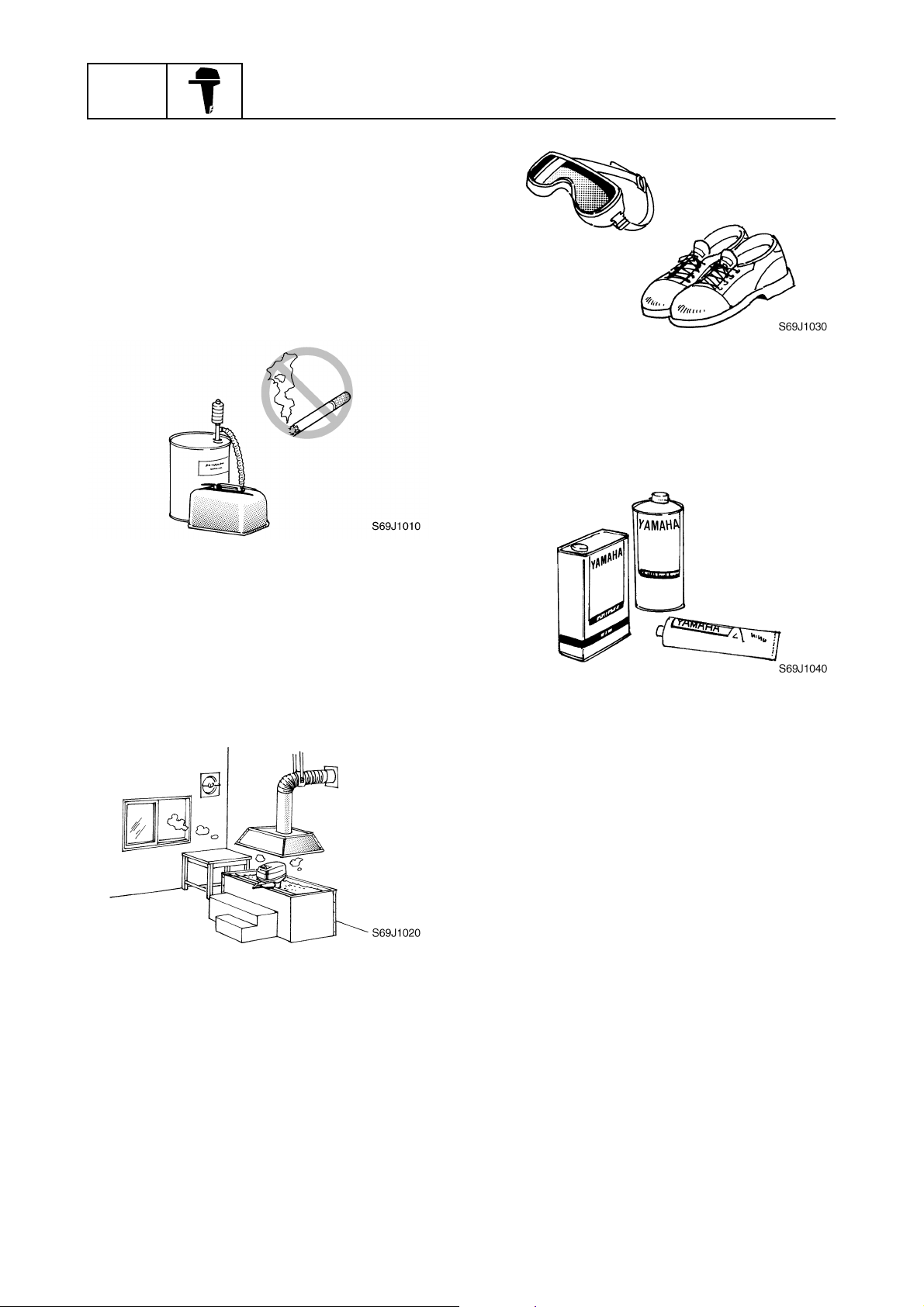

Safety while working......................................................................................1-3

Fire prevention...........................................................................................1-3

Ventilation..................................................................................................1-3

Self-protection ...........................................................................................1-3

Parts, lubricants, and sealants ..................................................................1-3

Good working practices .............................................................................1-4

Disassembly and assembly .......................................................................1-4

Identification...................................................................................................1-5

Applicable models .....................................................................................1-5

Serial number ............................................................................................1-5

Features and benefits....................................................................................1-6

Cylinder body and cylinder head ...............................................................1-6

Pistons and connecting rods .....................................................................1-7

Fuel injection pumps..................................................................................1-8

Flywheel magnet .......................................................................................1-9

ECM (Electronic Control Module) ............................................................1-10

Injector drivers .........................................................................................1-12

Idle silencer .............................................................................................1-13

Power unit mounting bolts .......................................................................1-14

Cooling water inlet ...................................................................................1-15

Transmission components.......................................................................1-16

Technical tips ...............................................................................................1-17

Electronic control system.........................................................................1-17

Partial cylinder operation .........................................................................1-18

Fail-safe control .......................................................................................1-19

Warning control .......................................................................................1-20

Over-revolution control ............................................................................1-20

Shift cut control........................................................................................1-20

Propeller selection.......................................................................................1-21

Propeller size...........................................................................................1-21

Selection..................................................................................................1-21