Zonestar Z5 Series User manual

Other Zonestar 3D Printer manuals

Zonestar

Zonestar P802CR2 User manual

Zonestar

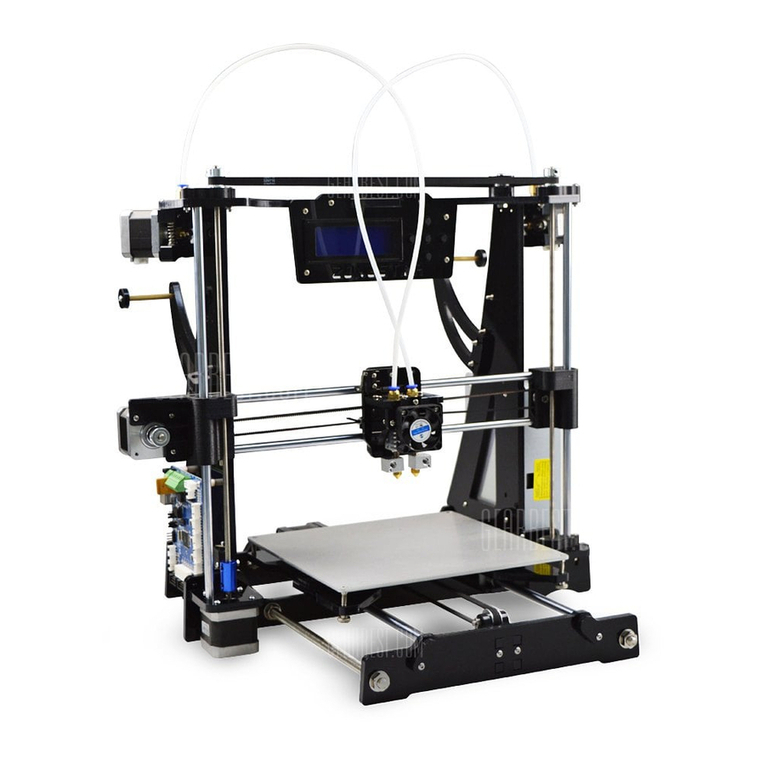

Zonestar P802-STS User manual

Zonestar

Zonestar Z9 Series User manual

Zonestar

Zonestar Z8X User manual

Zonestar

Zonestar Z6 User manual

Zonestar

Zonestar P802QS User manual

Zonestar

Zonestar P802QS User manual

Zonestar

Zonestar P802QS User manual

Zonestar

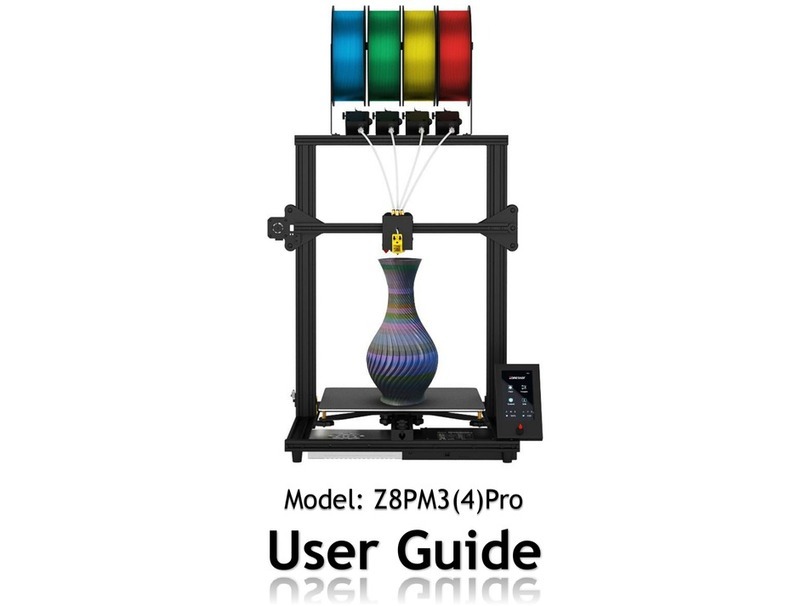

Zonestar Z8PM4 Pro User manual