Table of contents

1 Basics...................................................................................................................... 5

1.1 Copyright © VIPA GmbH ................................................................................. 5

1.2 About this manual............................................................................................. 6

1.3 Safety information............................................................................................. 7

2 Assembly and installation guidelines.................................................................. 8

2.1 Safety information for users.............................................................................. 8

2.2 Overview........................................................................................................... 9

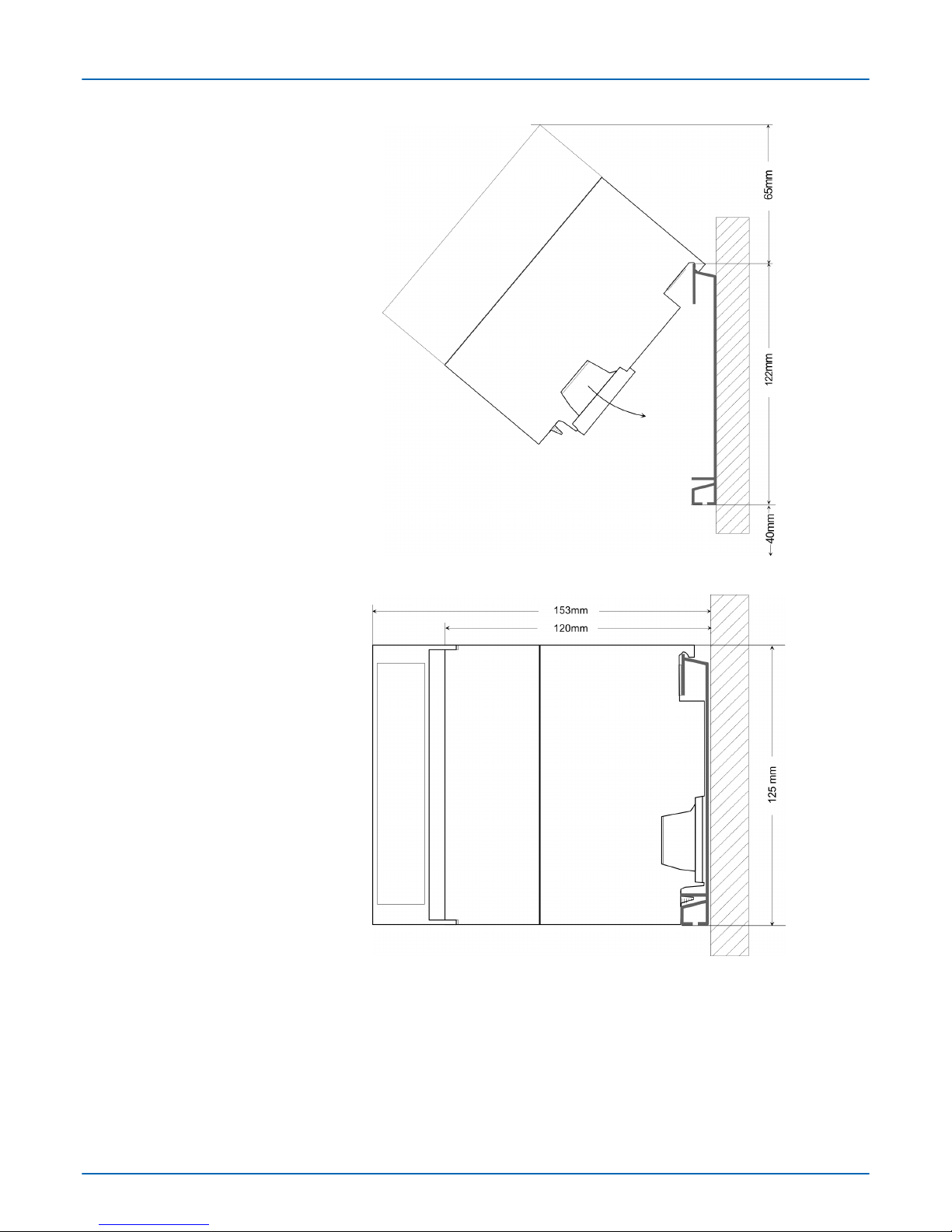

2.3 Installation dimensions..................................................................................... 9

2.4 Assembly SPEED-Bus.................................................................................... 11

2.5 Assembly standard bus.................................................................................. 14

2.6 Cabling........................................................................................................... 16

2.7 Installation guidelines..................................................................................... 19

2.8 General data I/O modules.............................................................................. 21

2.8.1 General data................................................................................................ 22

3 Digital Input Modules........................................................................................... 24

3.1 321-1BH01 - DI 16xDC 24V........................................................................... 24

3.1.1 Technical data.............................................................................................. 25

3.2 321-1BL00 - DI 32xDC 24V............................................................................ 27

3.2.1 Technical data.............................................................................................. 29

3.3 321-1FH00 - DI 16xAC120/230V.................................................................... 31

3.3.1 Technical data.............................................................................................. 33

4 Digital Output Modules........................................................................................ 35

4.1 Safe shutdown of non-safe outputs................................................................ 35

4.1.1 Introduction.................................................................................................. 35

4.1.2 Safe shutdown............................................................................................. 35

4.1.3 Requirements and fault exclusions.............................................................. 36

4.2 322-1BF01 - DO 8xDC 24V 2A...................................................................... 38

4.2.1 Technical data.............................................................................................. 39

4.3 322-1BH01 - DO 16xDC 24V 1A.................................................................... 41

4.3.1 Technical data.............................................................................................. 43

4.4 322-1BH41 - DO 16xDC 24V 2A.................................................................... 45

4.4.1 Technical data.............................................................................................. 48

4.5 322-1BH60 - DO 16xDC 24V 0.5A for manual operation............................... 50

4.5.1 Deployment................................................................................................. 52

4.5.2 Technical data.............................................................................................. 52

4.6 322-1BL00 - DO 32xDC 24V 1A .................................................................... 54

4.6.1 Deployment................................................................................................. 57

4.6.2 Technical data.............................................................................................. 57

4.7 322-5FF00 - DO 8xAC 120/230V 2A ............................................................. 59

4.7.1 Parameterization ........................................................................................ 62

4.7.2 Technical data.............................................................................................. 63

4.8 322-1HH00 - DO 16xRelay ............................................................................ 65

4.8.1 Technical data.............................................................................................. 68

5 Digital Input/Output Modules.............................................................................. 71

5.1 323-1BH00 - DIO 16xDC 24V 1A................................................................... 71

5.1.1 Technical data.............................................................................................. 73

5.2 323-1BH01 - DI 8xDC 24V, DO 8xDC 24V 1A............................................... 75

VIPA System 300S Table of contents

HB140 | SM-DIO | | en | Rev. 16-43 3