3D Systems CubePro User manual

Other 3D Systems 3D Printer manuals

3D Systems

3D Systems CUBE User manual

3D Systems

3D Systems FabPro 1000 Manual

3D Systems

3D Systems PROJET 3500 Reference guide

3D Systems

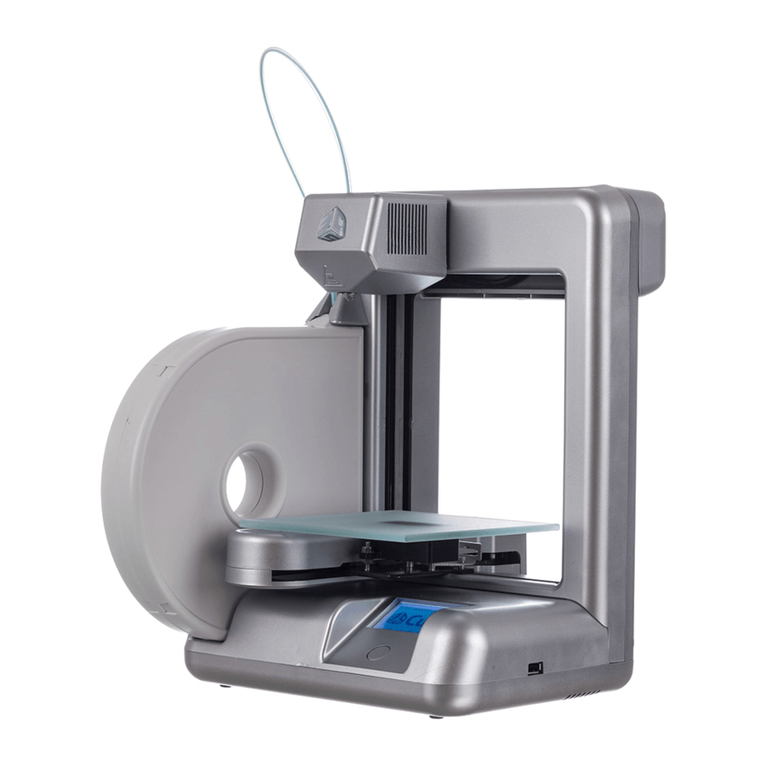

3D Systems CubePro User manual

3D Systems

3D Systems ProX 800 User manual

3D Systems

3D Systems ProX DMP 100 User manual

3D Systems

3D Systems SLA 750 Series User manual

3D Systems

3D Systems ProJet 660Pro User manual

3D Systems

3D Systems Cubify CUBEX Duo User manual

3D Systems

3D Systems ProJet 4500 User manual

3D Systems

3D Systems iPro 8000 SLA Center User manual

3D Systems

3D Systems ProX 950 User manual

3D Systems

3D Systems CUBE User manual

3D Systems

3D Systems ProJet 1200 User manual

3D Systems

3D Systems ProJet MJP 5600 User manual

3D Systems

3D Systems CUBE User manual

3D Systems

3D Systems ZPRINTER 150 User manual

3D Systems

3D Systems Figure 4 Standalone User manual

3D Systems

3D Systems Viper Pro SLA iPro 8000 User manual

3D Systems

3D Systems ProX 500 User manual