MEDIUM VOLTAGE PRODUCTS 55

—

2. Introduction and safe pratices

2.1. Introduction

The purpose of this manual is to provide

instructions for unpacking, storage, installation,

operation, and maintenance for VM1/A/P vacuum

circuit breaker. This manual should be carefully

read and used as a guide during installation, initial

operation, and maintenance.

The specific rating of each model circuit breaker

are listed on the individual nameplate. The VM1/

A/P circuit breaker are protective device. As such,

they are maximum rated device.

In no event should they be applied outside of their

nameplate ratings.

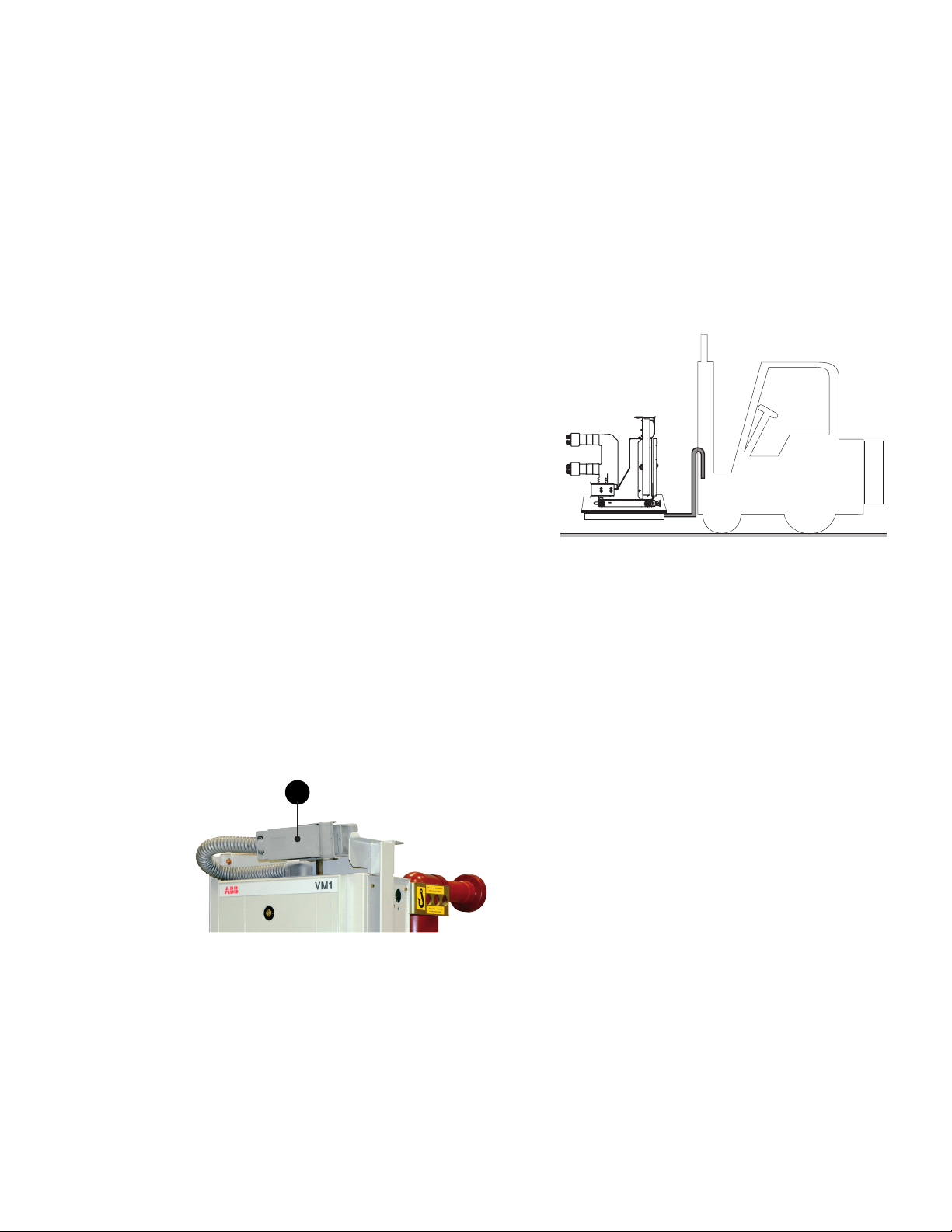

The VM1/A/P type vacuum circuit breakers are

switchgear.

In respect of the technical characteristics, VM1/

A/P circuit breakers are suitable for operation of

electric circuits under normal and fault service

conditions.

The vacuum circuit breakers have particular

advantages when used in systems with a high

frequency of operations and/or which lead to a

type vacuum circuit breakers stand out for their

particularly high operating reliability, extremely

long useful life expectancy and for being

The VM1/A/P type vacuum circuit breakers are

available in the withdrawable version. The basic

structure is shown in the “Technical data” section.

2.2. Safe practices

VM1/A/P circuit breakers are equipped with high

energy / high speed mechanisms. The design

includes several interlocks and safety features

which help ensure safe and proper operating

sequences. To ensure safety of personnel

associated with installation, operation, and

maintenance of these circuit breakers, the following

recommendations must be followed:

Only qualified persons, as defined in the National

Electric Safety Code, who are familiar with the

installation and maintenance of medium voltage

circuits and equipment should be permitted to work

on these circuit breakers

Read these instructions carefully before attempting

any installation, operation, or maintenance of these

power circuit breakers.

Do not work on an energized circuit breaker.

Do not work on a circuit breaker unless all

components are disconnected by means of a

visible break and securely grounded.

Do not work on a circuit breaker with power

supplied to the secondary control circuit.

Do not defeat safety interlocks. This may result in

bodily injury, death and/or equipment damage.

Do not work on a closed circuit breaker.

Do not work on a circuit breaker with charged

energy capacitors.

Do not use a circuit breaker by itself as the sole

means of isolating a high voltage circuit.

Do not leave a circuit breaker in an intermediate

position in a cell. Always place the circuit breaker

in the disconnect, test or connect position.

WARNING

The circuit breakers described in this book

are designed and tested to operate within

their nameplate rating. Operation outside

of these ratings may cause equipment to

fail, resulting in property damage, bodily

injury and/or death.

All safety codes, safety standards and/or

regulations as they may be applied to this

type of equipment must be adhered to

strictly.

NOTE

Failure to observe the requirements of

osha standard 1910.269 Can cause death

or severe burns and disfigurement. That

standard specifically prohibits the

wearing of polyester, acetate, nylon, or

rayon clothing by employees working with

exposure to electric arcs or flames.