DISPATCH AND STORAGE 9

1.1 Condition on delivery

The panels have been routine tested to IEC 62271-200

| GB 3906.

•In normal cases, the gas compartments have

been filled with insulating gas to the rated filling

pressure. When airfreighted, however, the panels

are delivered with reduced pressure.

•If airfreight with PrimeGear ZX0 panels is needed,

please contact ABB for further guidance.

•The individual parts of the busbars, the installation

material and accessories and the documentation

are packaged separately from the panels.

When the busbars are removed from the

packaging, do not lay them on their

silicone surfaces. As the copper is very

heavy, the silicone can be damaged even

if the components are incorrectly stored

for a short period only. Always use the

spacers supplied for storage.

1.2 Delivery

Check the consignment for completeness and

freedom from damage. Document any transport

damage found on the waybill and inform us of it

immediately. Take photographs of the damage.

1.3 Packaging

The panels have been prepared for transport by

the agreed method and for the desired duration

of any interim storage required. Details of the

length of preservation and the storage location

(indoors or outdoors) can be found in the order

documents. If the panels are packaged, they are

mounted on a pallet and secured to prevent them

from slipping.

The possible packaging methods are as follows:

•No packaging.

•Packaged in plastic sheeting.

•Packaged in plastic sheeting and surrounded by

protective cardboard.

•Heat sealed in plastic sheeting with drying

agent enclosed.

•Packaged in aluminum foil in transport crate

with drying agent enclosed.

1.4 Handling

The transport units are the panels.

Always handle the panels in the upright

position.

Take account of the weight of the transport

units when selecting the handling

equipment.

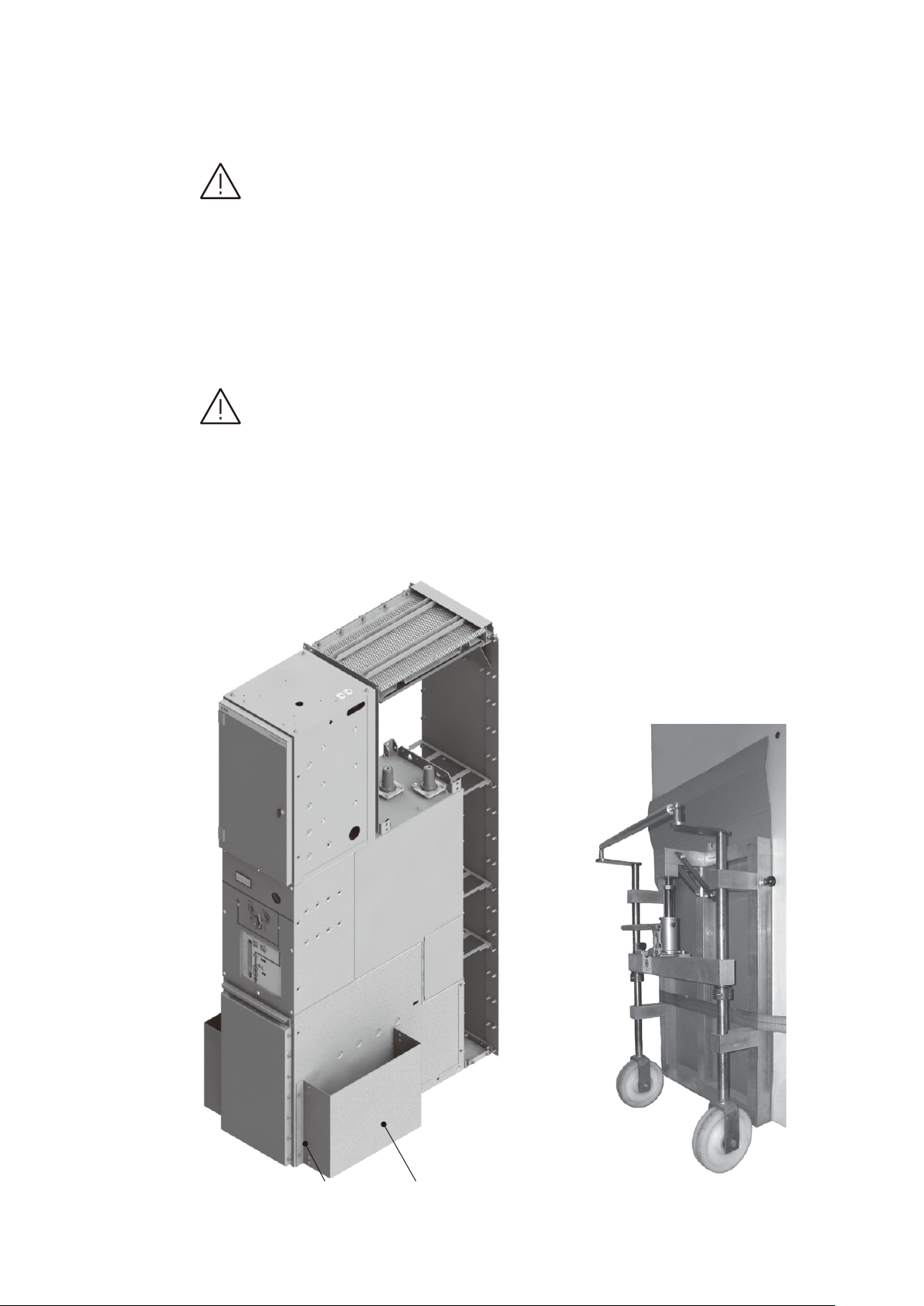

Due to the high centre of gravity of the

panels, there is a risk that the transport

units may tip over! Take all precautions to

protect personnel and the materials

transported. When using hydraulic lift

trolleys to transport panels of 450 mm

width or during positioning of the panels

on the foundation rails, there is a high risk

of them tipping. Therefore always fit lateral

support plates as shown in Fig. 1.4.3.1 to

prevent them from doing so.

Only ever handle the panels by

•forklift truck.

•trolley jack.

•crane, or.

•hydraulic lift trolley (Support plates required for

panels of 450 mm width!).

1.4.1 Handling by forklift truck or trolley jack

The panels must each be mounted on a

pallet and secured with straps. The pallet

must rest fully on the forks of the truck

or jack. The high centre of gravity means

there is a high risk of tipping. Avoid jerky

motions.

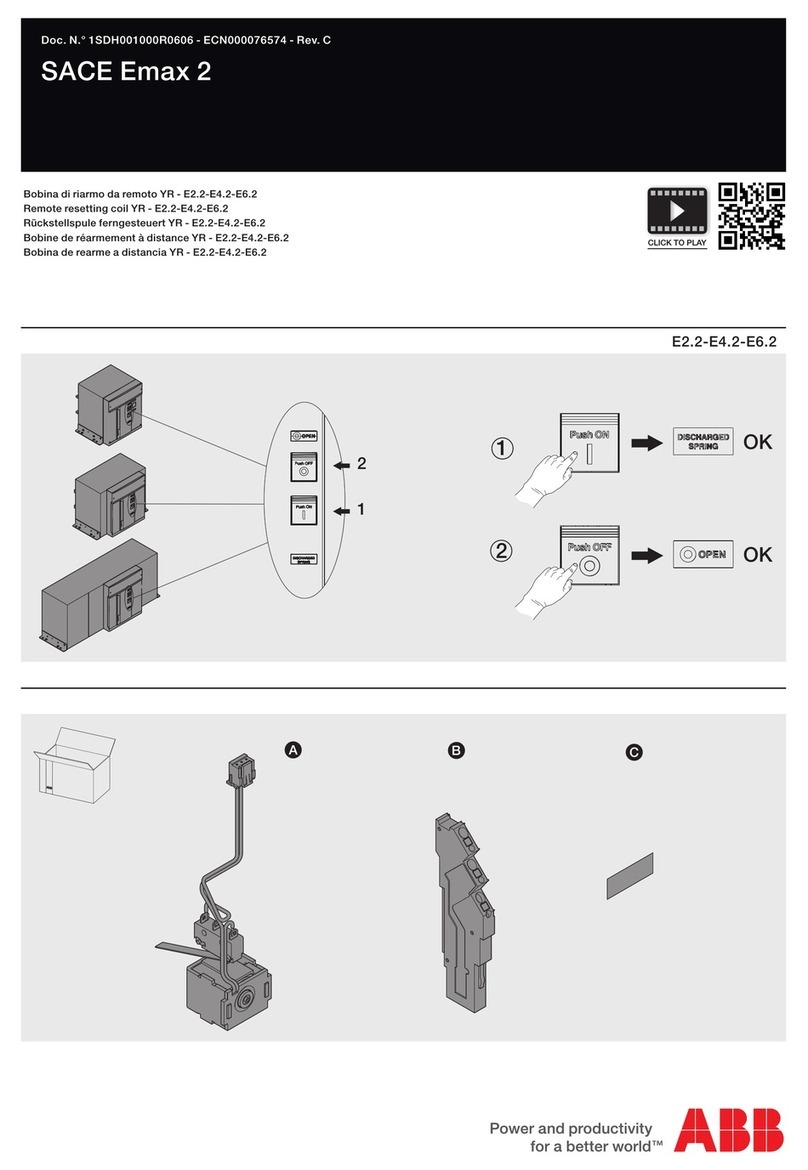

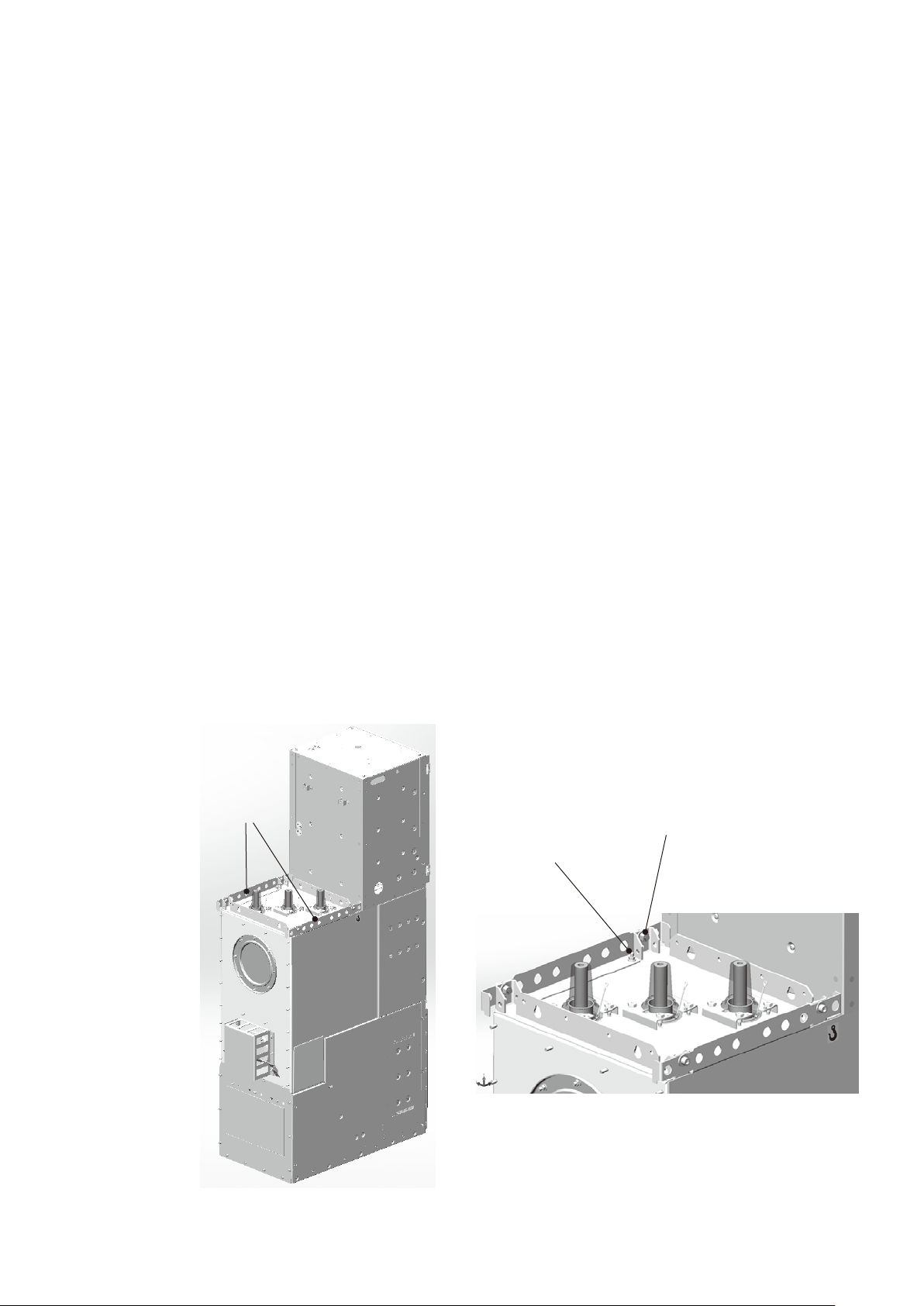

1.4.2 Handling by crane

•As shown in Fig.1.4.2.1, fasten one lifting

bracket each to the left and right of the roof

section and U shape parts of the panel module,

using two M12 X 30 cheese-headscrews with

dished washers & nuts and three M8 dished

washer & nuts in each case.

•Attach suspension ropes of a sufficient load

bearing capacity (see section 11, Technical data,

for the panel weights) and sufficient length to

the lifting brackets using shackles thread the

suspension ropes through the cutouts in the

rope guides. The ABB scope of supply does not

include suspension ropes and shackles.

Lifting brackets

M8 dished washers & Nuts

M12x30 cheese-head screw

with dished washers & nut

—

Fig. 1.4.2.1: Preparing a

panel for handling by

crane

—

Fig. 1.4.2.1