3M Adflo Maintenance manual

Other 3M Safety Equipment manuals

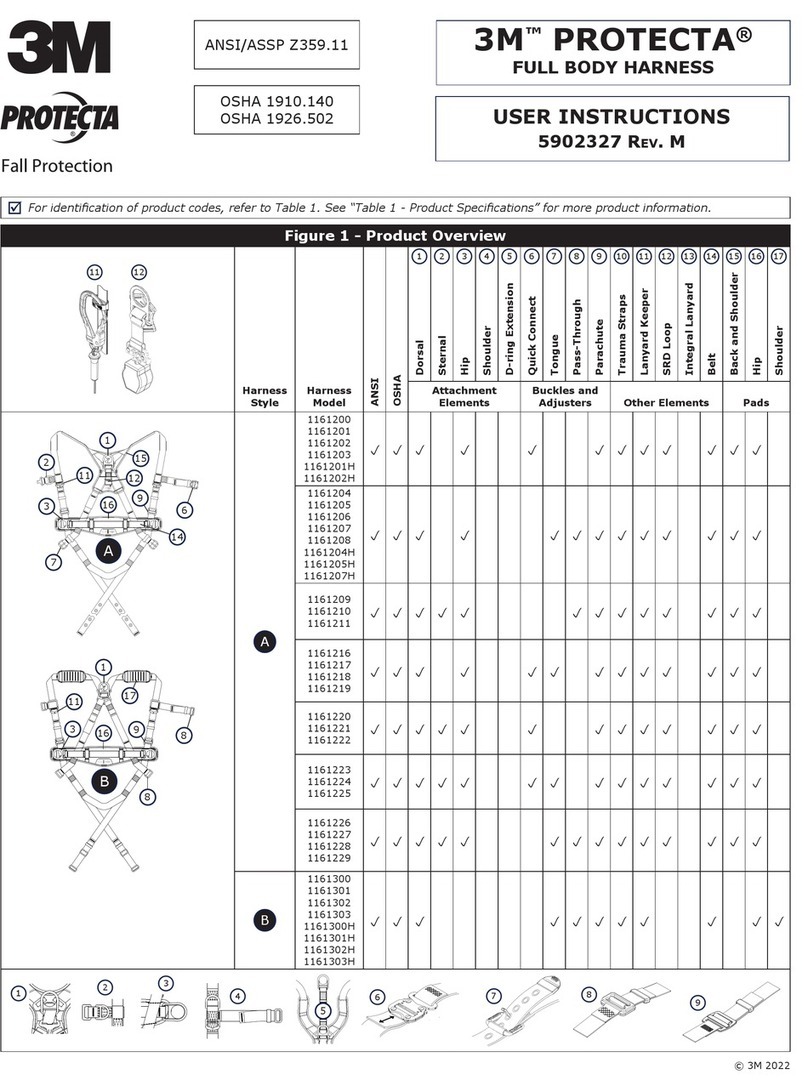

3M

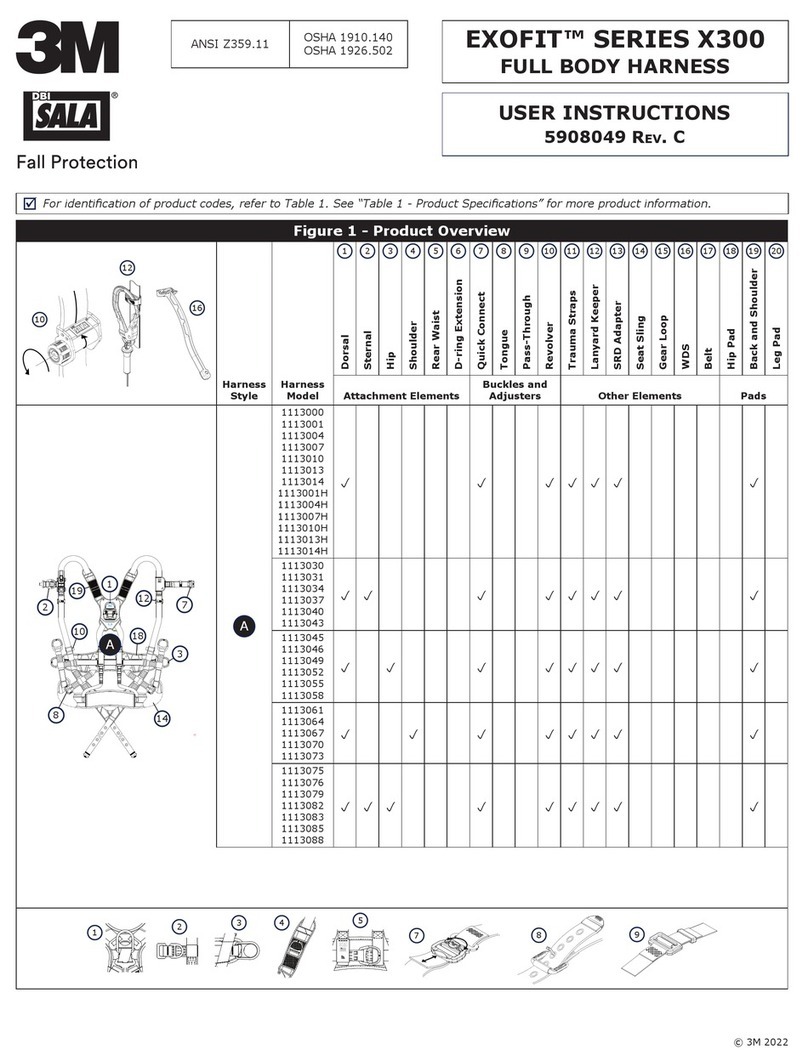

3M 1113000 User manual

3M

3M 306S1043 User manual

3M

3M DBI SALA 2104700 Operator's manual

3M

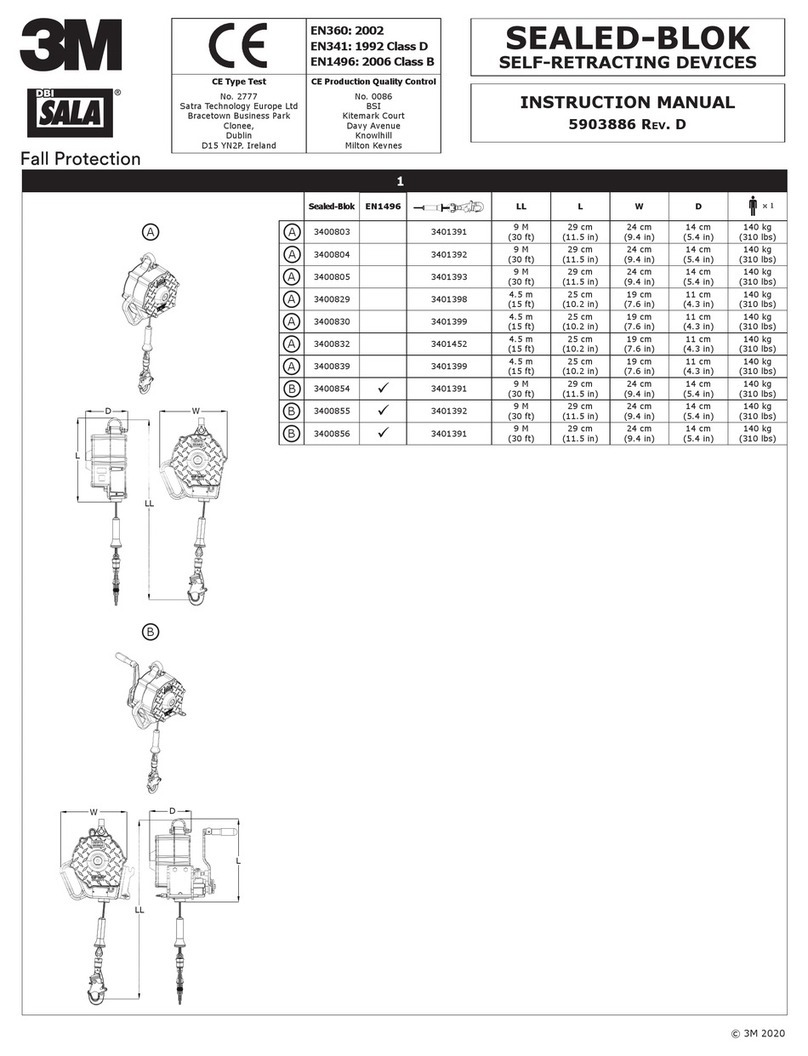

3M DBI SALA Sealed-Blok 3400803 User manual

3M

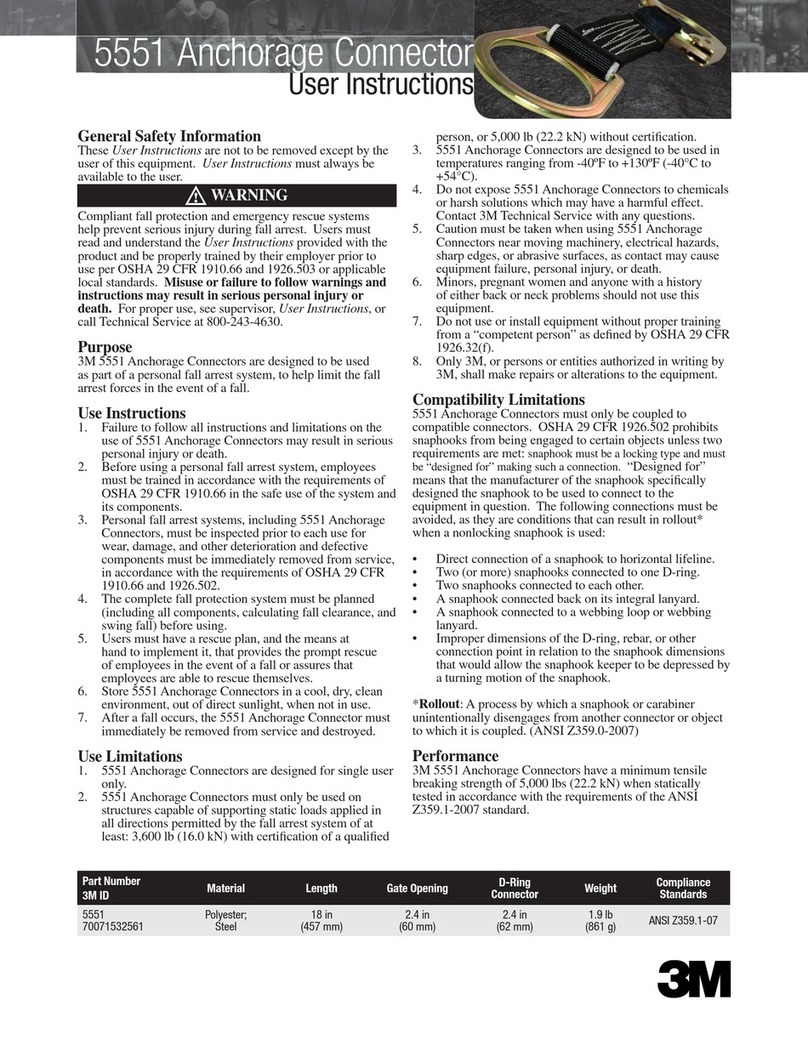

3M 5551 User manual

3M

3M JUPITER Installation instructions

3M

3M Mesh Face 5B User manual

3M

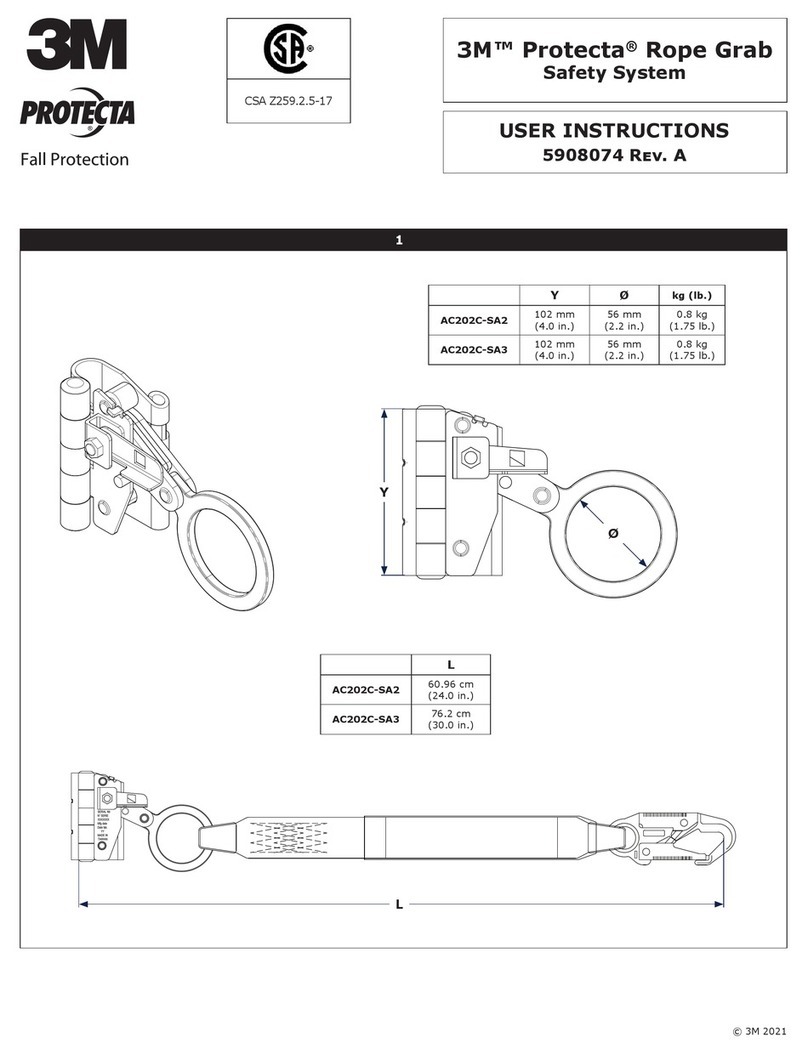

3M Protecta AC202C-SA2 User manual

3M

3M Peltor Optime H510A User manual

3M

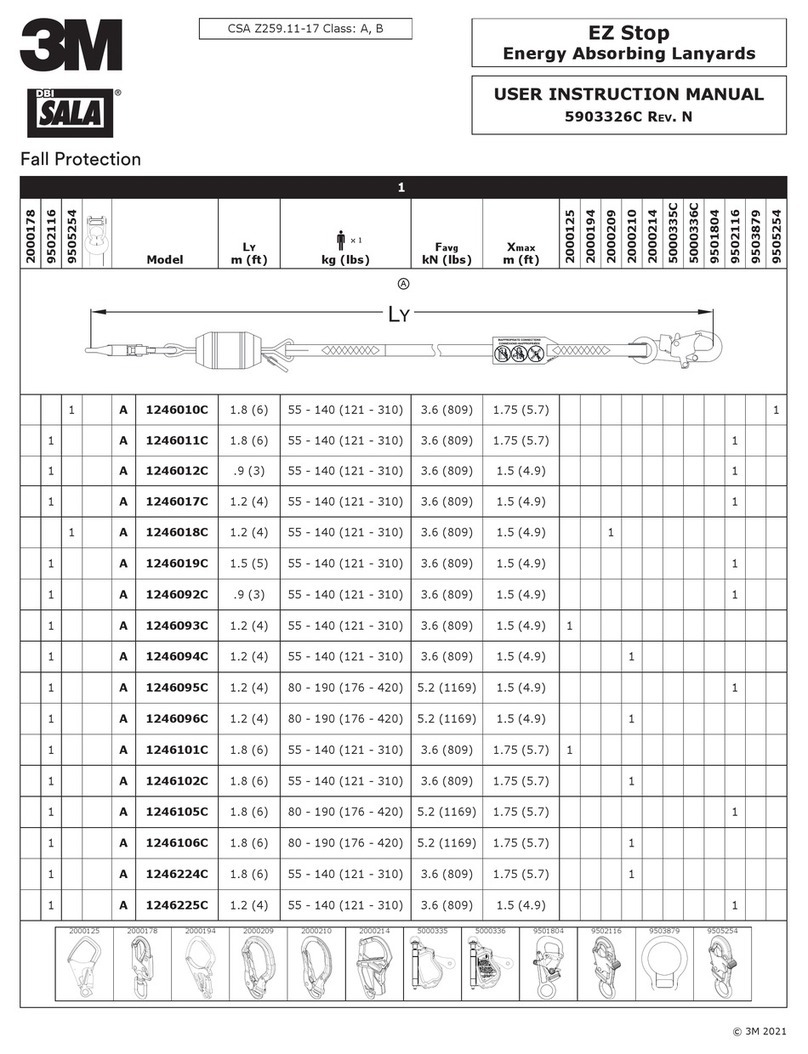

3M DBI SALA 1246010C Operator's manual

3M

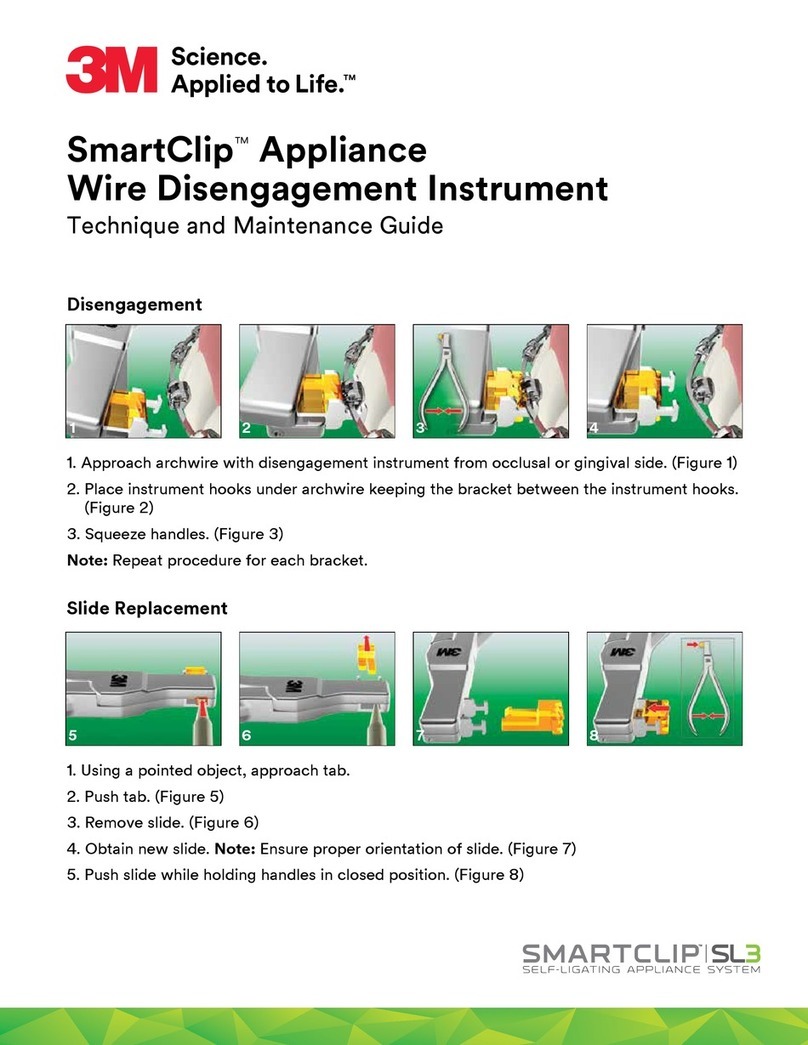

3M SmartClip SL3 Operating manual

3M

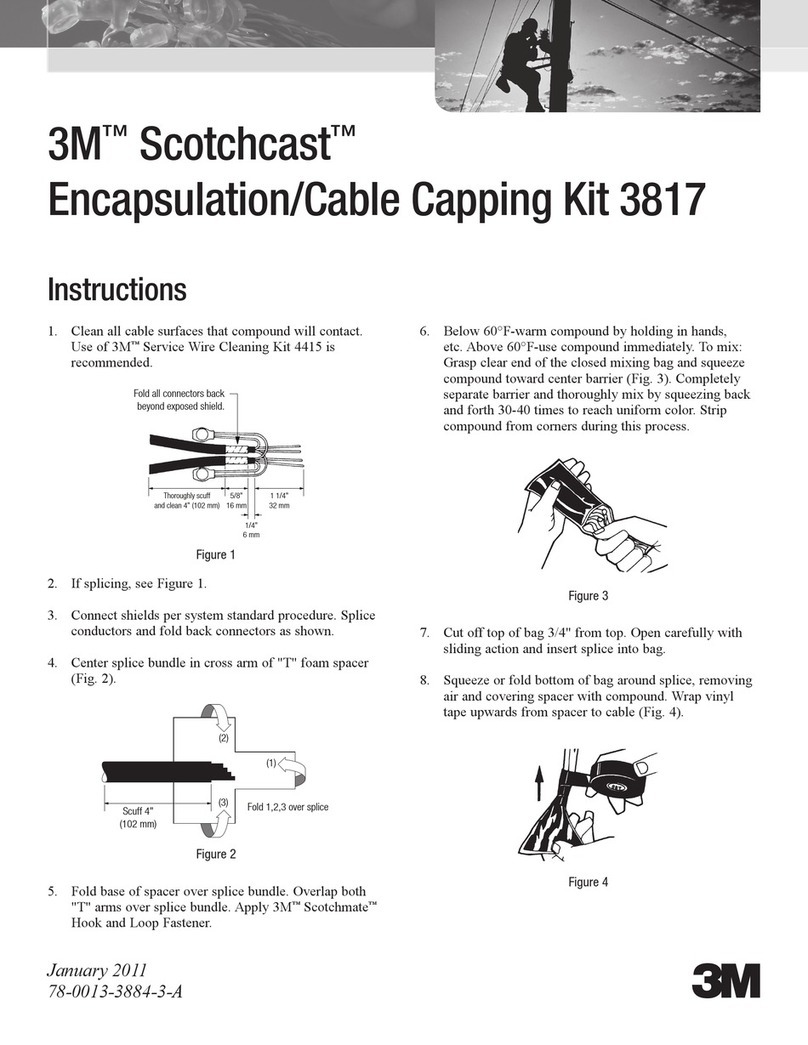

3M Scotchcast 3817 User manual

3M

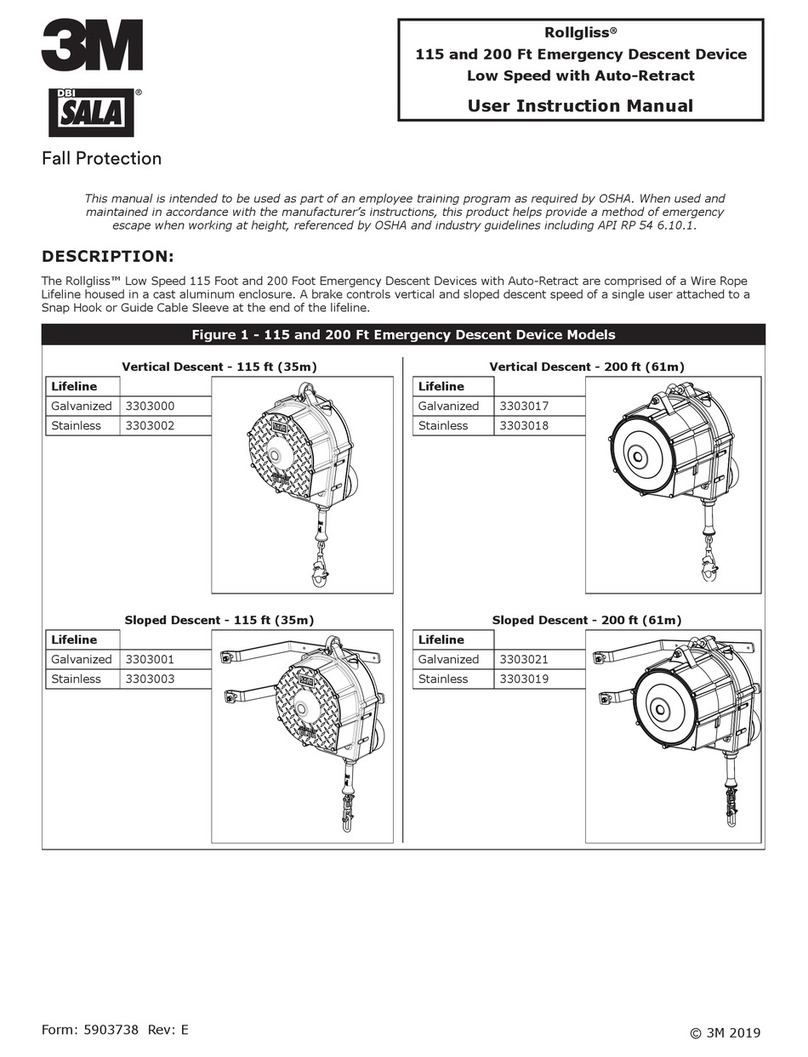

3M DBI SALA Rollgliss 115 Ft Operator's manual

3M

3M ULTRA-LOK Series User manual

3M

3M Peltor TEP-300 User manual

3M

3M PROTECTA COBRA AC202/01 Operator's manual

3M

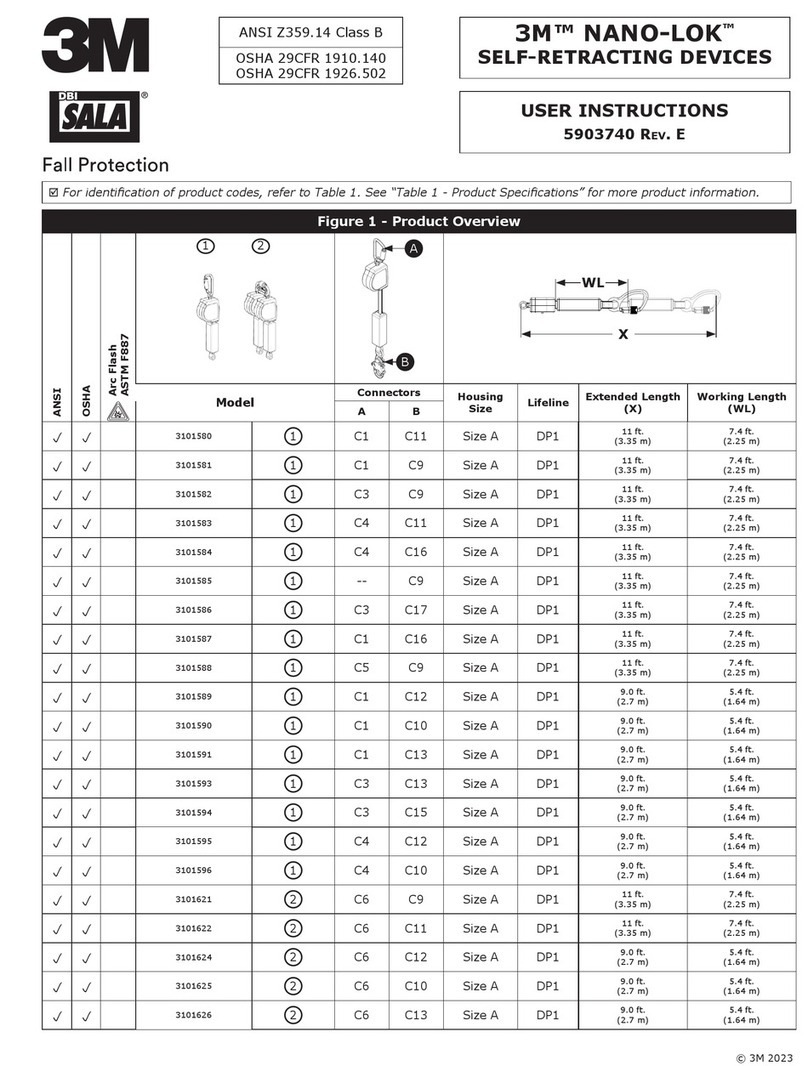

3M DBI SALA NANO-LOK 3101580 User manual

3M

3M PROTECTA AF725 Operator's manual

3M

3M PROTECTA 2 VIPER AC405 User manual

3M

3M SCOTT AIR-PAK X3 PRO Installation and operation manual

Popular Safety Equipment manuals by other brands

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual