Tableof Contents

Explanation of Symbols....................................................... 2

Product and package labels andpictograms �������������������������2

Explanation of Symbols: OperatorManual������������������������������3

ContentDisclaimers ........................................................... 3

1.Description .................................................................... 4

2. IntendedUse.................................................................. 5

3.Safety ............................................................................ 6

4. Dangers and FirstAid..................................................... 7

4�1�Dangers���������������������������������������������������������������������������7

4�2� FirstAid����������������������������������������������������������������������������8

5.Warnings ....................................................................... 9

6.Cautions ...................................................................... 10

7.Specifications............................................................... 11

7�1� 3M™Steri‑Vac™ Sterilizer/Aerator GSX Series

StructuralSpecifications������������������������������������������������11

7�2� Sound Power Levels Specifications�������������������������������11

7�3� PowerSpecifications�����������������������������������������������������11

7�4� Air SupplySpecifications �����������������������������������������������12

8. Compliance and ReferenceStandards .......................... 12

8�1� Device SafetyCompliance���������������������������������������������12

8�2� Electromagnetic Compatibility (EMC)Compliance���������12

9. Installation and SetUp.................................................. 13

9�1� Environmental OperatingConditions �����������������������������13

9�2� Room and InstallationRequirements�����������������������������14

9�3� Set up andConnections ������������������������������������������������15

10. Using the TouchScreen.............................................. 18

10�1� MainScreen����������������������������������������������������������������18

10�2�Menu���������������������������������������������������������������������������18

10�3�Reports������������������������������������������������������������������������19

10.3.1. CycleReports......................................................19

10.3.2. Ethylene Oxide UsageReports..............................20

10.3.3. Site SetupReport ................................................21

10.3.4. Printer FormFeed................................................22

10�4� CycleCategories����������������������������������������������������������22

10.4.1. OperatorCycles...................................................22

10.4.2. SupervisorCycles................................................23

10�5� SetupMenu�����������������������������������������������������������������24

10.5.1. SiteSetup...........................................................24

10.5.2. UserSetup..........................................................28

10�6�Status��������������������������������������������������������������������������30

10.6.1.Control................................................................30

10.6.2.Info.....................................................................30

10.6.3.Log.....................................................................30

11. 3M™ CycleProgrammer........................................... 31

11�1� 3M™ Cycle ProgrammerOverview ����������������������������31

11�2�3M™ Cycle Programmer Hardware and

SoftwareRequirements�����������������������������������������������31

11.2.1. HardwareRequirements ......................................31

11.2.2. SoftwareRequirements .......................................32

11�3�Installing the 3M™ CycleProgrammer�����������������������32

11�4�Creating a Cycle in the 3M™ CycleProgrammer�������34

11�5�Defining Set Points for Cycle Stages andParameters �37

11.5.1. PreheatStage .....................................................37

11.5.2. Air RemovalStage...............................................37

11.5.3. Chamber TestStage ............................................37

11.5.4. ConditioningStage ..............................................38

11.5.5. EO InjectionStage...............................................39

11.5.6. EO ExposureStage..............................................40

11.5.7. EO RemovalStage...............................................40

11.5.8. FlushingStage ....................................................41

11.5.9. AerationStage ....................................................42

11.5.10. Save a CustomCycle.........................................42

11.5.11.StandbyStage...................................................43

11.5.12.Estimated Total CycleTime................................43

11�6�Importing Custom Cycles to the 3M™Steri‑Vac™

Sterilizer/Aerator GSXSeries���������������������������������������44

11�7� Running Custom Cycles on the 3M™Steri‑Vac™

Sterilizer/Aerator GSXSeries���������������������������������������47

11�8� Managing Custom Cycles on the 3M™Steri‑Vac™

Sterilizer/Aerator GSXSeries���������������������������������������48

11�9�Replacing Cycles on the 3M™Steri‑Vac™

Sterilizer/Aerator GSX Series With the SameName ����49

11�10�Removing Custom Cycles from the 3M™Steri‑Vac™

Sterilizer/Aerator GSXSeries�������������������������������������50

11�11� CycleReports ������������������������������������������������������������51

11.11.1.Custom Cycle SetPoints....................................51

11.11.2.Export CycleData..............................................52

12. Medical Device Packaging andLoading...................... 53

12�1� Preparing Medical Devices forSterilization �����������������53

12�2� Packaging MedicalDevices�����������������������������������������53

12.2.1. RecommendedPackaging ...................................53

12.2.2. Non‑compatiblePackaging ..................................54

12.2.3. Package MedicalDevices ....................................54

12�3� Loading the 3M™Steri‑Vac™ Sterilizer/Aerator

GSXSeries�������������������������������������������������������������������54

12.3.1. LoadingRecommendations..................................55

12.3.2. Loading Medical Devices andInstruments............55

13. OperatingInstructions ................................................ 56

13�1� Starting aCycle �����������������������������������������������������������56

13�2� Display ScreenIndications ������������������������������������������65

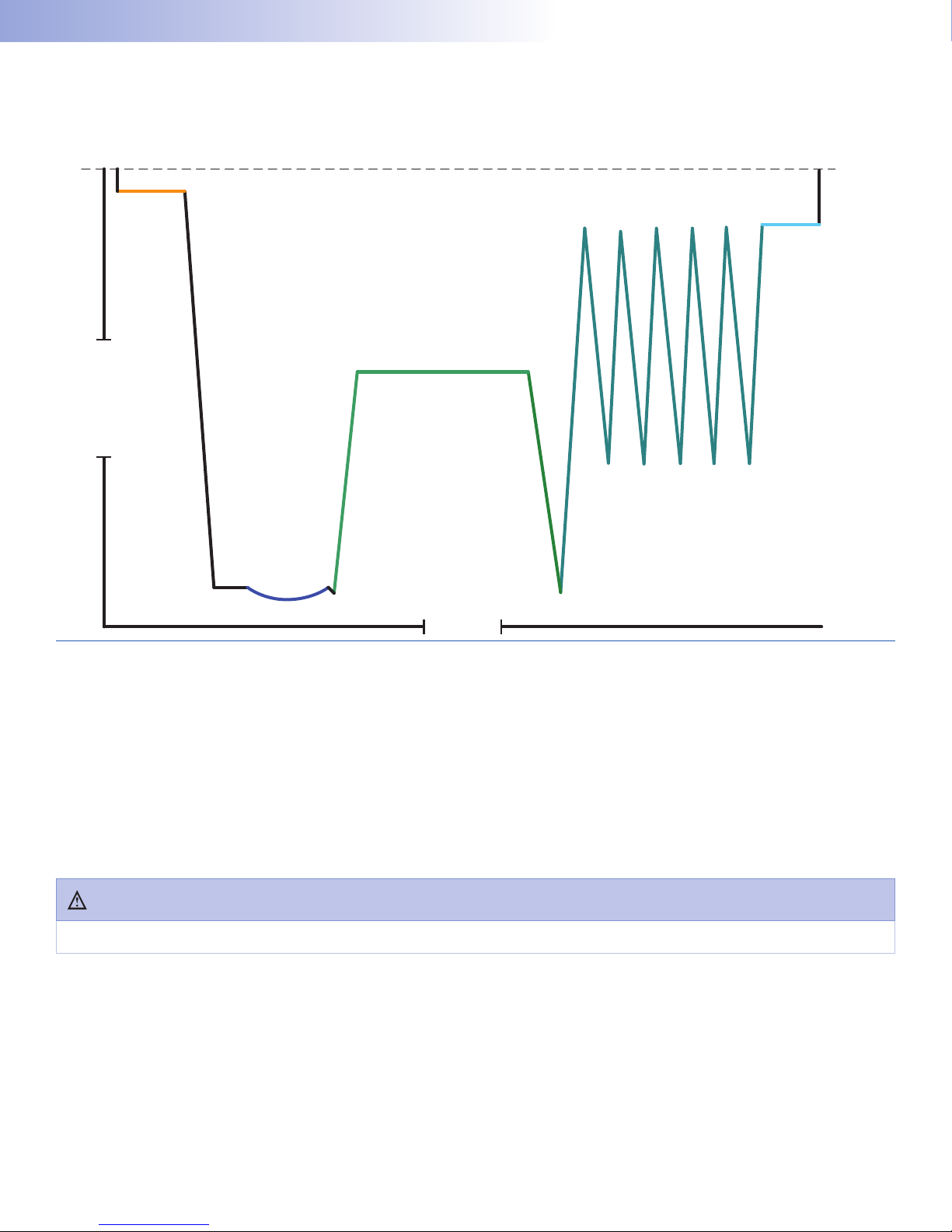

13�3� Overview of GSX Series Ethylene Oxide

(EO)SterilizationCycle�������������������������������������������������66

13.3.1. Cycle Stages andDescriptions.............................66

13.3.2. CycleReports......................................................67

13�4�Cartridge Dispose Cycle for 3M™Steri‑Gas™

EOGasCartridges �������������������������������������������������������70

13�5�EthernetConnection����������������������������������������������������70

13.5.1.NetworkConnections ..........................................70

13.5.2.IPAddresses.......................................................70

13.5.3.SoftwareSecurity ................................................71

13.5.4.SoftwareUpdates................................................71

13.5.5.FirmwareUpdates ...............................................71

13�6�Distilled WaterReservoir ���������������������������������������������72

13�7�PrinterOverview����������������������������������������������������������72

13�8�Unloading the 3M™Steri‑Vac™ Sterilizer/Aerator

GSXSeries�������������������������������������������������������������������72

13.8.1. Unloading the 3M™Steri‑Vac™ Sterilizer/Aerator

GSX Series – CycleComplete ..............................73

13�9� Accessing the Chamber – Aeration NotComplete�������74

13�10� Empty 3M™Steri‑Gas™ Ethylene Oxide

(EO)GasCartridges ���������������������������������������������������75

13�11� Aeration of a Biological Indicator Process

ChallengeDevice (BIPCD)�����������������������������������������75

13�12�Sterilization CycleCancellations��������������������������������75

13.12.1. Manual CycleCancellation.................................75

13.12.2. Automatic CycleCancellation.............................75

13�13�PowerOutages����������������������������������������������������������75

14. Process Monitoring and LoadRelease ........................ 76

14�1�Physical Parameters andRequirements����������������������76

14�2� Biological Indicators and Process ChallengeDevices��78

15. RoutineMaintenance ................................................. 79

15�1� DailyCleaning �������������������������������������������������������������79

15�2� Air Supply LineFilters��������������������������������������������������79

15�3� PreventativeMaintenance�������������������������������������������80

16. Cautions, Error Messages, andTroubleshooting.......... 81

16�1� CautionMessages�������������������������������������������������������81

16�2� ErrorMessages �����������������������������������������������������������82

16�3� Error Levels and CorrectiveActions�����������������������������83

17. Repair andReplacement............................................ 85

18. PreventativeMaintenance .......................................... 85

19. Ordering Accessories andSupplies............................. 86

20. 3M™ Cycle Programmer Support

and SoftwareUpdates................................................ 87

ContactInformation��������������������������������������������������������������87

U�S� OrderingInformation�����������������������������������������������������87

Orders for Supplies (e�g� 3M™Steri‑Gas™ EO Gas

Cartridges, 3M™ Attest™ Biological Indicators, 3M™

PrinterPaper)*����������������������������������������������������������������������87