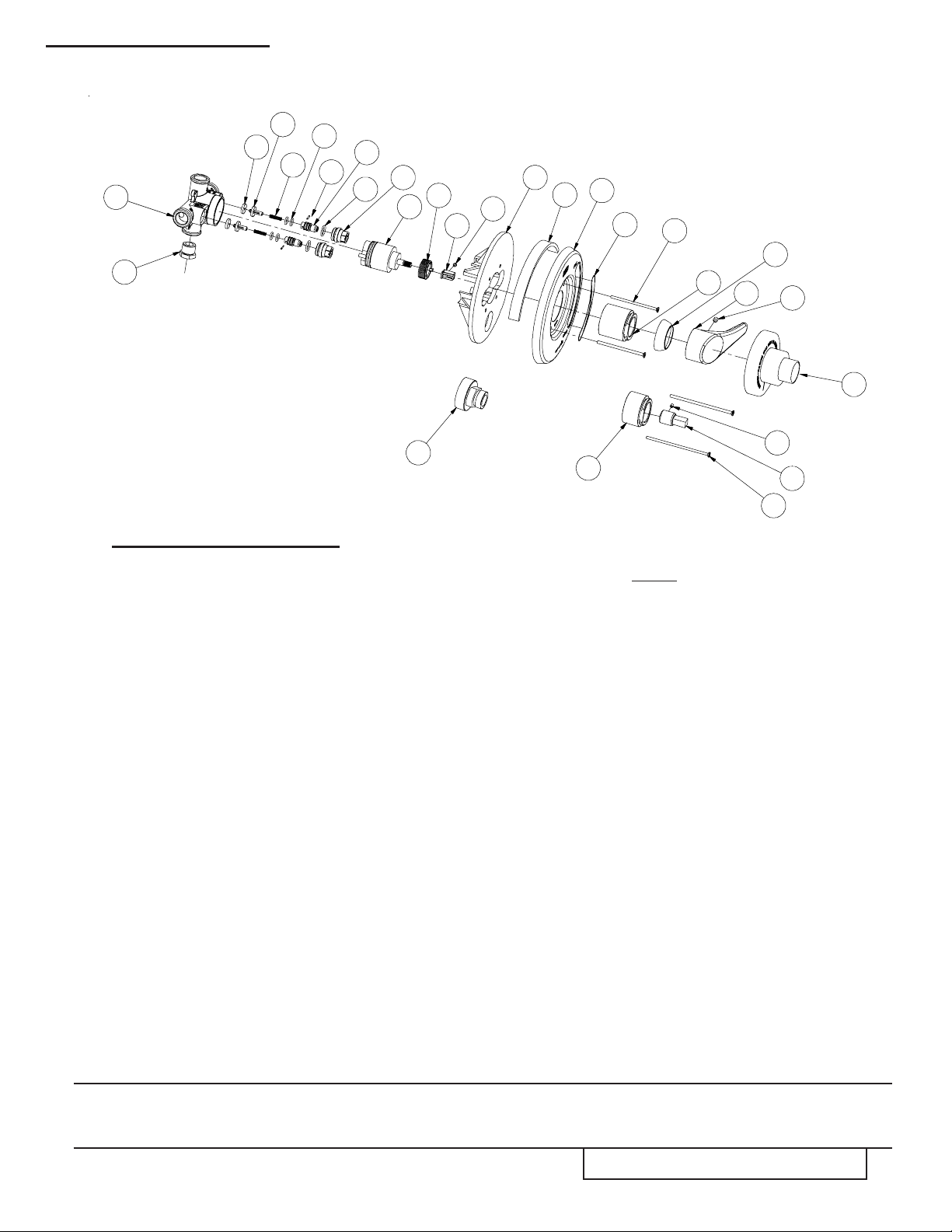

Operation

Installation

Maintenance Instructions

Replacement Kits

Pressure Balancing Shower/

Tub & Shower Valve

Z7300 Series

TEMP-GARD III

FOROPTIMUMVALVE PERFORMANCE, BALANCE SUPPLYPRESSURESTO LESS THAN 5 PSI PRESSURE

DIFFERENTIALBETWEENHOTANDCOLD WATERSUPPLIES.

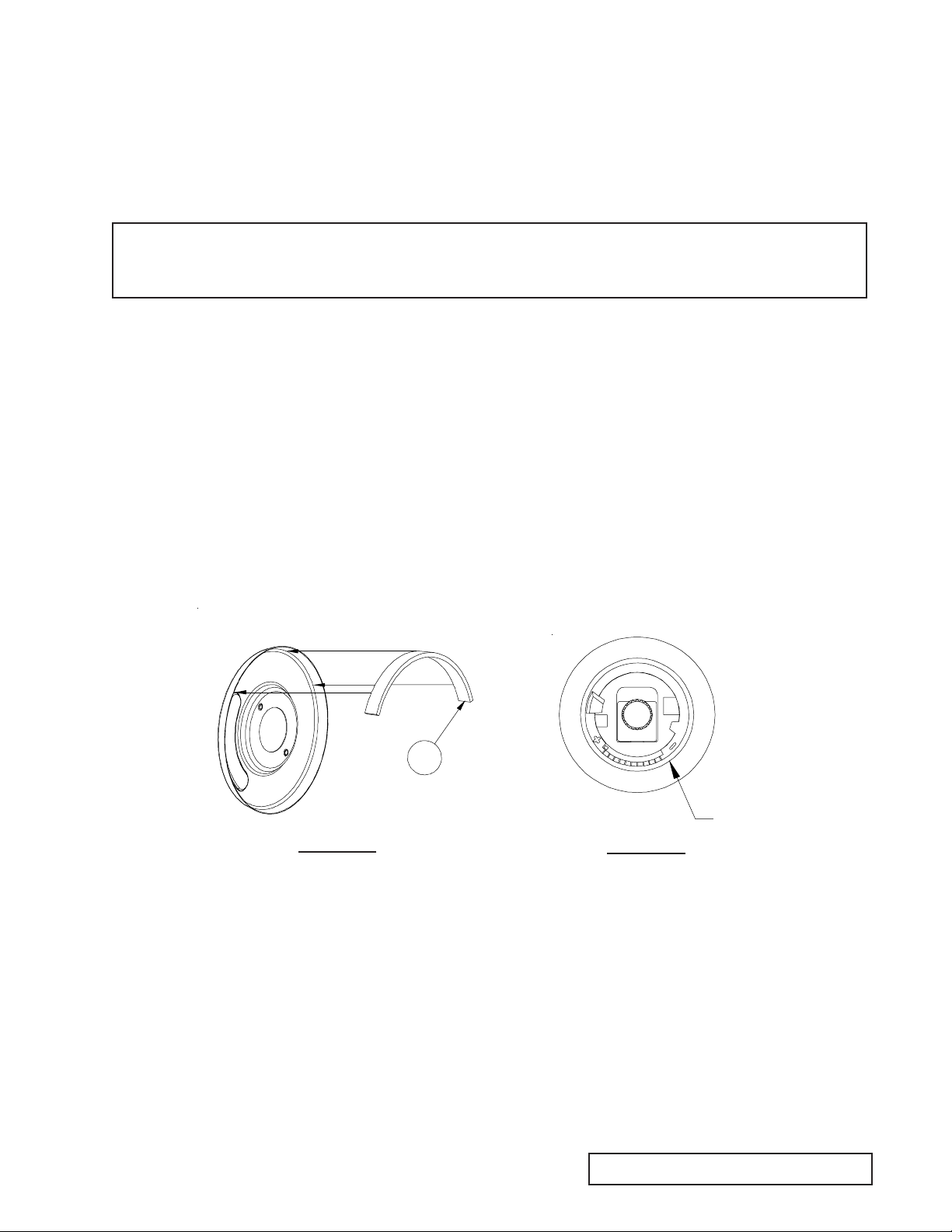

2. Always install valve with mud guard (23) so that the indicated surface on mud guard is flush with finished wall.

The hole in the wall should be 4” in diameter.

3. If valve is to be used for a shower only, wrap threads on tub plug (24) with teflon tape and install plug into tub

port on shower valve.

4. When the final outer wall is finished remove mud guard and open both supply stops on valve by turning

counter clockwise.

5. Loosen and remove escutcheon (19) from valve. Carefully remove cartridge (10) from valve by holding

cartridge as close to the valve body (1) as possible and wiggling back and forth until cartridge comes out of

the valve. Place thumb and finger on gray part of cartridge to remove it, as shown in Figure 4.

6. With the cartridges removed from all valves in the system, turn on water supply and flush the system of any

debris. If the water coming out of the valve while flushing is going behind finished wall, a hose bib flushing out

kit (RK7300-20HB) may be used to allow the water to be directed to a drain by attaching a garden hose to

valve.

7. If hot and cold supply inlets are reversed simply remove cartridge and reinstall with cartridge flipped

180o. The handle adaptor (12) will need to be readjusted. To adjust handle adaptor remove and turn

180o. Handleshould always turn through cold, then hot. Reinstall cartridge and tighten escutcheon to

150 in lbs. The system will need to be flushed again before installing shower heads.

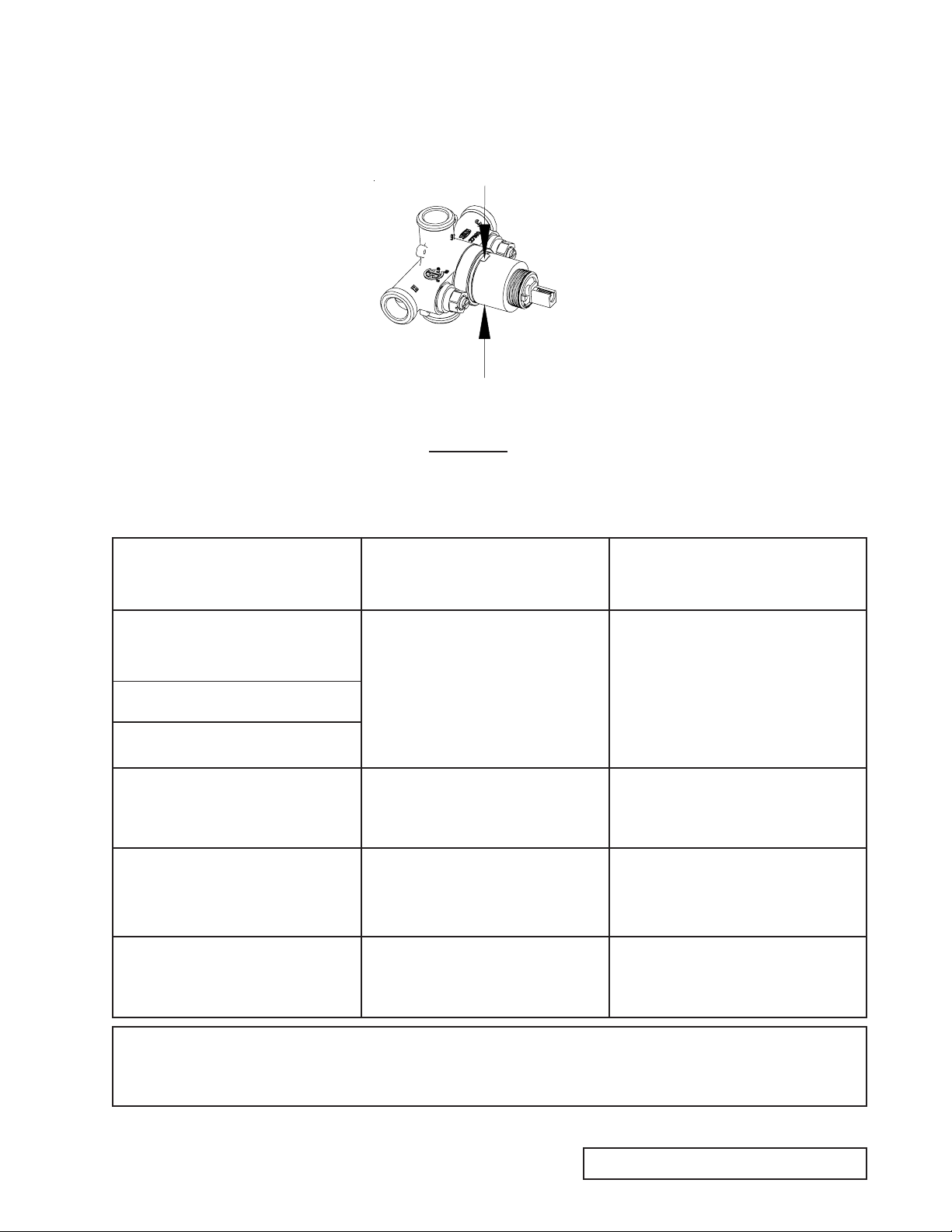

8. To adjust temperature limit stop (11), turn valve to desired hottest temperature, remove temperature

limit stop (11) turn clockwise and reinstall so that the white protrusion on cartridge is touching the red

protrusion on the temperature limit stop.

9. After all flushing is done install shower heads and check system for leaks.

INSTALLATION OF TEMP-GARD III SHOWER VALVE

(Refer to page 4 for part no.)

AquaSpec®is a registered trademark

of Zurn Industries, LLC

©2010 Zurn Industries, LLC

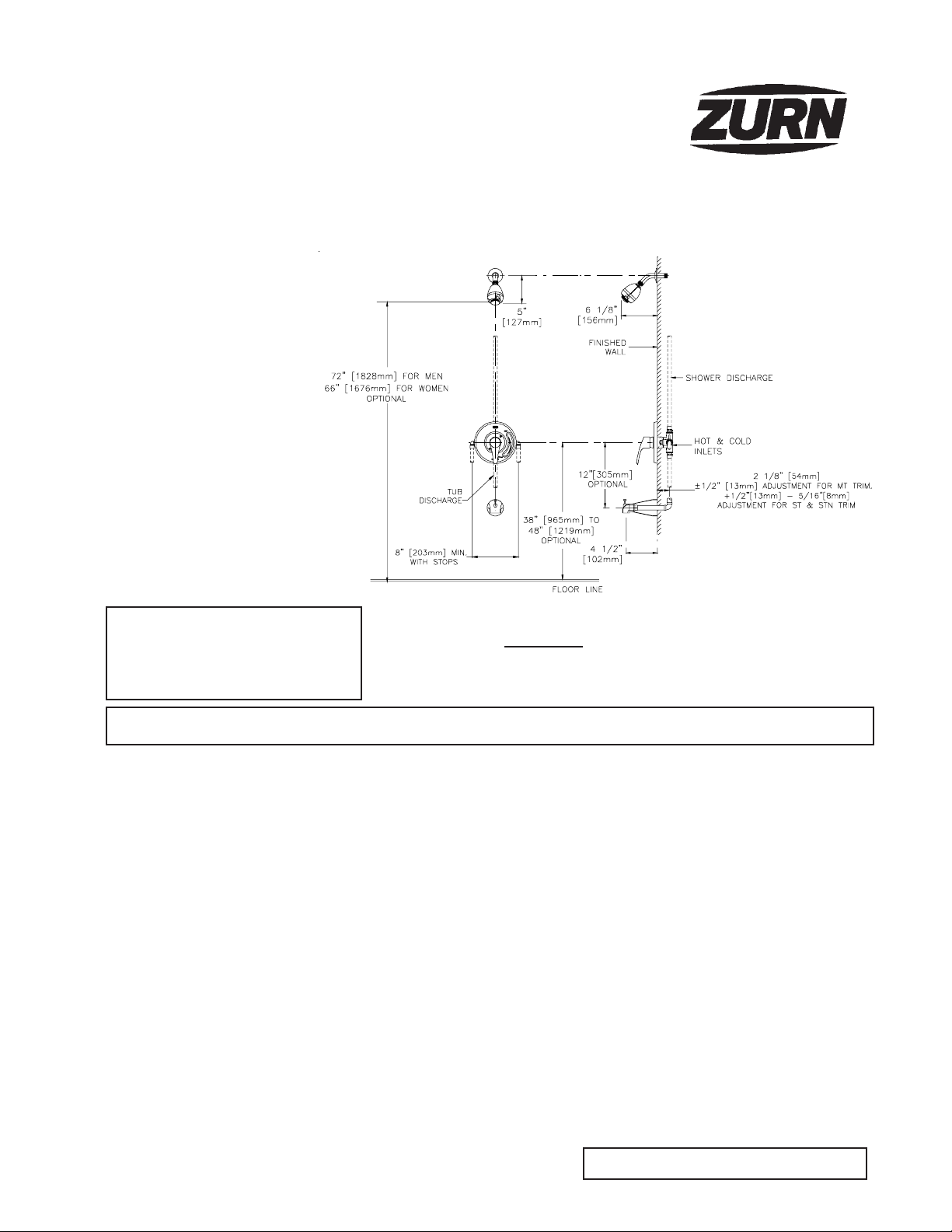

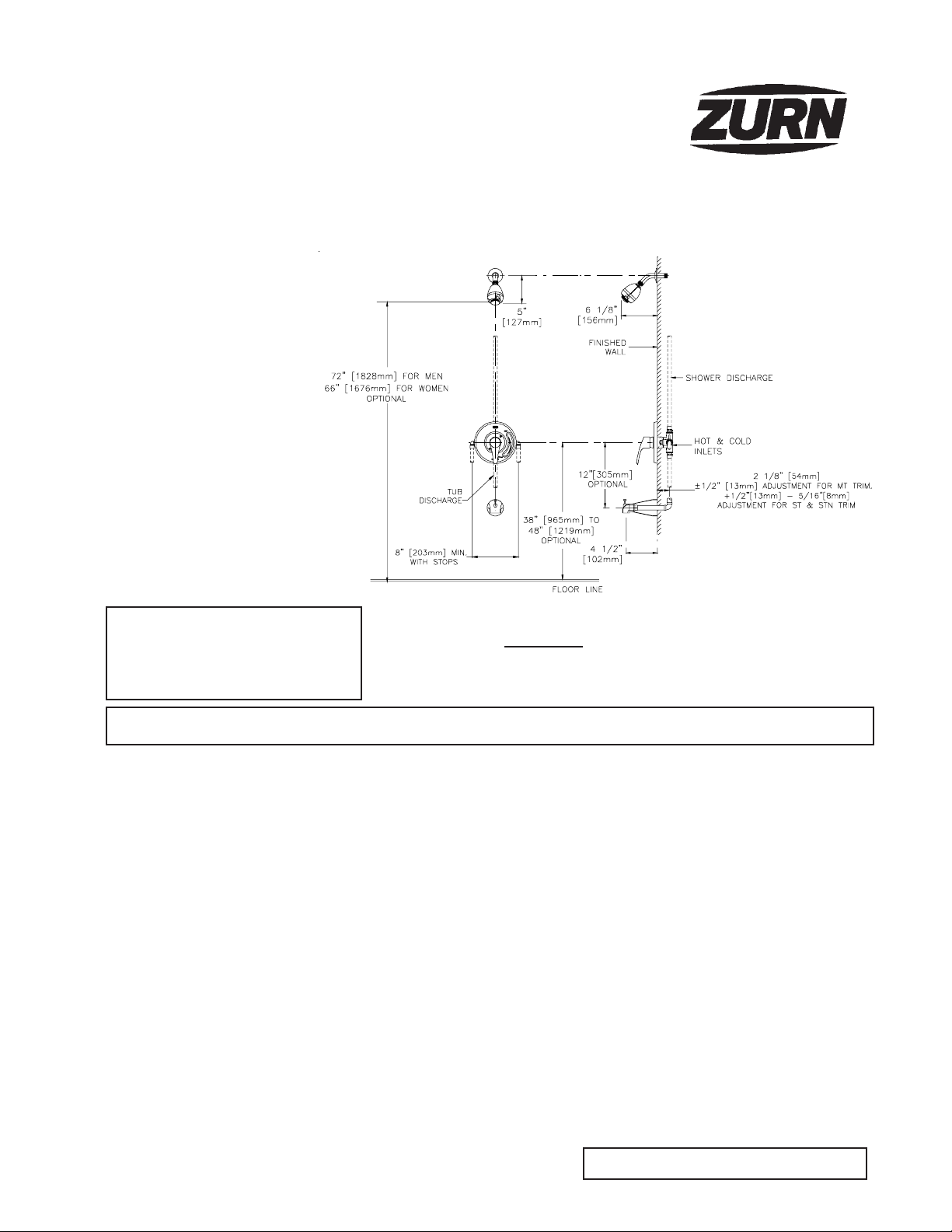

1. Installroughpiping

andvalvebodyas

shown.Do not use

PEX or CPVC CTS piping

from valve to tub spout, as

the reduced ID results in

too much back pressure for

valve to function

properly.When facing

valve,HOT"H" ison

left and COLD "C" is on right.

Tubport“T” should facedown

andshower port “S”should

faceupward. The earson the

valveat the5 o’clock and

11 o’clock positions may

be used to attach the valve to

framingof wallif necessary.

WARNING: Caution should be

taken when heating valve for

sweat connections to avoid dam-

aging internal rubber and plastic

components in valve.

FIGURE 1

®

Form # CF1024 Date: 12/16/11 SHT 1 OF 4

C.N. No. 128417 Rev. G