Page 6

© 2020 ABB. All rights reserved.

QUICK START GUIDE

Order Codes Descriptions

CC109142980 QS873A Thermal Probe

CC848817024 B 10’ controller to thermal probe wireset

CC109157434 B 20’ controller to thermal probe wireset

CC848822560 C 1’ thermal probe to thermal probe wireset

848719803 C 5’ thermal probe to thermal probe wireset

CC848822321 C 10’ thermal probe to thermal probe wireset

Order Codes Descriptions

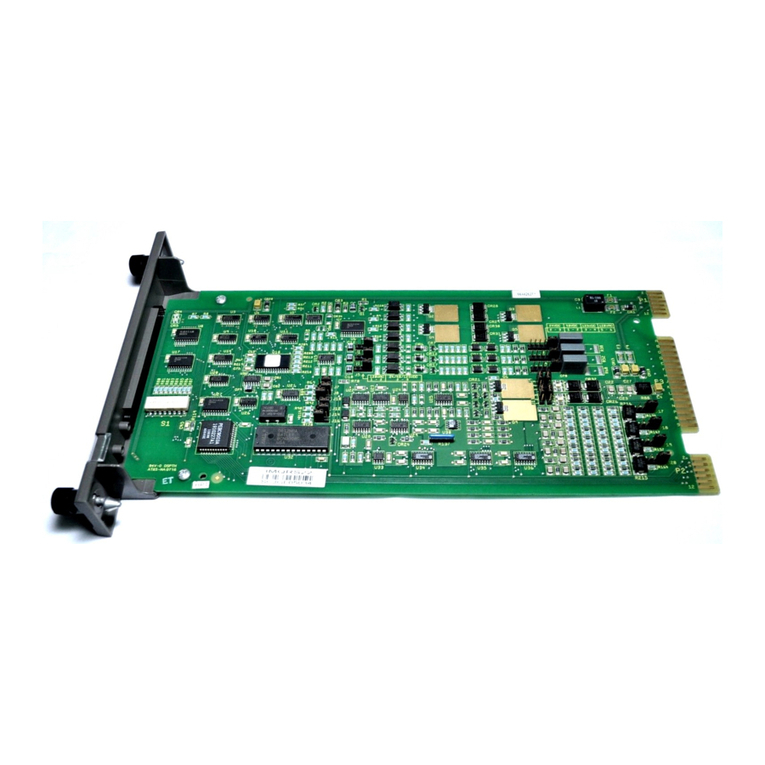

108958422 ES771A Voltage Monitor Card

CC848791517 D 2 ½’ ES771A to probe wireset

CC848797290 D 6’ ES771A to probe wireset

848719829 D 10’ ES771A to probe wireset

CC848791500 G 4’ ES771A to ES771A or controller wireset

848652947 G 10’ ES771A to ES771A or controller wireset

Information: Controller Connections

Alarm Outputs

Alarm relays are factory set to Open On

Alarm. If Close On Alarm is desired adjust

controller alarm jumpers. See diagram in

step 5 for the location of the controller

alarm jumpers. Connector J4 provides

access to the primary customer alarm

outputs. J4 is a 20-pin latching connector.

Alarm Output Cables

CC848890137 5 ft.

CC109157442 15ft

CC848817635 50 ft

CC848817643 150 ft

Standard Controller Alarm Output

Defaults Pin Color

Option 1

Color

Option

2

PCR Power Critical 1BL BL

PCR_C Power Critical_C 11 WBL/BK

PMJ Power Major 2OO

PMJ_C Power Major_C 12 WO/BK

PMN Power Minor 3GG

PMN_C Power Minor_C 13 WG/BK

R1 Battery On Discharge 4BR W

R1_C Battery On Discharge_C (BD_C) 14 WW/BK

R2 Very Low Voltage (VLV) 5SBK

R2_C Very Low Voltage_C (VLV_C) 15 WBK/W

R3 Fuse Alarm Major (FAJ) 6BL BL/W

R3_C Fuse Alarm Major_C (FAJ_C) 16 RBL/R

R4 AC Fail (ACF) 7OO/R

R4_C AC Fail_C (ACF_C) 17 RR

R5 Rectifier Fail (RFA) 8GG/W

R5_C Rectifier Fail_C (RFA_C) 18 RR/G

R6 Mult. Rectifier Fail (MRFA) 9BR W/R

R6_C Mult. Rectifier Fail_C (MRFA_C) 19 RR/W

R7 High Voltage (HV) 10 SBK/R

R7_C High Voltage_C (HV_C) 20 RR/BK

Information: Battery Monitoring Connections - cables

Temperature Measurement Temperature and Voltage Measurement

Alarm Inputs

Default alarm descriptions may be

changed as needed using web pages or

Easyview2.

J3 is a 10-pin latching connector.

Standard Controller Alarm Input Defaults J3 Pin Color

Air Con Fail 1BK

Air Con Fail_Return 8V

Door Open 2BR

Door Open_Return 8V

Aux PMJ Input 3R

Battery Test/GSTR 4O

Battery Test_Return 9S

EPO 5Y

EPO_Return 10 W

Hi ext. Temp. 6G

Hi ext. Temp._Return 8V

Low ext. Temp. 7BL

Low ext. Temp._Return 8V

Alarm Input Cables

CC848890153 5 ft.

CC848865980 15ft

CC848817651 50 ft

CC848817668 150 ft