Prepare to print - Load Filament

11

Preheat nozzle: Choose “Prepare”>> “Preheat PLA”, then nozzle and hotbed will be heated.

Waiting nozzle temperature reached to setting.

If there is filament in the hotend, do this step, otherwise skip this step.

Choose “Prepare”>> “Move axis”>>”Extruder”>>”Move 1mm”>>”extruder: ****mm”, then

Clockwise rotate the knob slowly, until you can see the filament flow from the nozzle.

1

2

3 If there is filament in the hotend, do this step, otherwise skip this step.

Press the handle on the extrude feeder and pull out the filament.

4 Press the handle on the extrude feeder and insert filament, make sure the filament has been

inserted to the hotend.

Choose “Prepare”>> “Move axis”>>”Extruder”>>”Move 1mm”>>”extruder: ****mm”, then

Clockwise rotate the knob slowly, until you can see the filament flow from the nozzle.

5

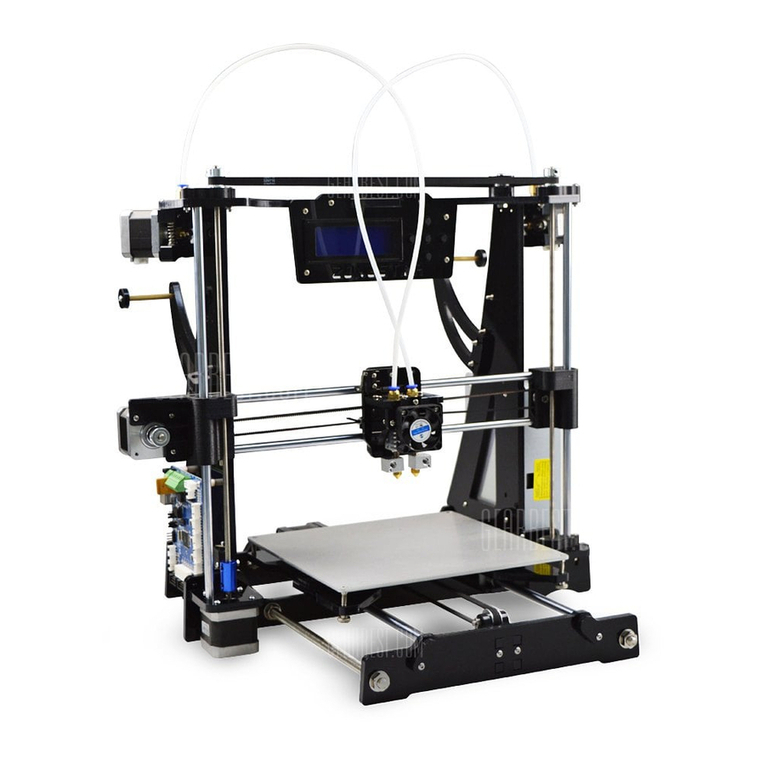

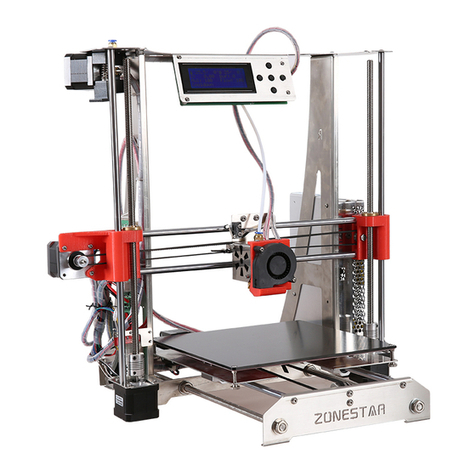

Use a diagonal pliers

to cut off the head of

filament

Press the handle and

insert filament into

the extruder engine

When loading filament, make sure it has entered the

hotend, if it clog in extruder or hotend, try to remove

the fittings and load the filament again.

Filament

NOTE

Extrude engine

PTFE tube

PTFE fitting

PTFE fitting

NOTE