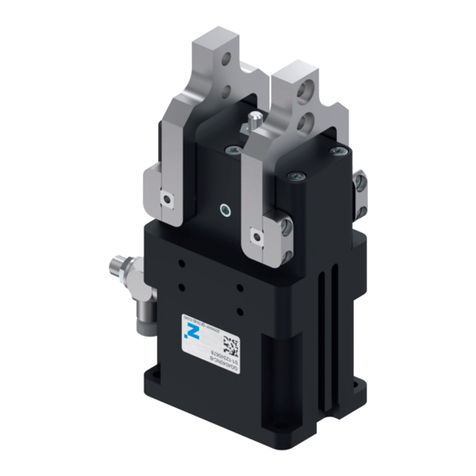

INSTALLATION AND OPERATING INSTRUCTIONS: 2-jaw parallel gripper, electric, GEH8000 series

3

DDOC00262 / a EN / 5/7/2019

Zimmer GmbH ●Im Salmenkopf 5 ●D-77866 Rheinau, Germany ●+49 7844 9138 0 ● +49 7844 9138 80 ●www.zimmer-group.com

1 Supporting documents

NOTICE:

Read through the installation and operating instructions carefully before installing the product!

The installation and operating instructions contain important notes for your personal safety. They

must be read and understood by all persons who work with or handle the product during any phase

of the product life time.

The documents listed below are available for download on our website.

Öwww.zimmer-group.com

Only those documents currently available on the website are valid.

• Catalogs, drawings, CAD data, performance data

• Information on accessories

• Detailed installation and operating instructions

• Technical data sheets

• General Terms and Conditions of Business, including warranty information

2 Safety notices

CAUTION:

Non-compliance may result in severe injuries!

1. Installation,commissioning,maintenanceandrepairsmayonlybeperformedbyqualiedexpertsinaccor-

dance with the installation and operating instructions.

2. The gripper is state-of-the-art. It is installed on industrial machines and is used to hold workpieces. The follow-

ingareexamplesofsituationsinwhichthegrippermaycauseahazard:

• The gripper is not properly installed, used or maintained.

• The gripper is not used for its intended purpose.

• Local regulations (legislation, ordinances, guidelines), such as the EC Machinery Directive, accident pre-

vention regulations and the installation and operating instructions, are not observed.

3. The gripper may be used only in accordance with its proper use and technical data. Zimmer GmbH shall ac-

cept no liability for any damage caused by improper use.

4. Any use other than the intended use requires written approval from Zimmer GmbH.

5. Do not reach into the operational range of the gripper.

6. Make sure that the power cables are disconnected before you install, modify, maintain or repair the gripper.

7. Incaseofmaintenance,conversionorexpansionwork,removethegripperfromthemachineandperformthe

work outside the danger zone.

8. When commissioning or testing, make sure that the gripper cannot be actuated by mistake.

9. Grippermodications,suchasaddingdrilledholesorthreads,maybemadeonlywithpriorapprovalfrom

Zimmer GmbH.

10.Thespeciedmaintenanceintervalsaretobeobserved;alsorefertothe“Maintenance”section.Pleasecon-

tact our Service hotline for this purpose.

11.Useofthegripperunderextremeconditions,suchasaggressiveliquidsandabrasivedusts,issubjecttoprior

approval from Zimmer GmbH.