2 78-8140-4883-7-A

1.0 Introduction

1.1 The 3M™Fiber Dome Closure FDC 08M can accommodate up to six 0.47” (12 mm) cables when using

the 3M™12 mm External Cable Assembly Module (ECAM) and two 0.79” (20 mm) main cables. The

3M™ Cable Entry Port Kit is designed to accept fiber optic loose tube and central tube cables with external

diameters from 0.16" to 0.47" (4-12 mm) and flat drop (0.18 x 0.32"). It will accommodate cables with

single or dual cable strength members.

The FDC 08M can accommodate both dielectric and armored cables. For armored cables, the grounding

kit must be purchased separately.

Specifications

Closure Tray Capacity: 4

6

3M™Hinged Fiber Optic Splice Tray 2540 for buffer tube cable and ribbon cable OR

3M™Hinged Fiber Optic Splice Tray 2539 for buffer tube cable only

2539 Splice Tray Capacity

2540 Splice Tray Capacity:

12

12

36

Single Fusion Splices

Single Fusion Splices

Mass Fusion Ribbon Splices

Main Cable: 2 0.39” (10 mm) min to 0.79” (20 mm) max diameter

Max Branch Cables: 6 0.16” (4 mm) min to 0.47” (12 mm) max diameter

Ground Lug: 1 1/4 -20 threaded ground stud

Air Valve: 1 5 PSI max (34kPa max) flash

Express Storage: 72” (1.8 m) max of LBT 72F (12 fibers/buffer) / RF 144F

2.0 Kit Contents

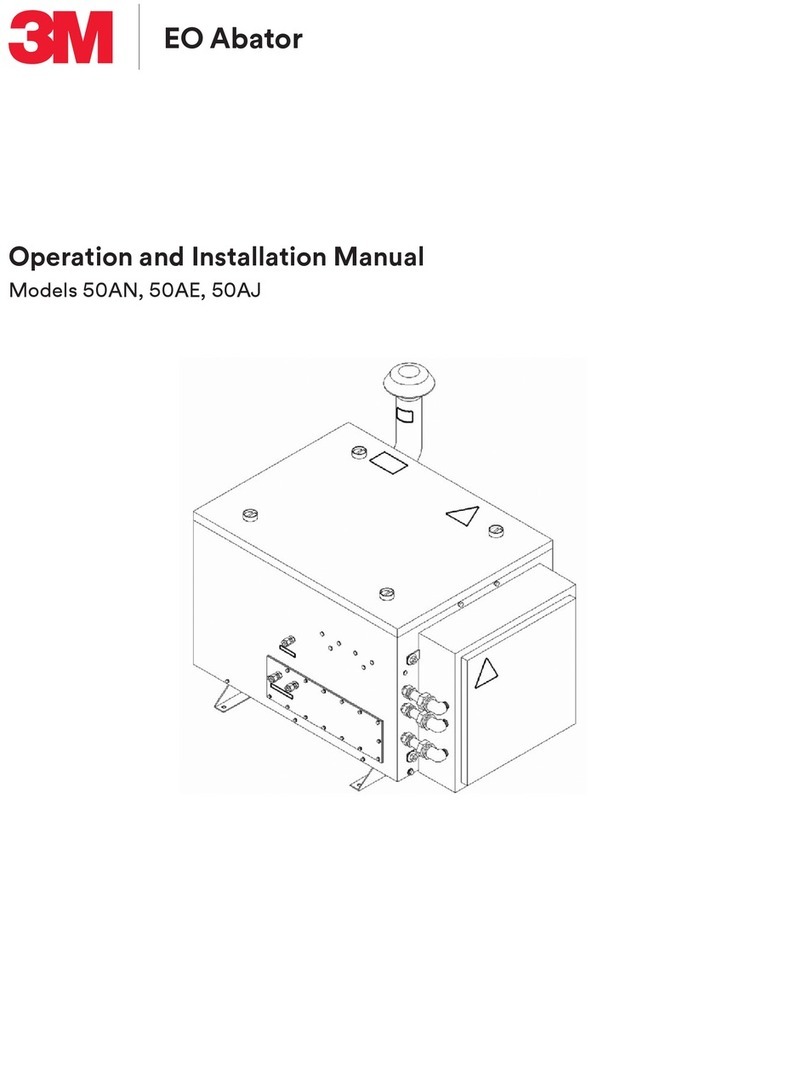

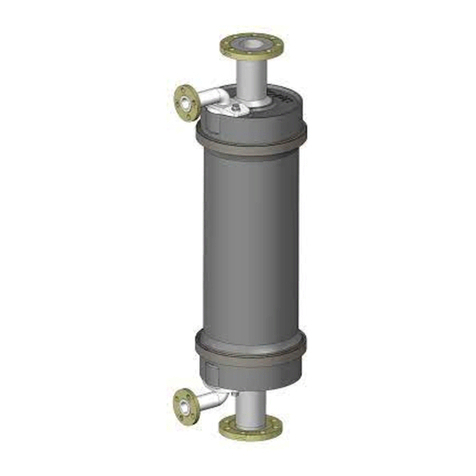

2.1 3M Fiber Dome Closure FDC 08M

B

C

D

E

F I

K

J

A

G

H

A. Dome (size M)

B. Base assembly

C. Storage basket

D. Hinged splice tray bracket for 3M™Fiber Optic Splice Trays 2539 or 2540

E. 3M™Double Cable Entry Port ECAM-20 mm-D

F. 3M™Double Cable Entry Port ECAM-20 mm loose parts

G. Qty (1) 3M™Splice Tray 2540 Assembly

H Qty (1) 3M™ Cable Entry Port ECAM-12 mm Kit

I. 78-8140-3820-0 Instructions for Double Cable Entry Port ECAM-20 mm-D

J 78-8135-6181-4 Instructions for Cable Entry Port ECAM-12 mm

K. Fiber Dome Closure FDC 08M instructions

Visually inspect all components. If any component is missing or appears damaged, do not install.

Call 3M customer service at 1-800-426-8688 for a replacement product.