Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau ● Germany ●+49 7844 9138 0 ● +49 7844 9138 80 ● www.zimmer-group.com

INSTALLATION AND OPERATING INSTRUCTIONS: Axis compensation module, pneumatic, XYR series

Installation and Im Salmenkopf 5

operating

instructions 77866 Rheinau

XYR series Germany

DDOC00257 +49 7844 9138 0

EN 2022-01-10 www.zimmer-group.com

1. Supporting documents

NOTICE

Read through the installation and operating instructions before installing or working with the product.

The installation and operating instructions contain important notes for your personal safety. They must be read and

understood by all persons who work with or handle the product during any phase of the product lifetime.

The documents listed below are available for download on our website www.zimmer-group.com:

• Catalogs, drawings, CAD data, performance data

• Information on accessories

• Detailed installation and operating instructions

• Technical data sheets

• General Terms and Conditions with specications for the warranty entitlement

ÖOnly those documents currently available on the website are valid.

In these installation and operating instructions, "product" refers to the product designation on the title page.

2. Safety notices

CAUTION

Risk of injury and material damage in case of non-compliance

Installation, commissioning, maintenance and repairs may only be performed by qualied specialists in accordance

with these installation and operating instructions.

The product is state-of-the-art. It is tted to industrial machines and is used to compensate axial deviations.

The following are examples of situations in which the product may cause a hazard:

• The product is not properly installed, used or maintained.

• The product is not used for its designated purpose.

• The locally applicable regulations, laws, directives or guidelines are not observed.

The product may only be used in accordance with these installation and operating instructions and the product's

technical data. Any changes or additions to the intended use of the product, as well as modications to the product,

such as those in the following examples, require the written permission of the manufacturer:

• Use of the product under extreme conditions, such as aggressive uids or abrasive dusts

• Additional drilled holes or threads

ÖZimmer GmbH shall accept no liability for any damage caused by improper use. The operator bears sole responsi-

bility.

Installation, commissioning, maintenance and repairs may only be performed by qualied specialists in accordance

with these installation and operating instructions.

►Make sure that the power supply is disconnected before you mount, adjust, modify, maintain or repair the product.

►When the product is used under extreme conditions, the maintenance interval must be adapted depending on the

extent of the contamination.

3. Proper use

NOTICE

The product is only to be used in its original state with its original accessories, with no unauthorized changes and

within the stipulated parameter limits and operating conditions. Any other or secondary use is deemed improper.

►Operate the product only in compliance with the associated installation and operating instructions.

►Operate the product only when it is in a technical condition that corresponds to the guaranteed parameters and

operating conditions.

ÖZimmer GmbH shall accept no liability for any damage caused by improper use. The operator bears sole responsi-

bility.

The product is designed exclusively for pneumatic operation using a maximum operating pressure of 8bar.

It is not suited for operation with other media such as liquids or gases.

The product is designated for use in closed facilities.

Direct contact with perishable goods/food is not permitted.

4. Personnel qualication

Installation, commissioning and maintenance may only be performed by trained specialists. These persons must have read and

understood the installation and operating instructions in full.

5. Product description

5.1 Forces and torques

INFORMATION

For information on the forces and torques for this product, please refer to our website

www.zimmer-group.com.

Please contact Zimmer Customer Service if you have any questions.

5.2 Type plate

A type plate is attached to the housing of the product.

The article numberam and conrmation numberan are shown on the type plate. XXX

XX-XXXXXX

am

an

6. Function

Using adjustment screws, the properties of the product can be optimally adapted to your application in a very short time. The

at structure reduces the moment load for the robot to a minimum and makes it possible to use smaller and more affordable

installation sizes. Depending on requirements, the compensation module can be positioned and xed centrally or off-center.

Depending on requirements, you can either clamp or centrally lock the module. This is an aid for an optimal process.

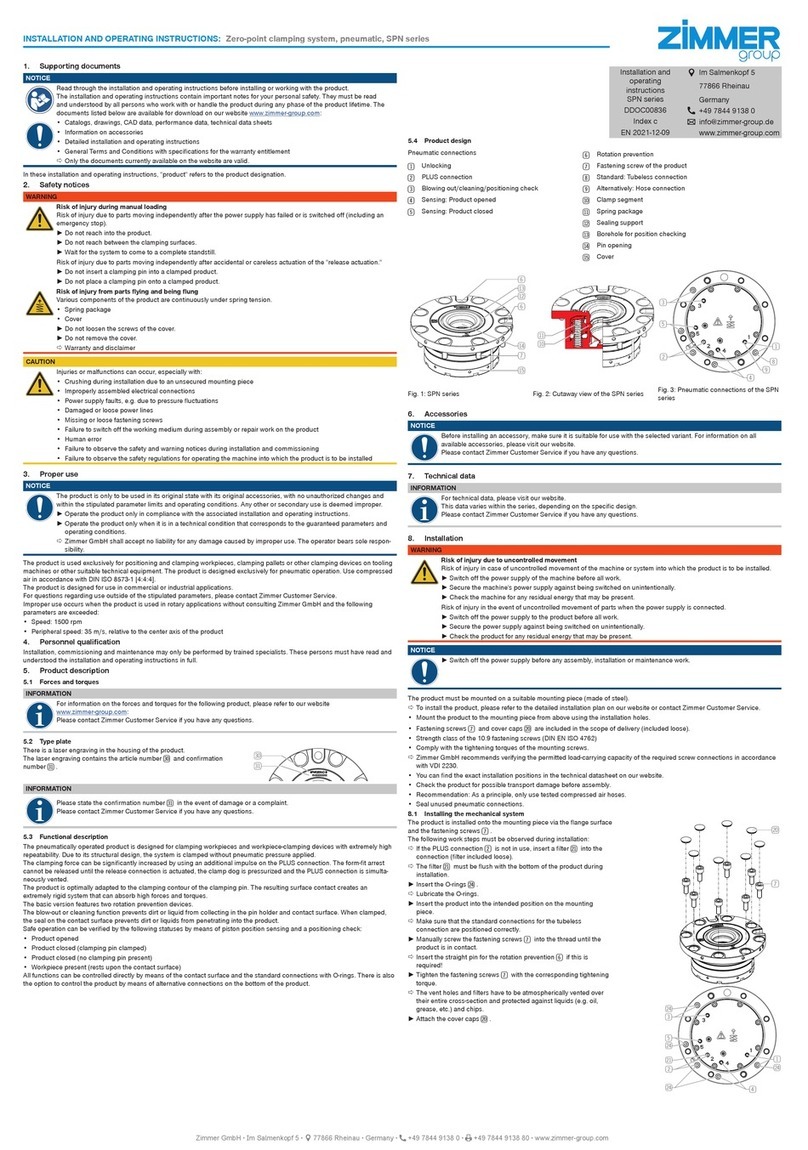

1Mounting screws

1

2

3

5

4

bl

1

3

5

6

7

2

bl

2Locking piston sensing (optional)

3Eccentric clamp sensing (optional)

4Compensation range

5Compensation force

6Linear guide

7Compensation plates

8Locking piston

9Eccentric clamp

bl Piston position sensing (optional)

bm Straight pin (not included in the scope of

delivery)

7. Installation

7.1 General installation information

WARNING

Risk of injury due to uncontrolled movement

Risk of injury in case of uncontrolled movement of the machine or system into which the product is to be installed.

►Switch off the power supply of the machine before all work.

►Secure the machine's power supply against being switched on unintentionally.

►Check the machine for any residual energy that may be present.

CAUTION

Risk of injury due to uncontrolled movement

Risk of injury in the event of uncontrolled movement of the product when the power supply is connected.

►Switch off the power supply to the product before all work.

►Secure the power supply against being switched on unintentionally.

►Check the product for any residual energy that may be present.

NOTICE

►Switch off the power supply before any assembly, installation or maintenance work.

The product must be installed on a suitable mounting surface in accordance with the atness specications.

ÖPermissible unevenness: 0.03 mm

• The tool-side fastening screws and straight pin are not included in the scope of delivery.

• Strength class of the mounting screws: ≥ 8.8 (DIN EN ISO 4762)

• Observe the tightening torque of the mounting screws.

ÖZimmer GmbH recommends verifying the permitted load-carrying capacity of the required screw connections in accordance

with VDI 2230.

• The exact installation positions can be found on the technical data sheet on our website.

7.2 Installing the mechanical system

The following work steps must be observed during

installation:

►Insert a straight pinbm (not included in the

scope of delivery) into the designated hole.

►Position the product on the robot using the

straight pinbm.

►Use the mounting screws1to secure the

product on the robot.

ÖTo tighten the mounting screws, you can use

the threaded holes on the underside.

7.3 Installing the sensor system

Mounting blocks for sensing are included in the

scope of delivery.

The following work steps must be observed during

conguration:

Locking piston sensing 2

• Switch cams extended.

• Locking piston active.

Eccentric clamp sensing 3

• Switch cams extended.

• Eccentric clamp active.

• Locking piston in initial position

1

2

3

7.4 Installing the power supply

The following work steps must be observed during

installation:

►Place the pneumatic ttingsbn lightly.

►Align the pneumatic ttings.

►Tighten the mounting screws with the

corresponding tightening torque.

The gure below and the status plot show an

example diagram of the pneumatic power supply.

bn

AB

1.0

b

a0

Valve Status Locking piston locked Locking piston unlocked Eccentric clamp active Eccentric clamp

deactivated

1.0

a

0

b

7.5 Installing accessories

NOTICE

Before installing an accessory, make sure it is suitable for use with the selected variant.

For information about the complete range of accessories, refer to our website at www.zimmer-group.com.

Please contact Zimmer Customer Service if you have any questions.