6

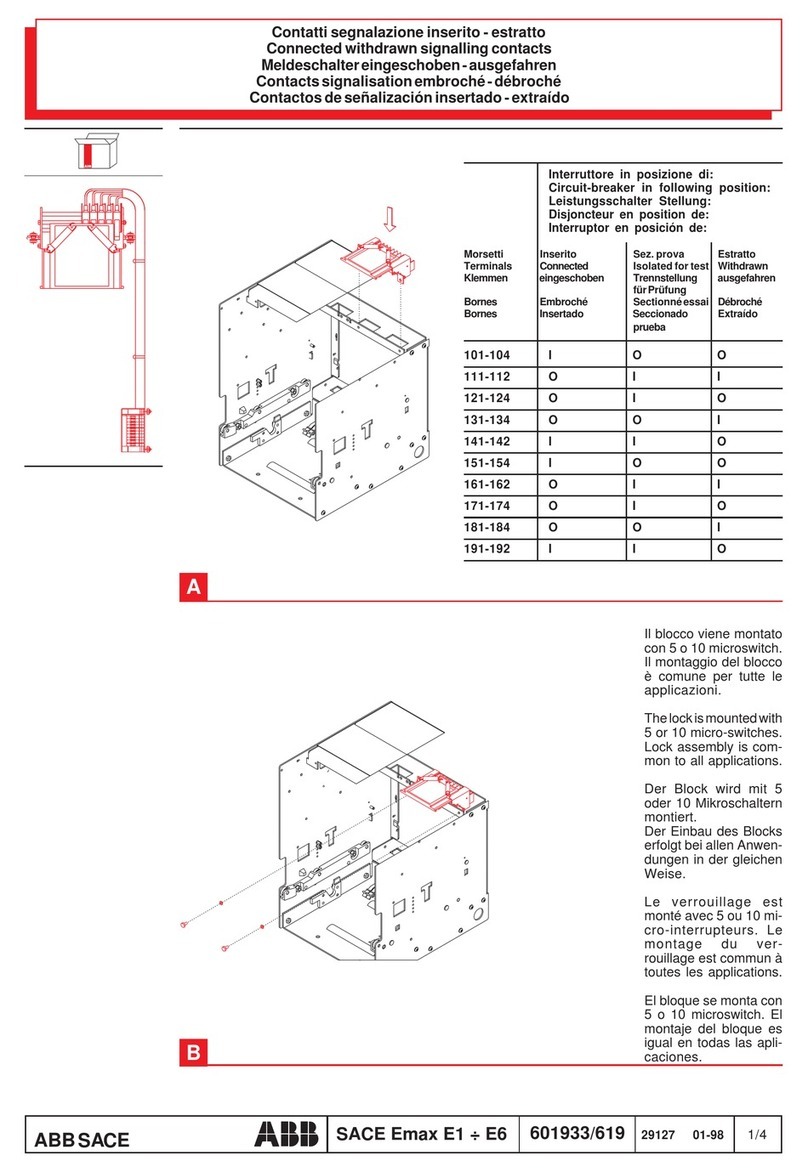

A

B

3

4

2

1

5

3. Reveiving, handling, and storage

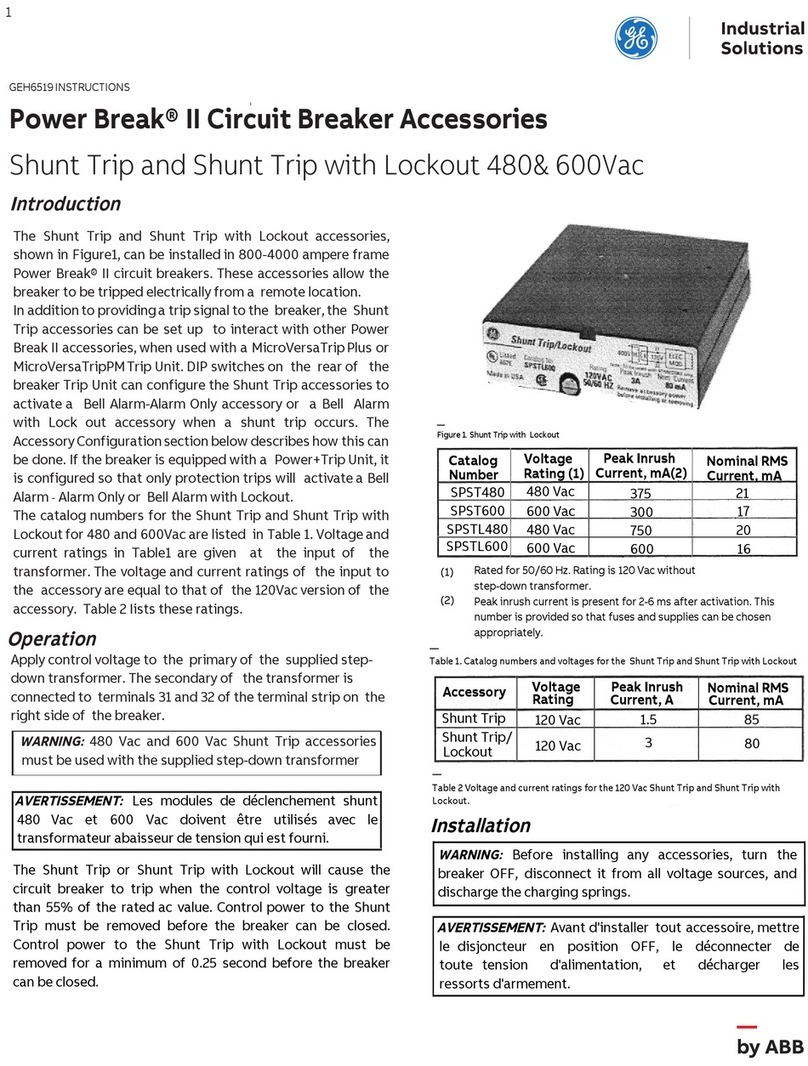

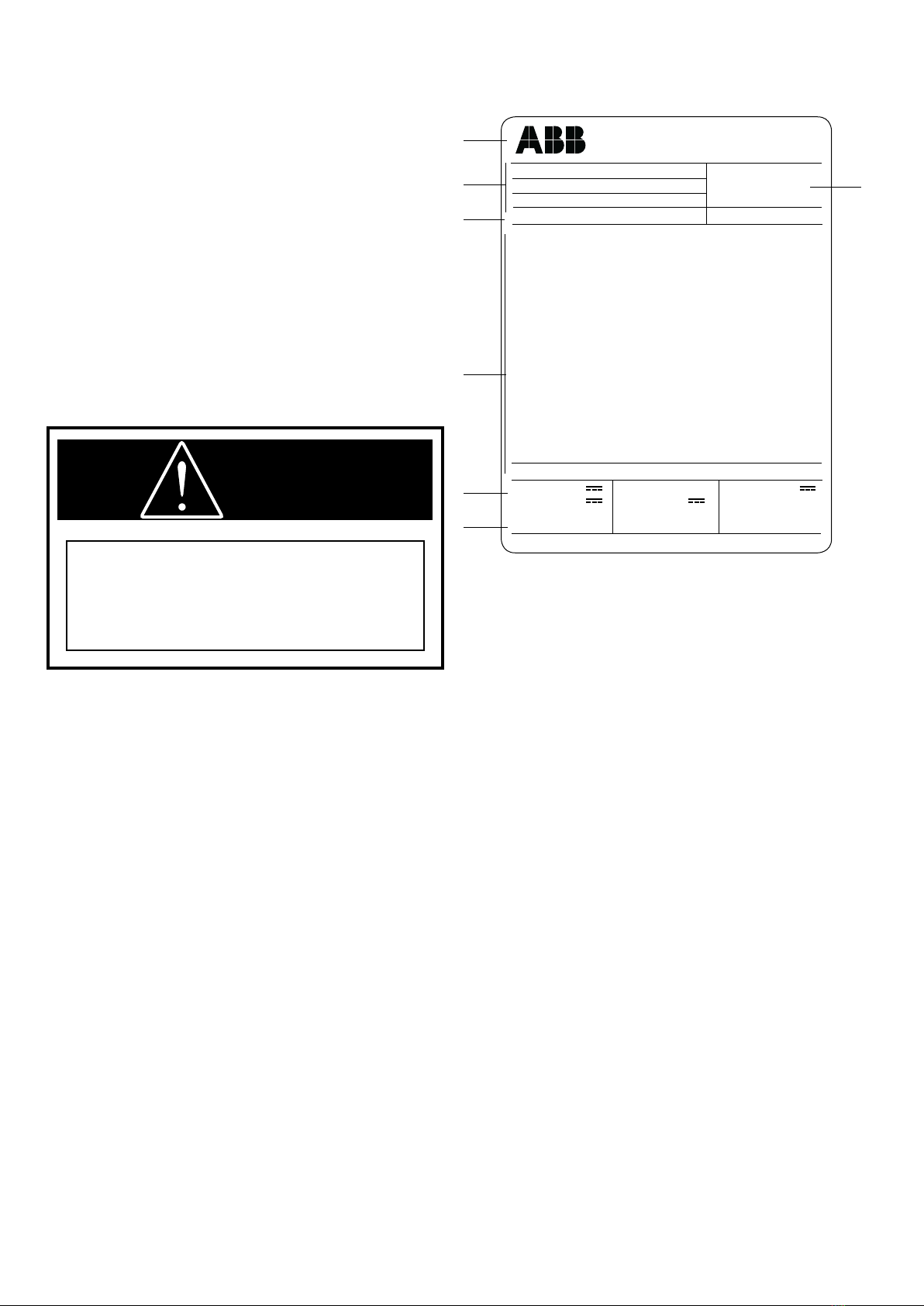

Fig. 1

Caption

A Circuit-breaker rating plate.

B Operating mechanism rating plate.

1 Type of apparatus.

2 Symbols of compliance with Standards.

3 Serial number.

4 Circuit-breaker characteristics.

5 Characteristics of the operating mechanism auxiliaries.

Vmax/W and Vmax circuit-breakers are subject to complete

factory production tests and inspection prior to packaging

and shipment. The shipping package is designed to provide

reasonable protection during shipment and to provide

convenient handling. Accessories such as opening handles

and racking handles are shipped separately from the circuit-

breaker.

The circuit-breaker is shipped in special packing, in the open

position.

Each piece of apparatus is protected by a plastic cover

to prevent any infiltration of water during the loading and

unloading stages and to keep the dust off during storage.

3.1. Receiving

Immediately upon receipt of the circuit-breaker(s), examine

the carton(s) to determine if any damage or loss was

sustained during transit. If damage or indication of rough

handling is evident, file a damage claim at once with the

carrier and promptly notify the nearest district office. ABB

is not responsible for damage to goods which occur after

delivery. However, ABB will lend assistance if notified of

claims. Use care in unpacking the circuit-breaker to avoid

damaging any circuit-breaker parts.

Unpack circuit-breakers as soon as possible after receipt.

If unpacking is delayed, difficulty may be experienced in

making a claim for damages not evident upon receipt.

Check the contents of each carton against the packing list

before discarding any packing material. If any discrepancy

is discovered, promptly notify the nearest district office.

Information specifying the purchase order number, carton

number, and part numbers of damaged or missing parts

should accompany the claim.

On receipt, check the state of the apparatus, integrity of the

packing and correspondence with the nameplate data (see

fig. 1) with what is specified in the order confirmation and in

the accompanying shipping notes.

Also make sure that all the materials described in the shipping

notes are included in the supply.

Should any damage or irregularity be noted in the supply

on unpacking, notify ABB (directly or through the agent or

supplier) as soon as possible and in any case within five days

of receipt.

The apparatus is only supplied with the accessories specified

at the time of ordering and validated in the order confirmation

sent by ABB.

The accompanying documents inserted in the shipping

packing are:

– instruction manual (this document)

– test certification

– identification label

– copy of the shipping documents

– electric wiring diagram.

Other documents which are sent prior to shipment of the

apparatus are:

– order confirmation

– original shipping advice notes

– any drawings or documents referring to special

configurations/conditions.

BEFORE CARRYING OUT ANY OPERATION,

ALWAYS MAKE SURE THAT THE SPRINGS

ARE DISCHARGED AND THAT THE

APPARATUS IS IN THE OPEN POSITION.

CAUTION

CIRCUIT-BREAKER ANSI C37.04

Vmax/W 15.12.31

SN 1VC1 BA 000000XX PR. YEAR 2010

M MASS 84 kg

Ur VOLTAGE 15 kV

Up LIGHTNING IMPULSE WITHSTAND VOLTAGE 95 kV

fr FREQUENCY 60 Hz

Ir NORMAL CURRENT 1200 A

Ik SHORT TIME WITHSTAND CURRENT 31.5 kA

tk DURATION OF SHORT CIRCUIT 2 s

Ise SHORT CIRCUIT BREAKING CURRENT 31.5 kA

MAKING CAPACITY (PEAK VALUE) 82 kA

AT THE VOLTAGE OF 15 kV

D.C. COMPONENT < = 44 %

RATED CLOSING TIME 45 ... 80 ms

RATED INTERRUPTING TIME < = 50 ms

OPERATING SEQUENCE O-0,3S-CO-3MI N-CO

INSTRUCTION MANUAL 1VCD600929

E. lECTRICAL DIAGRAM 1VCD400054 (E1010) \~ I

FIG.01 FIG.02 FIG.07 FIG.OS FIG.33 ~ ~\,

llllllllIIlllllllIlllllllIllllllllllllllllllIlIlllllllIlllllllIllllllllll

EL1 OPERATING MECHANISM

-MC 125 V -MS 125 V

-M01 125 V -RL2 125 V

Made by ABB, Italy