Content

1 General information ........................................................ 3

1.1 Importance of the service manual for quick check of the bolted connections of the worm

wheel .............................................................. 4

1.2 Target group ......................................................... 4

1.3 xclusion of liability ................................................... 4

1.4 Copyright ........................................................... 4

2 Safety instructions ......................................................... 5

2.1 Pictographs ......................................................... 5

2.2 Requirements placed on the personnel / due diligence ........................ 5

2.3 General safety instructions .............................................. 5

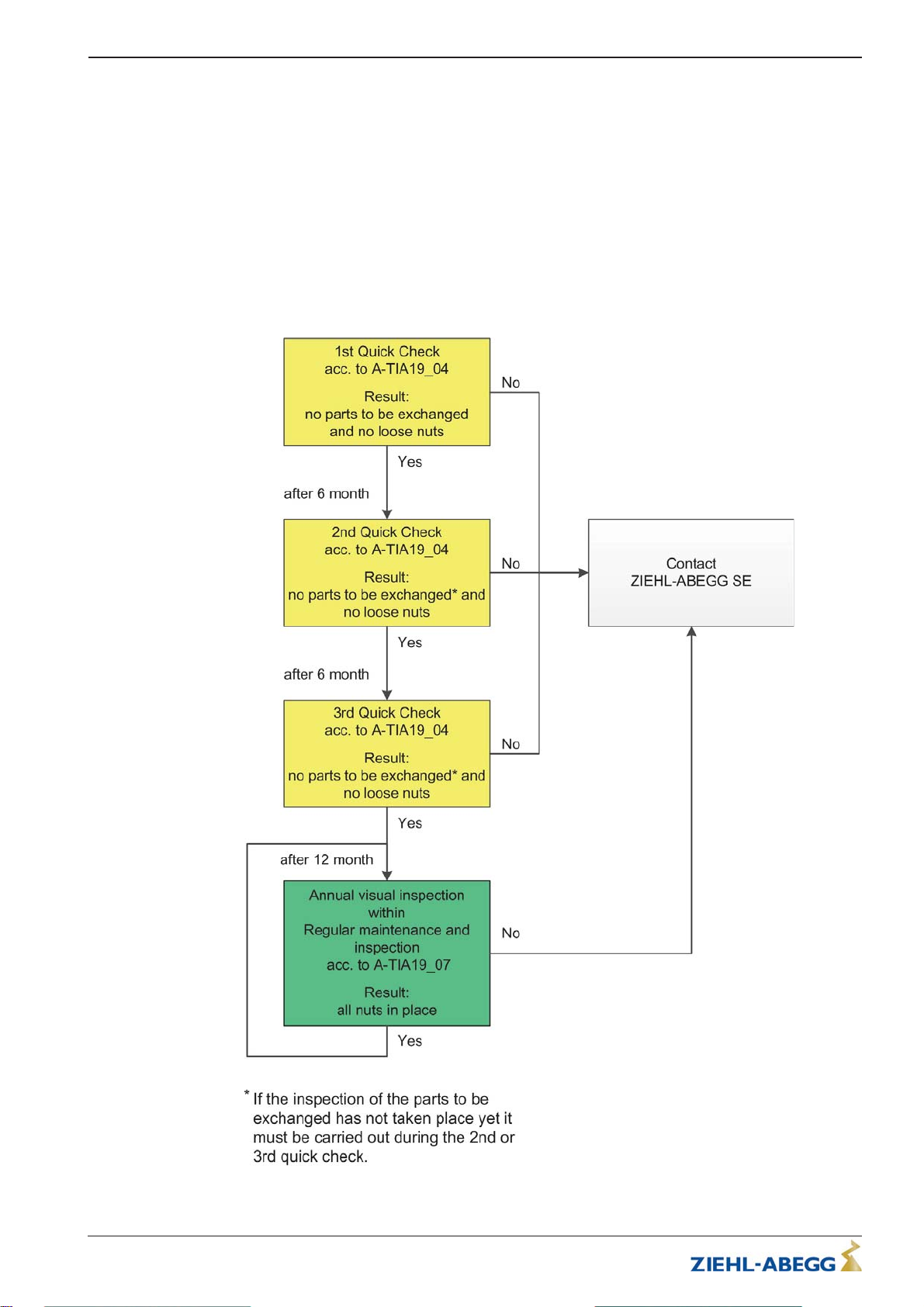

3 Quick Check .............................................................. 6

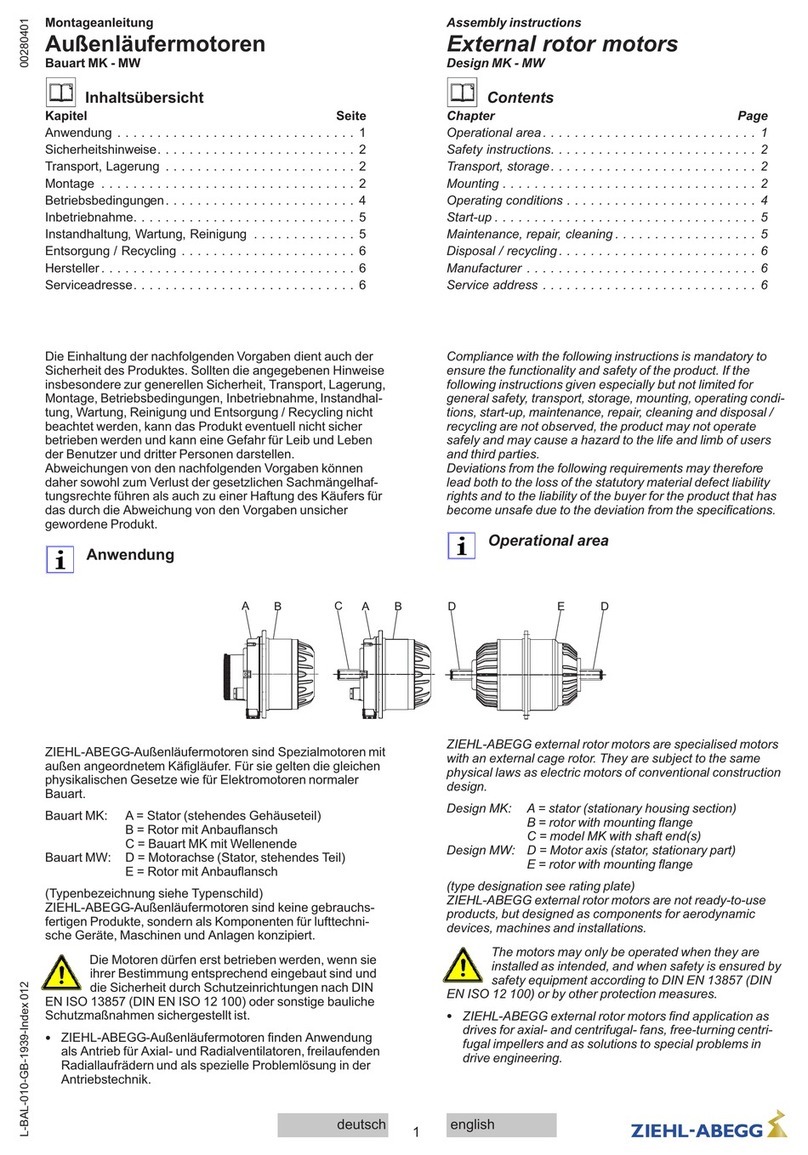

3.1 Operational area ...................................................... 6

3.2 Requirements for the quick check ........................................ 6

3.3 Target of the quick check: .............................................. 6

3.4 General Preliminary Clarification: ......................................... 6

3.5 Specific Preliminary Clarification: ......................................... 7

3.6 Required tools ....................................................... 7

4 Quick Check of the bolted connection of the orm heel ......................... 8

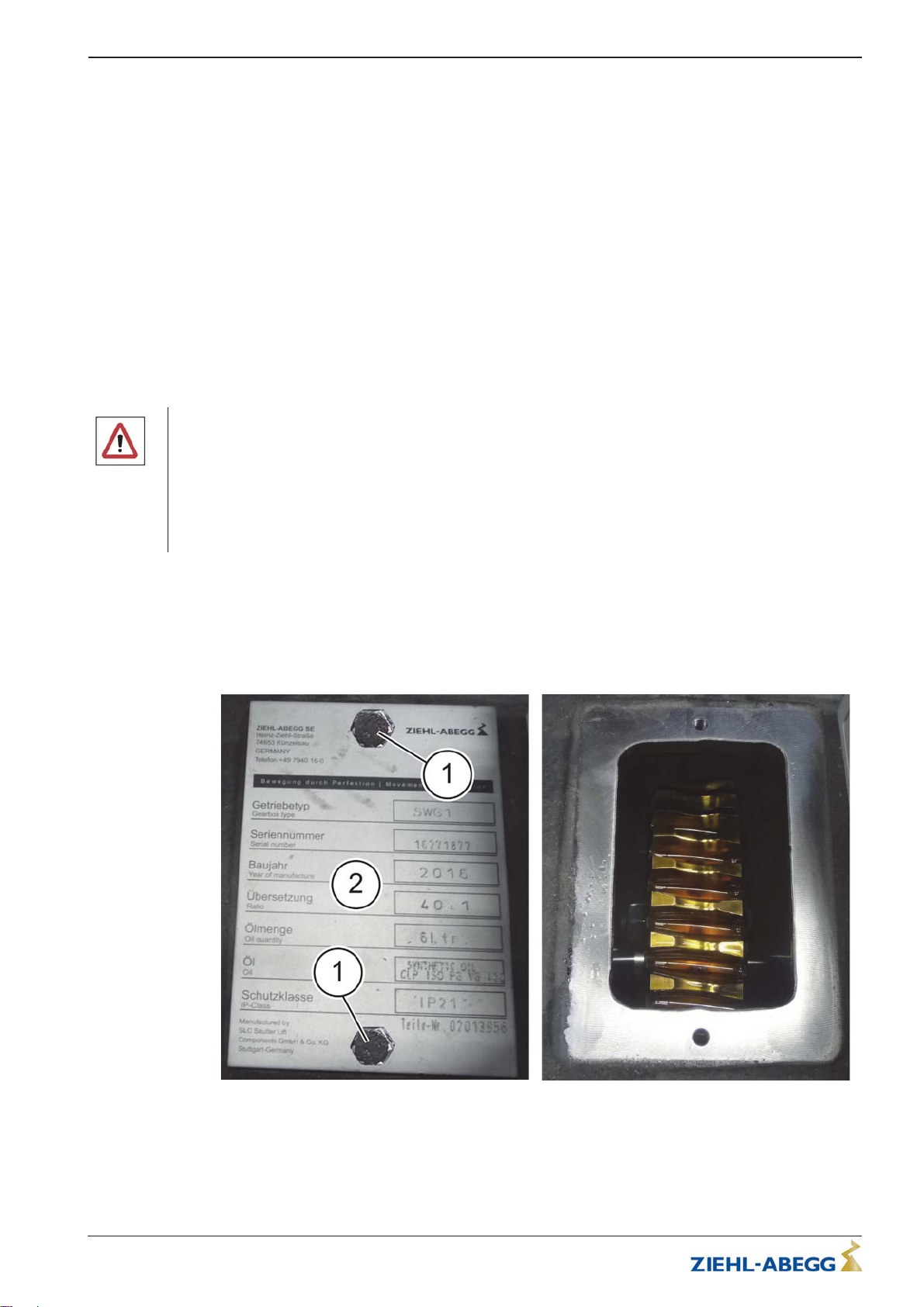

4.1 Removing the name plate / Opening the maintenance hole ..................... 8

4.2 Positioning of the worm wheel ........................................... 9

4.3 Optical appraisal of the fitting bolts ........................................ 9

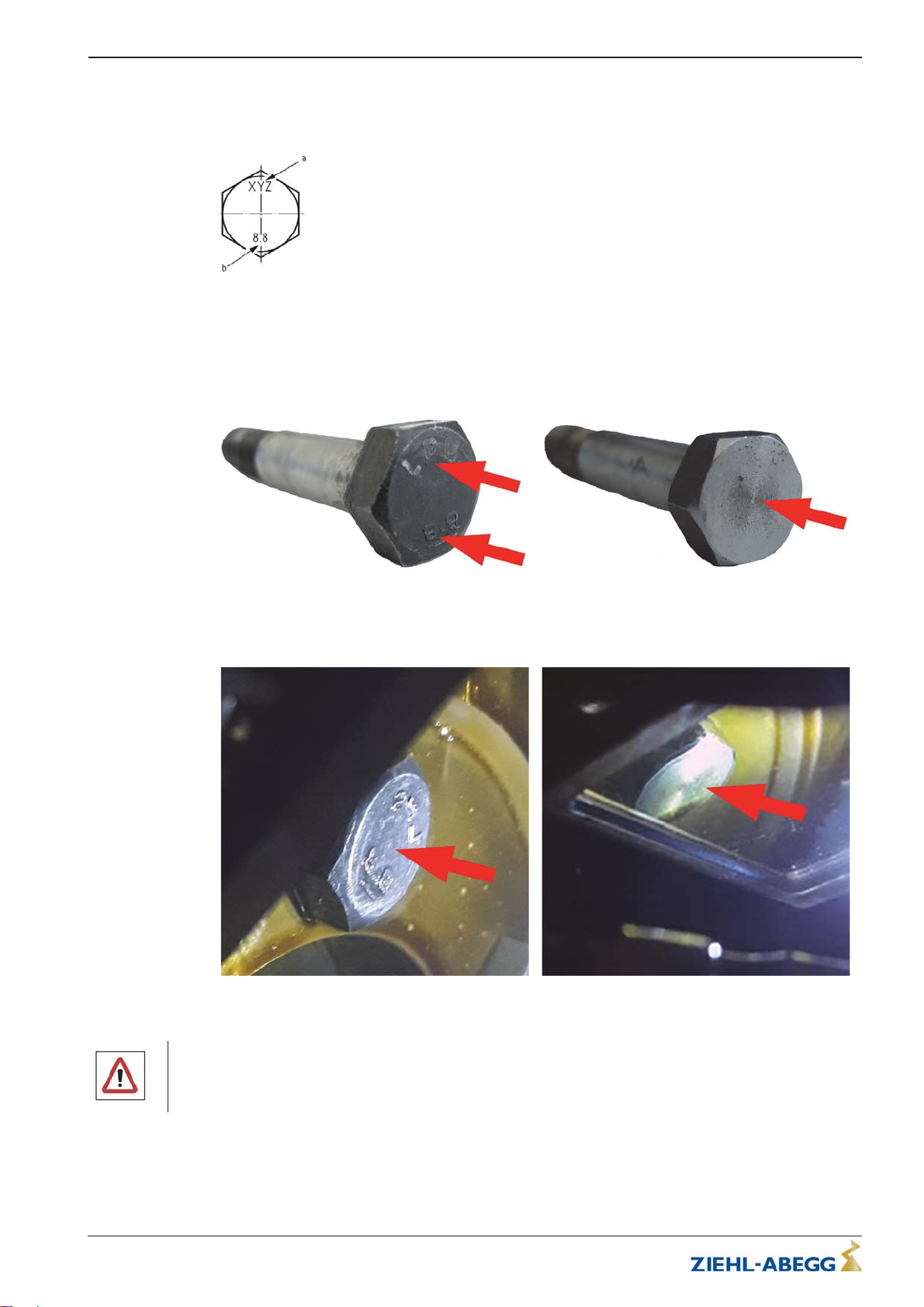

4.3.1 Identification of the fitting bolts ...................................... 10

4.3.2 Inspection of the length of the fitting bolts .............................. 11

4.4 Visual inspection of the screw locking device ................................ 11

4.4.1 Checking the size of the tooth lock washer ............................. 12

4.4.2 Checking for spring washer ........................................ 13

4.5 Correct execution of the bolted connection ................................. 14

4.6 Inspection of tightening ................................................. 14

4.6.1 Optical appraisal of the nuts ....................................... 15

4.6.2 Inspection of tightening with suitable spanner ............................ 15

4.7 Documentation of the inspection results .................................... 16

5 Enclosure ................................................................ 17

5.1 Drawing for special spanner for ZAS2 with transmission ratio 27:1 and 27:2 and ZAS3

17

5.2 Test protocol 1 ....................................................... 18

5.3 Test protocol 2 ....................................................... 21

5.4 Report to the company ZI HL-AB GG S ................................. 23

Service instructions ZAS0, ZAS1, ZAS2, ZAS3

A-TIA19_04-GB 1933 Index 006 Part.-No. 01013454-GB

2/24