Tel: (888) 552-6467 Fax: (800) 316-4515 www.tnb.com

Pictogram Sign for Hazardous Locations

2/4

02/15 750.1593 Rev. B

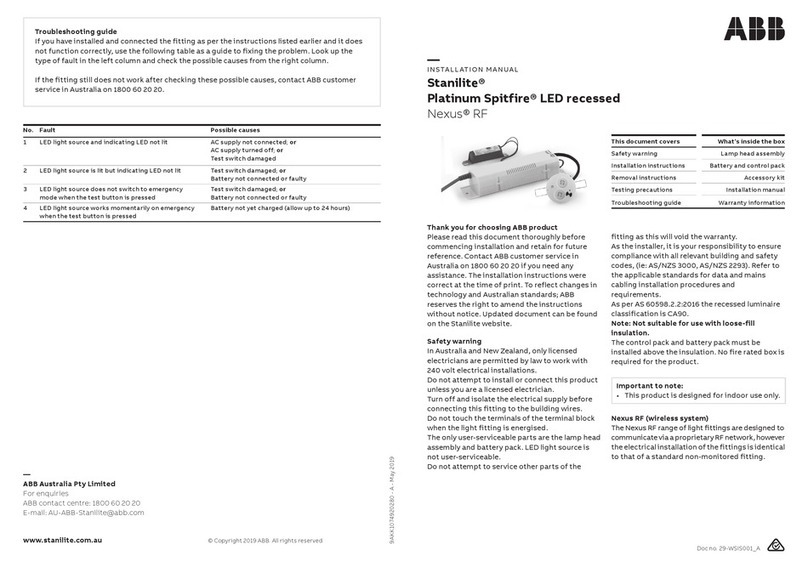

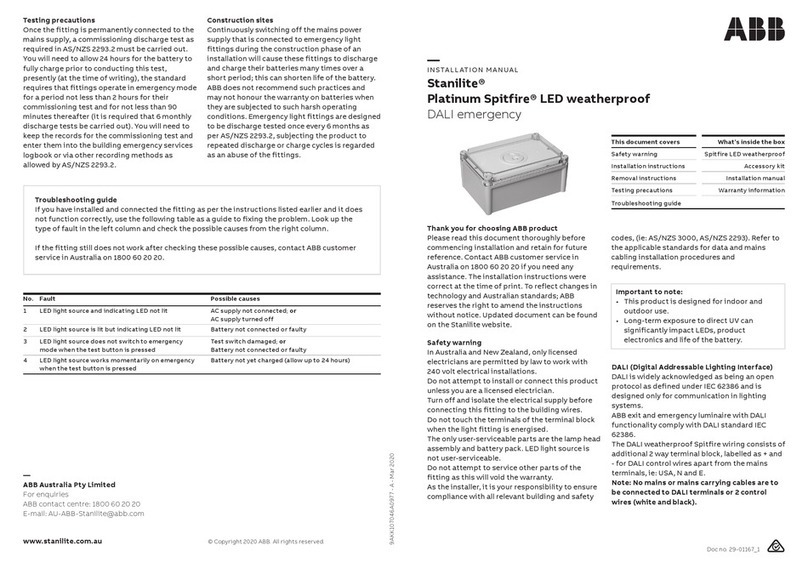

Ceiling Mount (Figure 1)

a. Remove junction box assembly from carton. Remove junction

box cover from junction box assembly and retain securement

screw.

b. Install junction box and route ACcircuit wires into the junctionbox

and leave 6” of wire length.

c. Remove lens, two pictogram panels and the opal diffuser on the

front of the unit (use the supplied bit to remove the tamper-proof

screws).

d. In order to access the knockouts of the frame, remove the 4

screw(s) holding the frame insert to the frame and separate them

(see Figure 2).

e. Ensure that the retaining screw is accessible (see Figure 1, Part

No. 13). Usethe screws fromthe junction boxto secure thecover

to the junction box.

f. Remove the left knockout on top of the frame. Determine which

holes in the frame will be used for mounting (see Figure 1).

Support frame with two blocks of wood, maximum one inch apart.

Strike knockouts with a hammer and screwdriver. Clear holes of

burrs to allow proper assembly of nipple/wire assembly.

g. Thread nipple/wire assembly into the frame.

h. Secure junction box cover to the frame using the provided nut.

i. Reassemble the frame insert inside the frame.

Wall Mount (Single Face Model Only)

a. Remove junction box assembly from carton. Remove junction

box cover from junction box assembly, install hub on junction box

and retain securement screw.

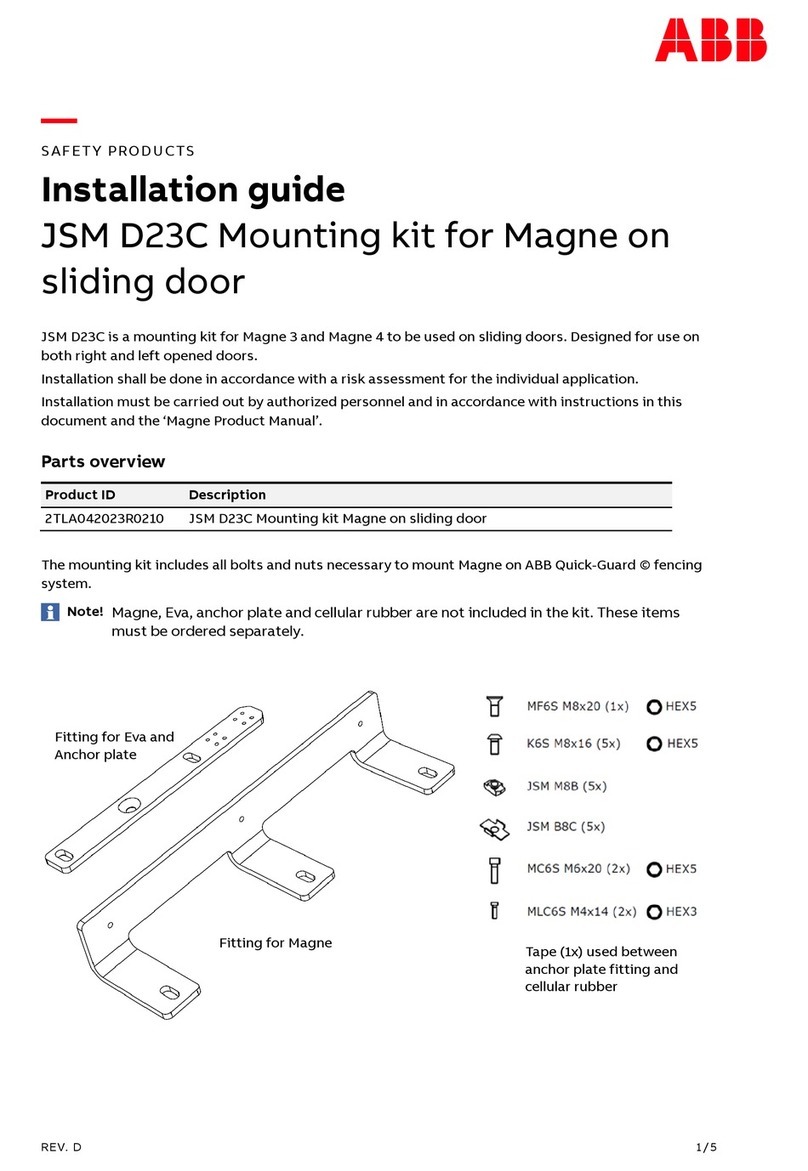

b. Remove the backplate (9) from the packaging. Determine the

proper knockouts to remove for mounting to the junction box (see

Figure 3).

c. Support area around knockouts with two blocks of wood. Strike

knockouts from the inside with a hammer and a screwdriver.

d. Reinstall the backplate to the frame using the 6 tamper-proof

screws (use the supplied bit).

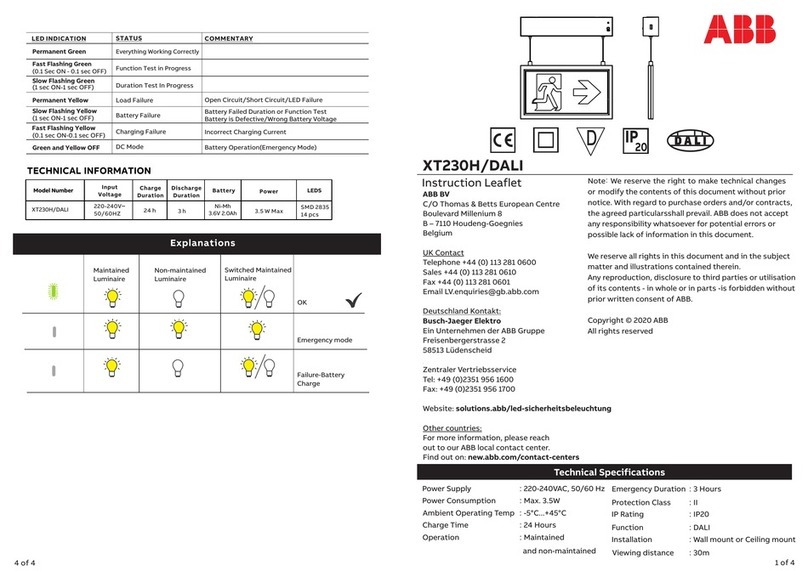

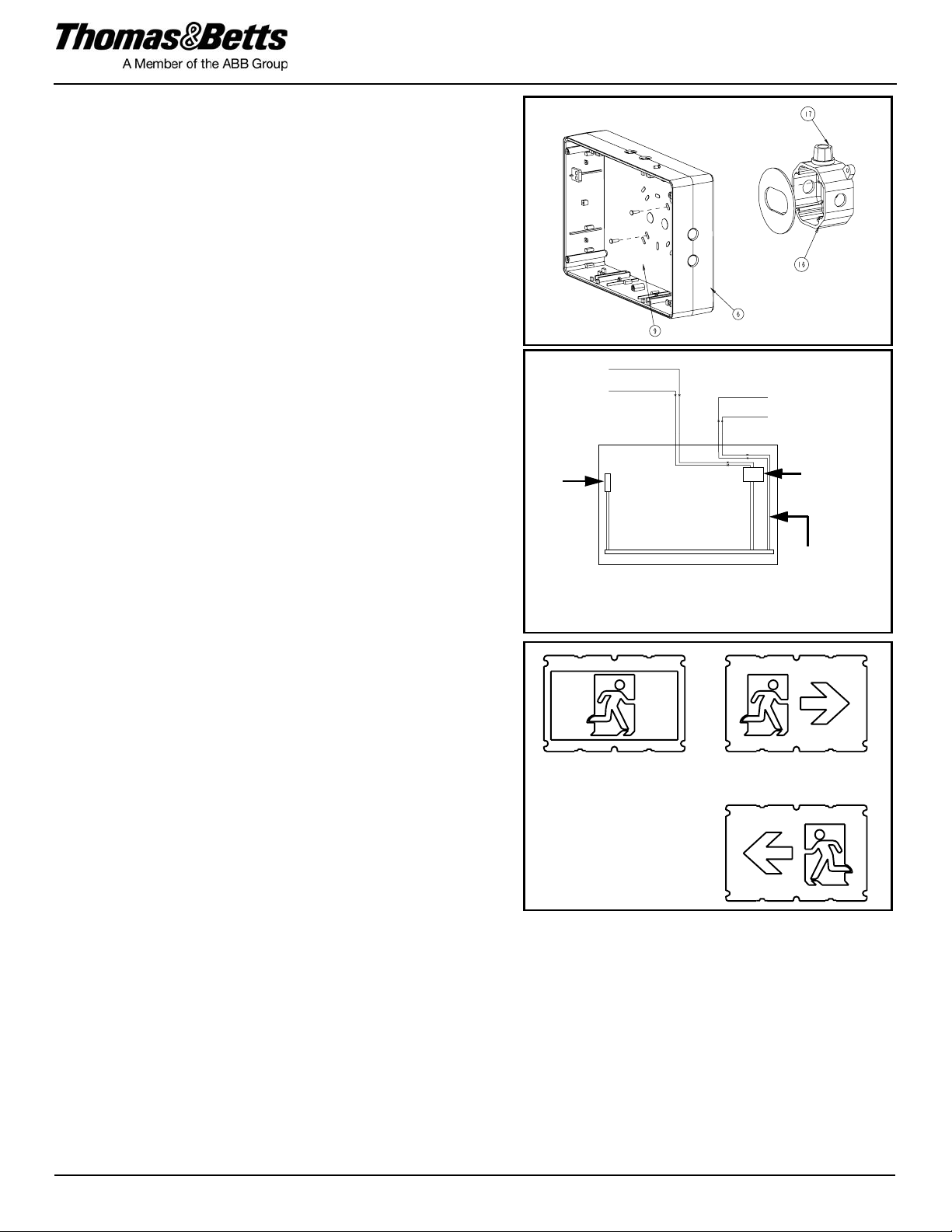

2. Electrical connections: Connect one end to the leads inside the

enclosure and the other end to AC line voltage inside the junction

box. Connect the white lead to neutral and the purple lead to AC line

voltage (the input is universal ). (See Figure 4). Connect the

ground(green wire) to the junction box.

Optional: For AC models with DC remote power, one end connects

to the LED-STRIP leads inside theenclosure and the other endto the

DC input inside the junction box. Connect the redlead to the positive

and the blue lead to the negative of the remote DC input

(see Figure 4).

For ceiling mount: Mount the frame and junction box cover

assembly to junction box by using the provided securement screw.

For wall mount: Attach the frame (6) to the junction box, using the

junction box supplied screws. Install 2 stem washers to ensure

bonding.

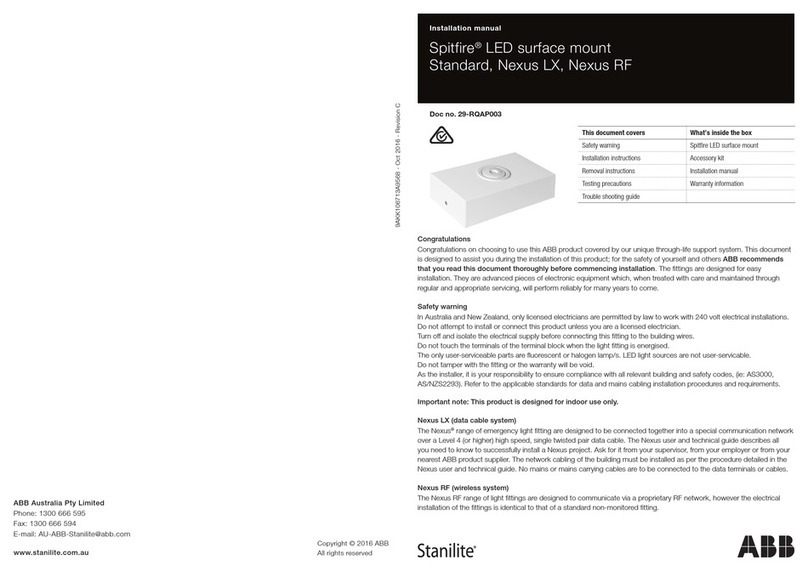

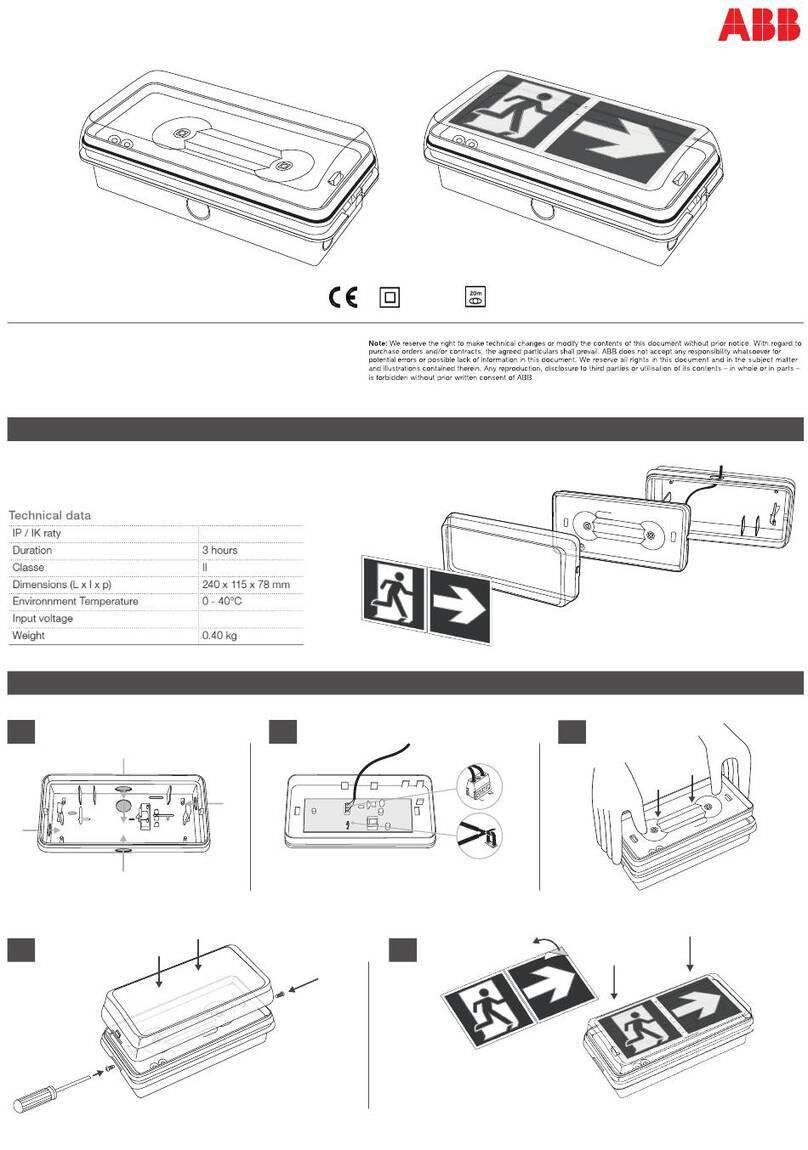

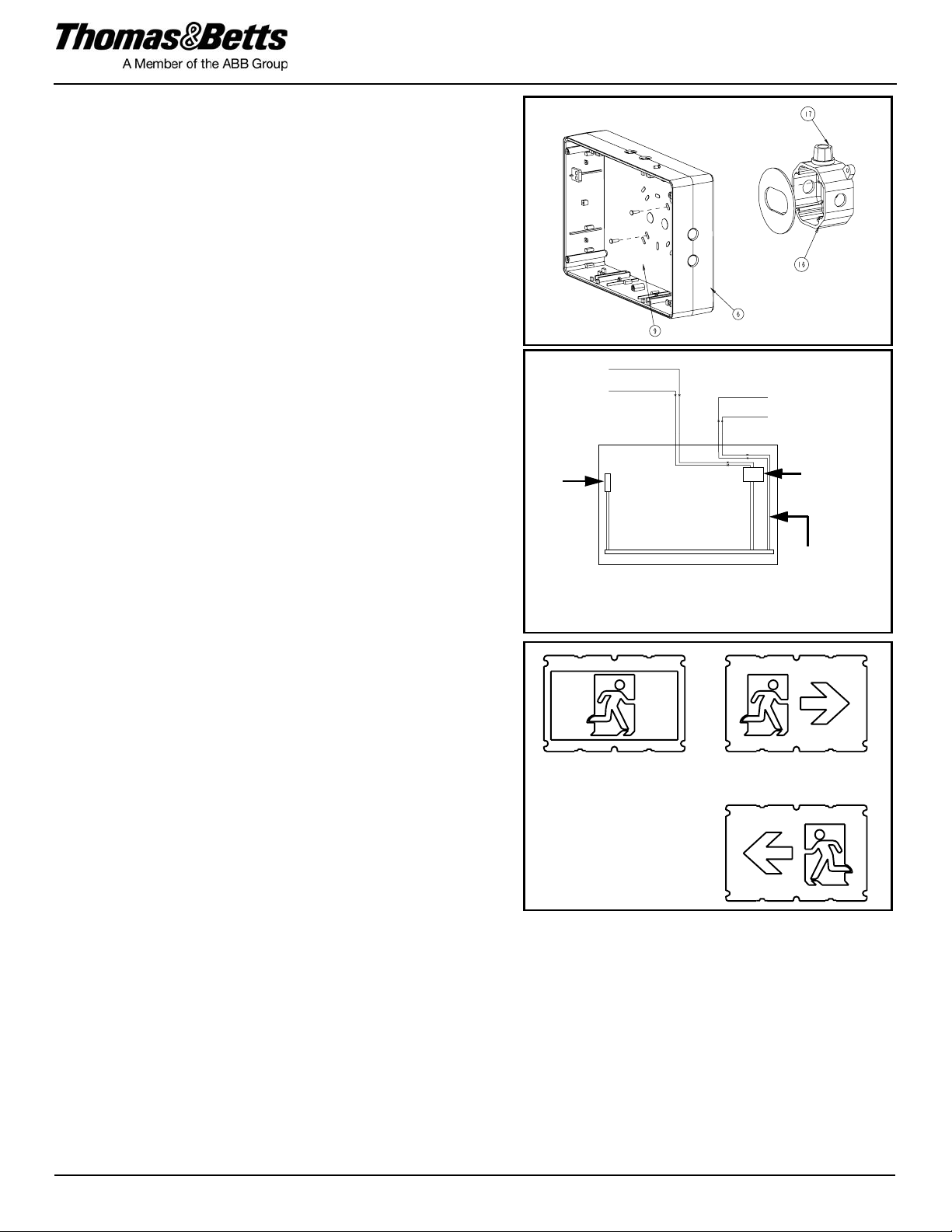

3. Select the desired pictogram panel and install it with the opal diffuser

behind. The pictogram panel without arrow shall be installed facing

right (see Figure 5).

4. Install the lens by using the 6 tamper-proof screws.The o-ring has to

be installed on the center screws between the lens and the frame as

shown in figure 1.

The tamper-proof screws should be equally torqued to

approximately 10 - 15 in-lbs (1.1 - 1.7 N-m).

5. Energize AC. Sign will illuminate.

Figure 3

Figure 4

Purple- AC

White - Neutral Red + DC

Blue - DC

Battery

(Self-Powered

Transformer

DC supply

only)

Primary wire connections must be isolated from charger.

Figure 5

pictogram panel with arrow

pictogram panel

Install the panel with Flip the panel

the person going to the right for arrow left (below)