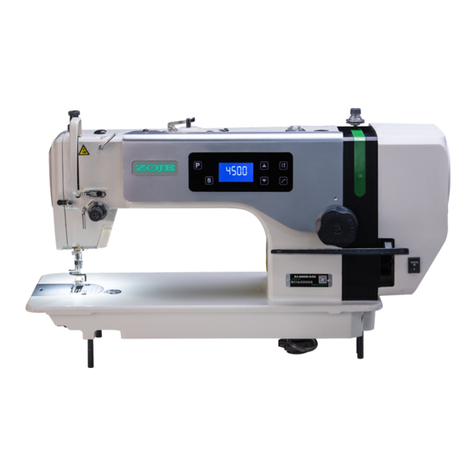

ZOJE ZJ9800 User manual

Other ZOJE Sewing Machine manuals

ZOJE

ZOJE A6000-G User manual

ZOJE

ZOJE ZJ2628 User manual

ZOJE

ZOJE A9200L-D4S-W-CP-Z User manual

ZOJE

ZOJE ZJ24028-1 User manual

ZOJE

ZOJE ZJ20U Series User manual

ZOJE

ZOJE ZJ-M3-S500-SF-V2 User manual

ZOJE

ZOJE ZJ-M3-S350-SF User manual

ZOJE

ZOJE ZJ2628-1 User manual

ZOJE

ZOJE 5780BS User manual

ZOJE

ZOJE ZJ9800 User manual

ZOJE

ZOJE ZJ5300 User manual

ZOJE

ZOJE ZJ-E007 User manual

ZOJE

ZOJE ZJ9700 User manual

ZOJE

ZOJE ZJW662 User manual

ZOJE

ZOJE QD2622 Series User manual

ZOJE

ZOJE ZJ5820 User manual

ZOJE

ZOJE ZJ1900DSS-3-04-V4-TP User manual

ZOJE

ZOJE ZJ1414 User manual

ZOJE

ZOJE ZJ-M3-S500-SF-V2 User manual

ZOJE

ZOJE ZN90 User manual