IM 1M12A01-02E

viii

3. Installation .................................................................................................................... 3-1

3.1 Installation of the Detector ............................................................................. 3-1

3.1.1 Location ................................................................................................... 3-1

3.1.2 Probe Insertion Hole................................................................................ 3-1

3.1.3 Installation of the Detector...................................................................... 3-2

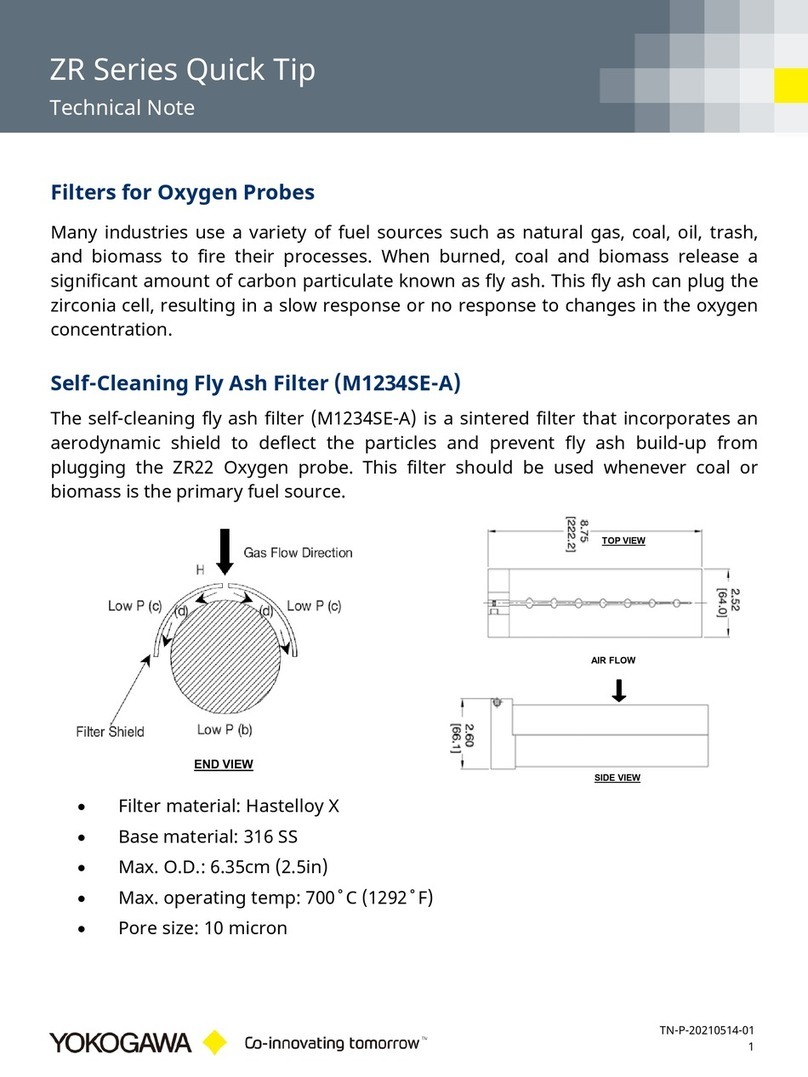

3.1.4 Installation of the Dust Filter( Part No K9471UA)................................ 3-3

3.2 Installation of the Detector (Model ZR22G-015)........................................... 3-5

3.2.1 Installation Location ................................................................................ 3-5

3.2.2 Usage of the High-temperature Probe Adapter (Model ZO21P-H) ....... 3-5

3.2.3 Probe Insertion Hole................................................................................ 3-7

3.2.4 Mounting of the High-Temperature Detector ......................................... 3-7

3.3 Installation of the Converter ........................................................................... 3-9

3.3.1 Location ................................................................................................... 3-9

3.3.2 Mounting of the Converter...................................................................... 3-9

3.4 Installation of ZA8F Flow Setting Unit ....................................................... 3-12

3.4.1 Location ................................................................................................. 3-12

3.4.2 Mounting of ZA8F Flow Setting Unit .................................................. 3-12

3.5 Installation of ZR40H Automatic Calibration Unit...................................... 3-14

3.5.1 Location ................................................................................................. 3-14

3.5.2 Mounting of ZR40H Automatic Calibration Unit ................................ 3-14

3.6 Installation of the Calibration Gas Unit Case (E7044KF) ........................... 3-16

3.6.1 Location ................................................................................................. 3-16

3.6.2 Mounting................................................................................................ 3-16

3.7 Insulation Resistance Test............................................................................. 3-17

3.8 External Dimensions of Detectors with Pressure Compensation................. 3-18

4. Piping............................................................................................................................. 4-1

4.1 Piping for System 1 ........................................................................................ 4-1

4.1.1 Parts Required for Piping in System 1 ................................................... 4-2

4.1.2 Connection to the Calibration Gas Inlet ................................................. 4-3

4.1.3 Connection to the Reference Gas Inlet ................................................... 4-3

4.1.4 Piping to the High-temperature Probe Adapter ...................................... 4-4

4.2 Piping for System 2 ........................................................................................ 4-6

4.2.1 Piping Parts for System 2........................................................................ 4-7

4.2.2 Piping for the Calibration Gas ................................................................ 4-8

4.2.3 Piping for the Reference Gas .................................................................. 4-8

4.2.4 Piping to the High-temperature Probe Adapter ...................................... 4-8

4.3 Piping for System 3 ........................................................................................ 4-9

4.3.1 Blow Back Piping.................................................................................. 4-10

4.4 Piping for the Detector with Pressure Compensation .................................. 4-12

4.4.1 Piping Parts for a System using Detector with Pressure Compensation4-14

4.4.2 Piping for the Calibration Gas .............................................................. 4-14

4.4.3 Piping for the Reference Gas ................................................................ 4-14

5. Wiring ........................................................................................................................... 5-1

5.1 General ............................................................................................................ 5-1

5.1.1 Terminals for the External Wiring in the Converter .............................. 5-2

5.1.2 Wiring ...................................................................................................... 5-3

5.1.3 Mounting of Cable Gland........................................................................ 5-4

5.2 Wiring for Detector Output............................................................................. 5-5

5.2.1 Cable Specifications ................................................................................ 5-5

5.2.2 Connection to the Detector...................................................................... 5-6

5.2.3 Connection to the Converter ................................................................... 5-7