7

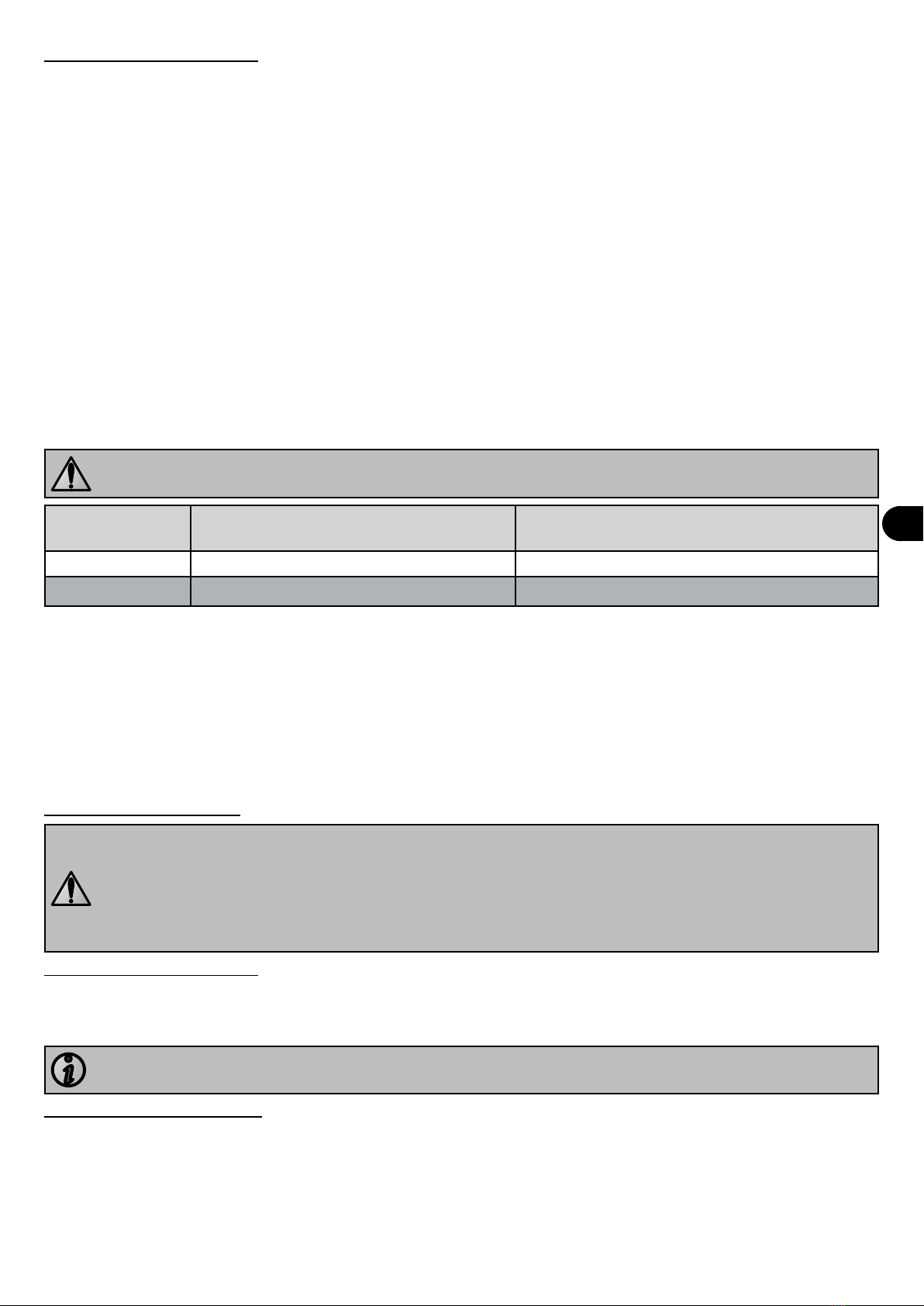

5. Troubleshoong

5.1 Error codes

Number of

ashes Malfuncon Possible causes Soluons

1User interface is

defecve • The user interface resets itself

constantly • Check the electrical connecons inside

the user interface housing.

• Replace the motor - interface assembly

if necessary.

2Network sub-

voltage • The network voltage has fallen

below 180VCA. • The interface will reset when the

voltage rises over 209VCA again for at

least 6 seconds

3Temperature • Motor temperature too high

(+100°C)

• Motor temperature too low

(-20°C)

• Wait unl normal temperature condions

return and restart the pump.

4 Surge acvaon • The surge protecon has been

acvated • Check the electrical supply.

• Restart the pump.

5Network

overvoltage • The voltage exceeds 269VCA • The interface will reset when the

voltage returns to a normal value.

6Motor sha jammed • Motor start-up impossible

• The motor has stopped • Break the pump circuit and check

that no debris is blocking the turbine

(remove the pre-lter screen).

• Check that there is no debris blocking

the rear fan.

7Automac

vericaon • At least one of the automac

tests failed on start-up or

during operaon

• Break the pump circuit then reconnect it

to reset it.

8 Motor fault • At least one of the phases is

disconnected • Check the electrical connecons inside

the user interface housing.

5.2 Equipment malfuncon

Malfuncon Possible causes Soluons

The water does not

circulate correctly • Pre-lter screen and/or lter

blocked with dirt

• Valves incorrectly set

• Clean the pre-lter screen and/or the lter

• Set the valves

Air bubbles are present

in the pre-lter screen • Air blocked in the circuit

• Swimming pool water level too

low

• Incorrect pre-lter cover seal

• Bleed the circuit

• Check the water level and top up if necessary

• Check that the cover and its seal are water-ght

There are air intakes • Couplings incorrectly ghtened

• Coupling seals incorrectly

posioned or damaged

• Reghten the couplings

• Change the seals

There is no air in the

circuit but the pressure

is low

• Debris jammed in the pump • Remove the debris by hand by opening the cover and

removing the pre-lter screen

• If debris remains, you must dismantle the pump to

access the turbine

• Cauon: these tasks must be carried out by a qualied

technician

There is no debris in the

pump but the pressure

is low

• The turbine and the pump

diuser are worn

• Electrical problem

• Seal worn

• Have the turbine and the diuser replaced by a

qualied technician

• Have the electrical installaon checked by a qualied

technician

• Replace the seal

There is a water leak

between the motor and

the pump body

• Mechanical lining damaged or

defecve • Replace the mechanical lining

• Cauon: these tasks must be carried out by a qualied

technician

The pump heats up and

switches o somemes • Poor air circulaon around the

motor

• Poor electrical connecons

• Current variaons too high

• Check that the motor is venlated enough to cool

down

• Check the electrical connecons

• Have the electrical network checked by a qualied

technician

The pump does not

start • No electrical supply to the pump

• The user interface cable is

damaged

• The "error" light ashes

• Check the electrical connecons

• Check the condion of the user interface cable

• See § “5.1 Error codes”

There is no damage to

the user interface • Cables damaged or poorly

connected in the user interface

housing

• Check the condion of the user interface cables