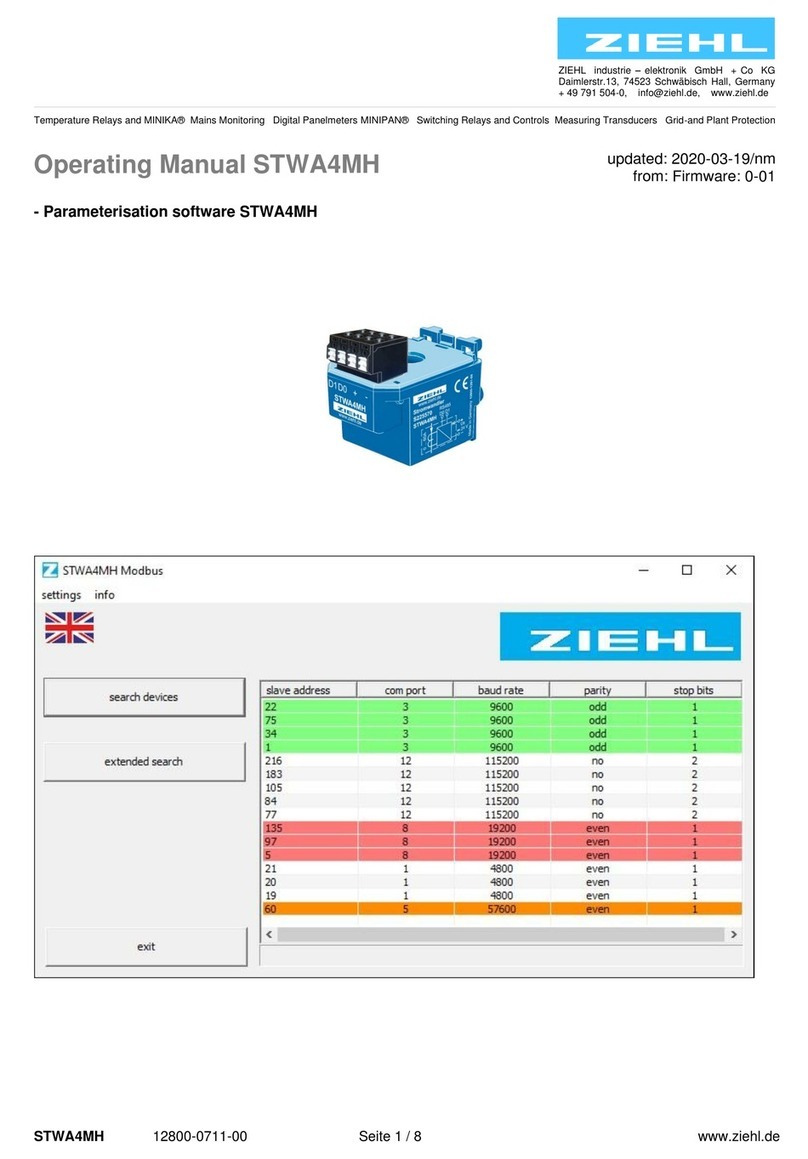

Table of contents

1 General Notes......................................................................................................................................3

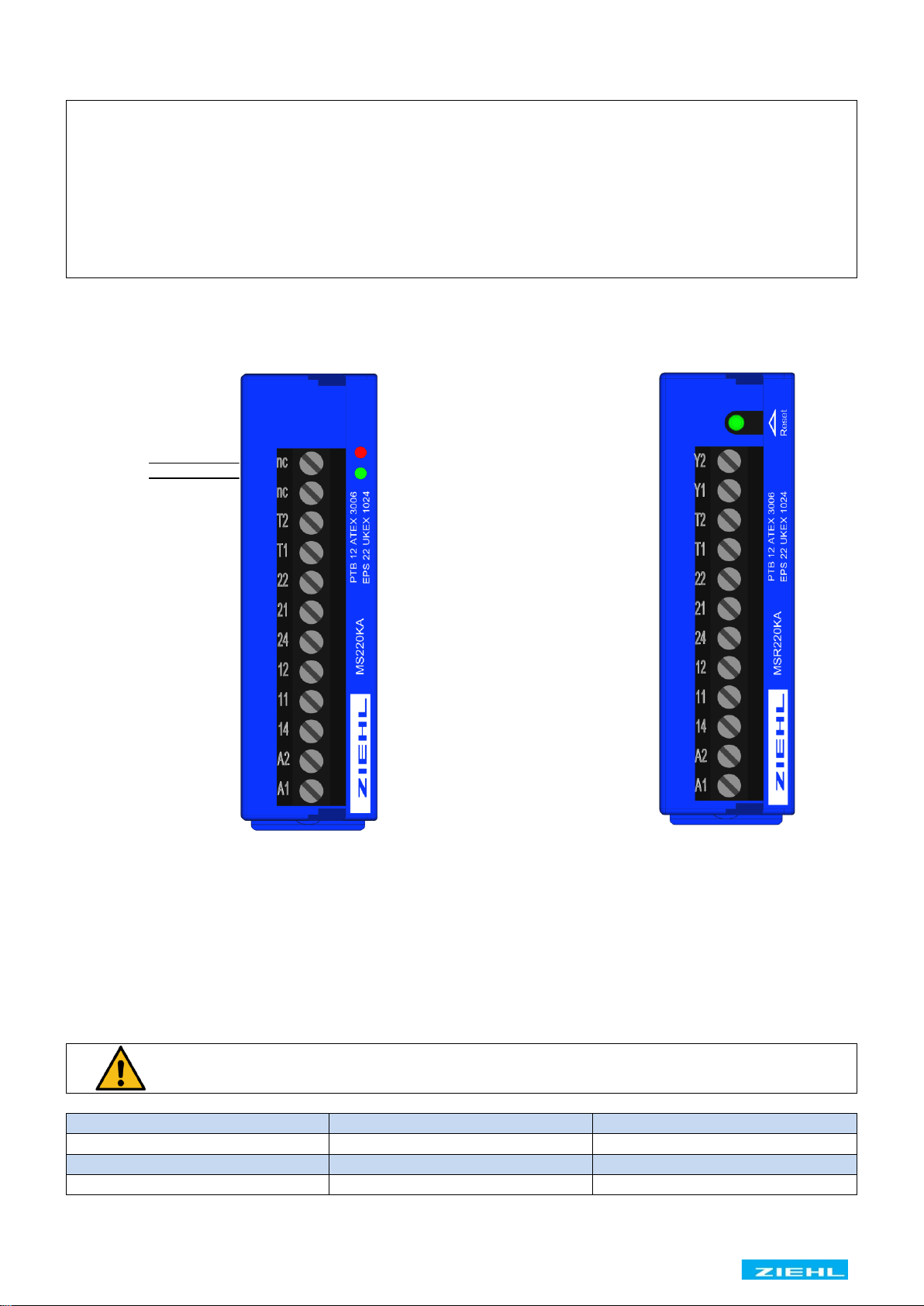

2 Display- and control elements............................................................................................................3

3 Pre-Adjustment....................................................................................................................................3

4 Application and brief description.......................................................................................................4

5 Summary of features...........................................................................................................................4

6 Connecting diagram............................................................................................................................4

7 Function diagram ................................................................................................................................5

8 Important notes ...................................................................................................................................5

9 Installation ...........................................................................................................................................5

10 Commissioning..................................................................................................................................6

11 Operating instructions......................................................................................................................6

12 Troubleshooting and remedies ........................................................................................................6

13 Technical data ...................................................................................................................................6

14 Dimensions - Design K......................................................................................................................8

15 Safety instructions and references for putting into operation.......................................................8

15.1 Explosive atmospheres..............................................................................................................8

15.2 Special remarks for explosive gas atmospheres areas (Zone 0, 1 and 2) ..................................8

15.3 Special remarks for use in the presence of combustible dust (Zone 20, 21, and 22)..................8

15.4 Safety characteristics of the safety device (EN 50495 / VDE 0170-18)......................................9

15.5 Category and Performance-Level (EN ISO 13849-1).................................................................9

15.6 Application of the safety device used with equipment category (EN 50495 / VDE 0170-18).......9

15.7 Wiring........................................................................................................................................9

15.8 Safe separation........................................................................................................................10

15.9 Stop function............................................................................................................................10

15.10 Start and restart.....................................................................................................................10

15.11 Manual reset..........................................................................................................................10

16 Proof testing of the safety functions..............................................................................................10

17 Maintenance and repair...................................................................................................................11

18 Disposal ...........................................................................................................................................11

19 EU / UK -Declaration of Conformity................................................................................................12