Toc-1

IM 11M12A01-04E

<CONTENTS>

Model ZR202G

Integrated type Zirconia Oxygen Analyzer

CONTENTS

IM 11M12A01-04E 7th Edition

Introduction ..............................................................................................................i

For the safe use of this equipment.............................................................................. iii

NOTICE ........................................................................................................................... vi

After-Sales Warranty .................................................................................................... vii

1. Overview.................................................................................................... 1-1

1.1 <EXAxtZR>SystemConguration............................................................... 1-1

1.1.1 System 1 ............................................................................................ 1-1

1.1.2 System 2 ............................................................................................ 1-2

1.1.3 System 3 ............................................................................................ 1-3

1.2 < EXAxt ZR > System Components ................................................................ 1-4

1.2.1 System Components ......................................................................... 1-4

1.2.2 Oxygen Analyzer and Accessories ....................................................1-4

2. Specications ........................................................................................... 2-1

2.1 GeneralSpecications..................................................................................... 2-1

2.1.1 StandardSpecications..................................................................... 2-1

2.1.2 ZR202G Integrated type Zirconia Oxygen Analyzer..........................2-2

2.1.3 ZO21R Probe Protector .....................................................................2-9

2.2 ZA8F Flow Setting Unit and ZR20H Automatic Calibration Unit................ 2-10

2.2.1 ZA8F Flow Setting Unit....................................................................2-10

2.2.2 ZR20H Automatic Calibration Unit...................................................2-12

2.3 ZO21S Standard Gas Unit .............................................................................. 2-14

2.4 Other Equipment.............................................................................................2-15

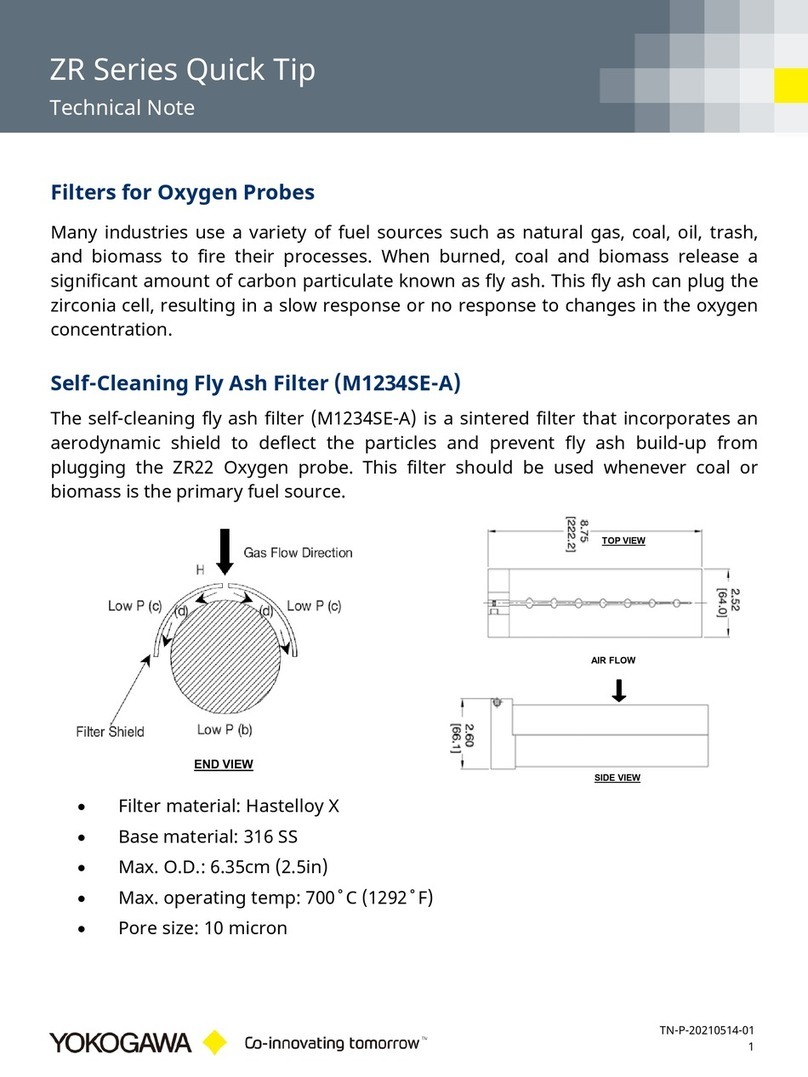

2.4.1 Dust Filter for Oxygen Analyzer (part no. K9471UA).......................2-15

2.4.2 Dust Guard Protector (part no. K9471UC) ......................................2-15

2.4.3 Stop Valve (part no. L9852CB or G7016XH)...................................2-16

2.4.4 Check Valve (part no. K9292DN or K9292DS)................................2-16

2.4.5 Air Set............................................................................................... 2-17

2.4.6 Zero Gas Cylinder (part no. G7001ZC) ........................................... 2-18

2.4.7 Pressure Regulator (G7013XF or G7014XF) for Gas Cylinder....... 2-18

2.4.8 Case Assembly (E7044KF) for Calibration gas Cylinder................. 2-19

2.4.9 ZR202A Heater Assembly ...............................................................2-19