Page 3 Infinity S_Dual V_old_QSG Version 4.0

© 2021 ABB. All rights reserved.

Déclarations de sécurité

Precautions

• Installer, mettre en service et utiliser l'équipement uniquement par du personnel professionnel, compétent et qualifié

possédant les connaissances et l'expérience pratique nécessaires en matière d'équipement électrique et qui comprennent

les dangers qui peuvent survenir lors de l'utilisation de ce type de Équipement.

• Débranchez les piles des sorties et/ou suivez les procédures de sécurité tout en travaillant sur l'équipement. Les batteries

peuvent être connectées parallèlement à la sortie des redresseurs. Éteindre les redresseurs n'enlèva pas forcément

l'alimentation du bus.

• Ne débranchez pas les raccords de liaison permanents à moins que toutes les entrées d'alimentation ne soient

déconnectées.

• Vérifiez que l'équipement est correctement mis à la terre avant de brancher l'appareil. Des courants de fuite élevés peuvent

être possibles.

• Exercez des soins et respectez tous les avertissements et pratiques de sécurité lors de l'entretien de cet équipement.

L'énergie et les tensions dangereuses sont présentes dans l'unité et sur les câbles d'interface qui peuvent choquer ou causer

des blessures graves. Lorsqu'il est équipé de modules de sonnerie, des tensions dangereuses seront présentes sur les

connecteurs de sortie de la sonnerie.

• Utiliser les précautions suivantes en plus des procédures appropriées de formation et de sécurité d'emploi:

• n'utiliser que des outils correctement isolés.

• Enlevez tous les objets métalliques (porte-clés, lunettes, bagues, montres ou autres bijoux).

• suivez les procédures de lock out tag out (LOTO): client spécifié, spécifique au site ou général selon le cas.

Débranchez toutes les entrées d'alimentation avant d'entretenir l'équipement. Vérifiez l'alimentation de plusieurs

entrées.

• Portez des lunettes de sécurité.

• respectez les exigences relatives aux équipements de protection individuelle: client spécifié, spécifique au site ou

général selon le cas.

• tester les circuits avant de les toucher.

• être conscient des dangers potentiels avant d'entretenir l'équipement.

• identifier les potentiels électriques dangereux exposés sur les connecteurs, le câblage, etc.

• Évitez de contacter les circuits lors du démontage ou du remplacement des couvercles.

• utilisez une sangle ESD personnelle lors de l'accès ou de la suppression de composants électroniques.

• Le personnel équipé de dispositifs médicaux électroniques doit être conscient que la proximité des systèmes de

distribution et d'alimentation en courant continu, y compris les piles et les câbles, généralement dans les salles de

télécommunication, peut affecter les appareils électroniques médicaux, tels que les stimulateurs cardiaques. Les

effets diminuent avec la distance.

• N'installez pas cet équipement sur des surfaces combustibles.

• Règles et règlements-respectez toutes les règles et réglementations nationales et locales lors de la réalisation de

connexions sur le terrain.

• Connecteurs de compression

• U. S. ou installations du Canada-utiliser des connecteurs de compression répertoriés/certifiés pour mettre fin

aux conducteurs de fil de champ répertoriés/certifiés.

• toutes les installations-appliquer le connecteur approprié au conducteur de taille correct tel que spécifié par le

fabricant du connecteur, en utilisant uniquement l'outillage recommandé ou approuvé par le fabricant du

connecteur pour ce connecteur.

• Fixation de la connexion électrique: Serrez les valeurs spécifiées sur les étiquettes ou dans la documentation du produit.

• Robe de câble-robe pour éviter d'endommager les conducteurs et une contrainte excessive sur les connecteurs.

• Disjoncteurs et fusibles

• n'utiliser que ceux spécifiés dans le Guide de commande de l'équipement.

• la taille exigée par le National Electric Code (NEC) et/ou les codes locaux.

• Limites de sécurité testées-référez-vous aux cotes de l'équipement pour assurer que le courant ne dépasse pas: charge

continue (Liste 1)-60% du degré de protection

• Charge maximale (liste 2-typiquement fin de décharge)-80% du degré de protection.

• fusibles de type GMT-Utilisez uniquement des fusibles fournis avec des capuchons de sécurité.

• Conducteurs câblés-suivez tout le code national de l'électricité (NEC) et les règles et réglementations locales.

• indice d'isolation: 90 ° c minimum; 105 ° c (minimum) si interne aux armoires d'équipement fermées.

• la taille des conducteurs câblés de champ AC avec une ampacité de 75 ° c (NEC) égale ou supérieure à leur indice

de disjoncteur de la carte de panneau.

• la taille des conducteurs de champ DC avec une ampacité de 90 ° c (NEC) égale ou supérieure à la puissance

nominale du disjoncteur/fusible.

• Déconnexion/protection d'entrée AC et DC-fournissez des dispositifs accessibles pour enlever la puissance d'entrée en cas

d'urgence.

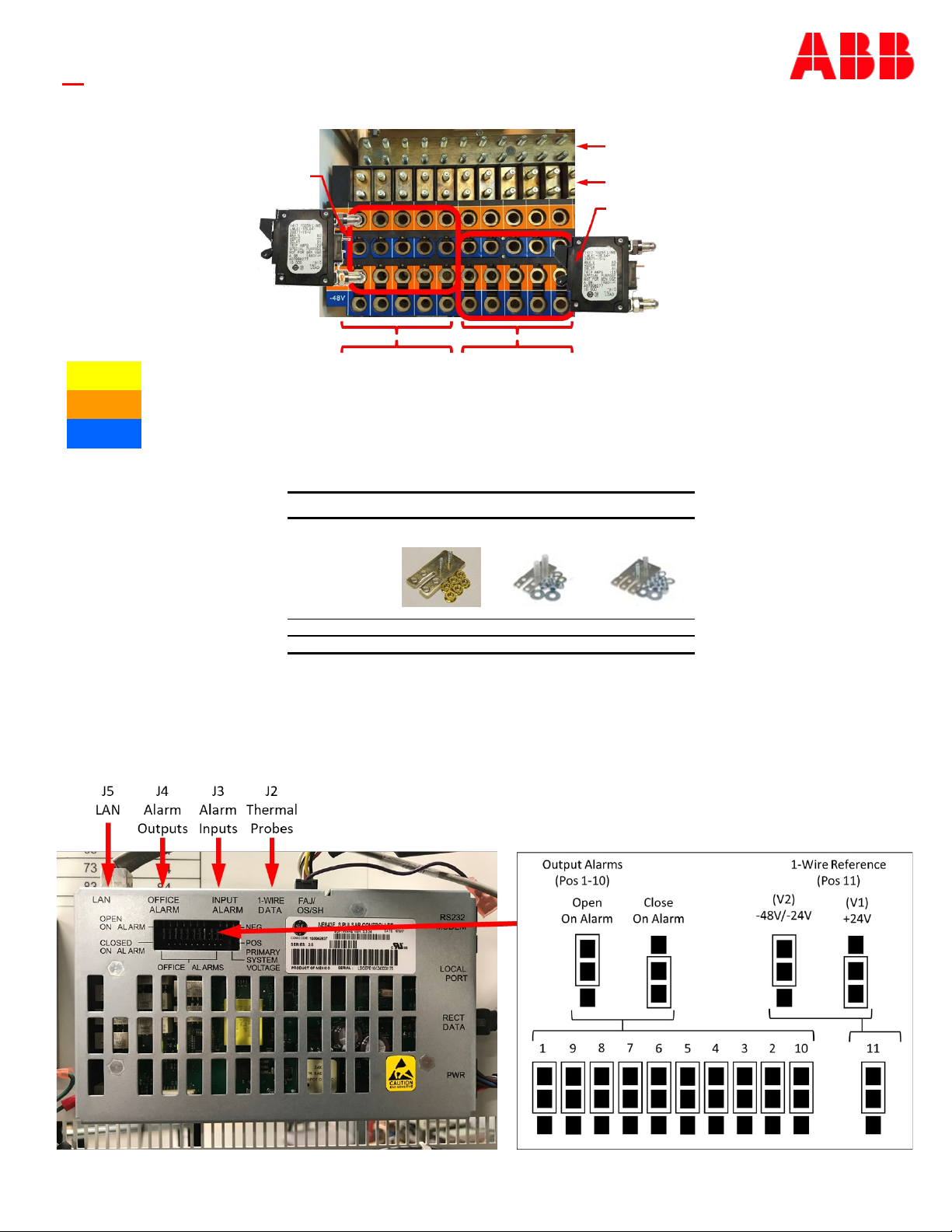

• Signaux d'alarme-fournir une protection de limitation de courant externe. Note 60V, 0.5 A sauf indication contraire.

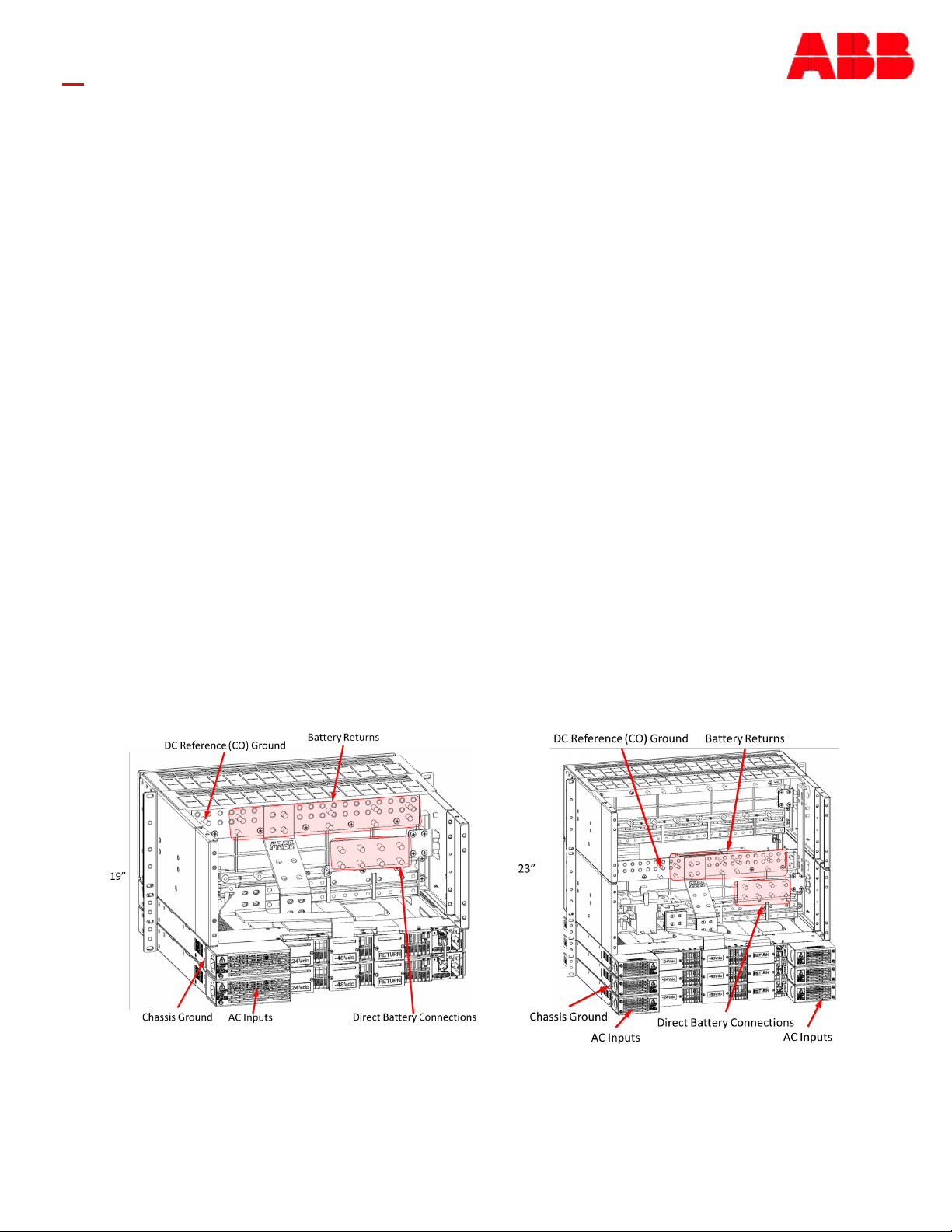

• Mise à la terre-raccorder le châssis de l'équipement directement à la terre. Dans les armoires d'équipement fermées,

raccorder au bus de masse du service AC de l'armoire. Dans les cabanes, les coffres et les bureaux centraux se connectent

au réseau de liaison du système.

QUICK START GUIDE