2 TTF300 FIELD-MOUNT TEMPERATURE TRANSMITTER | OI/TTF300-EN REV. I

Table of contents

1Safety..........................................................................4

General information and instructions..................................4

Warnings....................................................................................4

Intended use .............................................................................5

Improper use.............................................................................5

Warranty provisions.................................................................5

Cyber security disclaimer .......................................................5

Software downloads ...............................................................5

Manufacturer’s address ..........................................................5

Service address.........................................................................5

2Use in potentially explosive atmospheres in

accordance with ATEX and IECEx ............................6

Ex marking.................................................................................6

Transmitter ..........................................................................6

LCD indicator ....................................................................... 7

Temperature data ....................................................................8

Transmitter ..........................................................................8

LCD indicator .......................................................................8

Electrical data ...........................................................................8

Transmitter ..........................................................................8

LCD indicator .......................................................................9

Installation instructions........................................................10

ATEX / IECEx / EAC-Ex .....................................................10

Cable entries ......................................................................10

Electrical connections ...................................................... 11

Commissioning.......................................................................16

Operating instructions.......................................................... 17

Damage to the ‘Flameproof (enclosure)– Ex d’ type of

protection........................................................................... 17

Protection against electrostatic discharges................ 17

Repair ....................................................................................... 17

3Use in potentially explosive atmospheres in

accordance with cFMus, FM and CSA .................... 18

Transmitter Ex marking cFMus ........................................... 18

Transmitter Ex marking FM / CSA ...................................... 18

LCD indicator Ex marking.....................................................19

Installation instructions........................................................20

Electrical connections ......................................................20

Commissioning.......................................................................20

Operating instructions..........................................................20

Adverse effect on the ‘Explosionproof – XP’ type of

protection...........................................................................20

Protection against electrostatic discharges................20

Repair ....................................................................................... 21

4Design and function ................................................ 22

Input functionality .................................................................22

Sensor redundancy ........................................................... 22

Sensor drift monitoring ...................................................24

Sensor error adjustment in accordance with Callendar-

Van Dusen ...........................................................................24

5Product identification.............................................25

Name plate.............................................................................. 25

Explosion protection marking for devices with one

type of protection............................................................. 25

Explosion protection marking for devices with several

types of protection........................................................... 26

6Transport and storage ............................................27

Inspection ............................................................................... 27

Transporting the device ....................................................... 27

Storing the device.................................................................. 27

Ambient conditions.......................................................... 27

Returning devices .................................................................. 27

7Installation................................................................27

Ambient conditions............................................................... 27

Mounting................................................................................. 28

Opening and closing the housing....................................... 28

Rotating the LCD indicator.................................................. 29

8Electrical connections ............................................ 29

Safety instructions ................................................................ 29

Protection of the transmitter from damage caused by

highly energetic electrical interferences ...........................30

Suitable protective measures......................................... 30

Conductor material ............................................................... 30

Power supply cable........................................................... 30

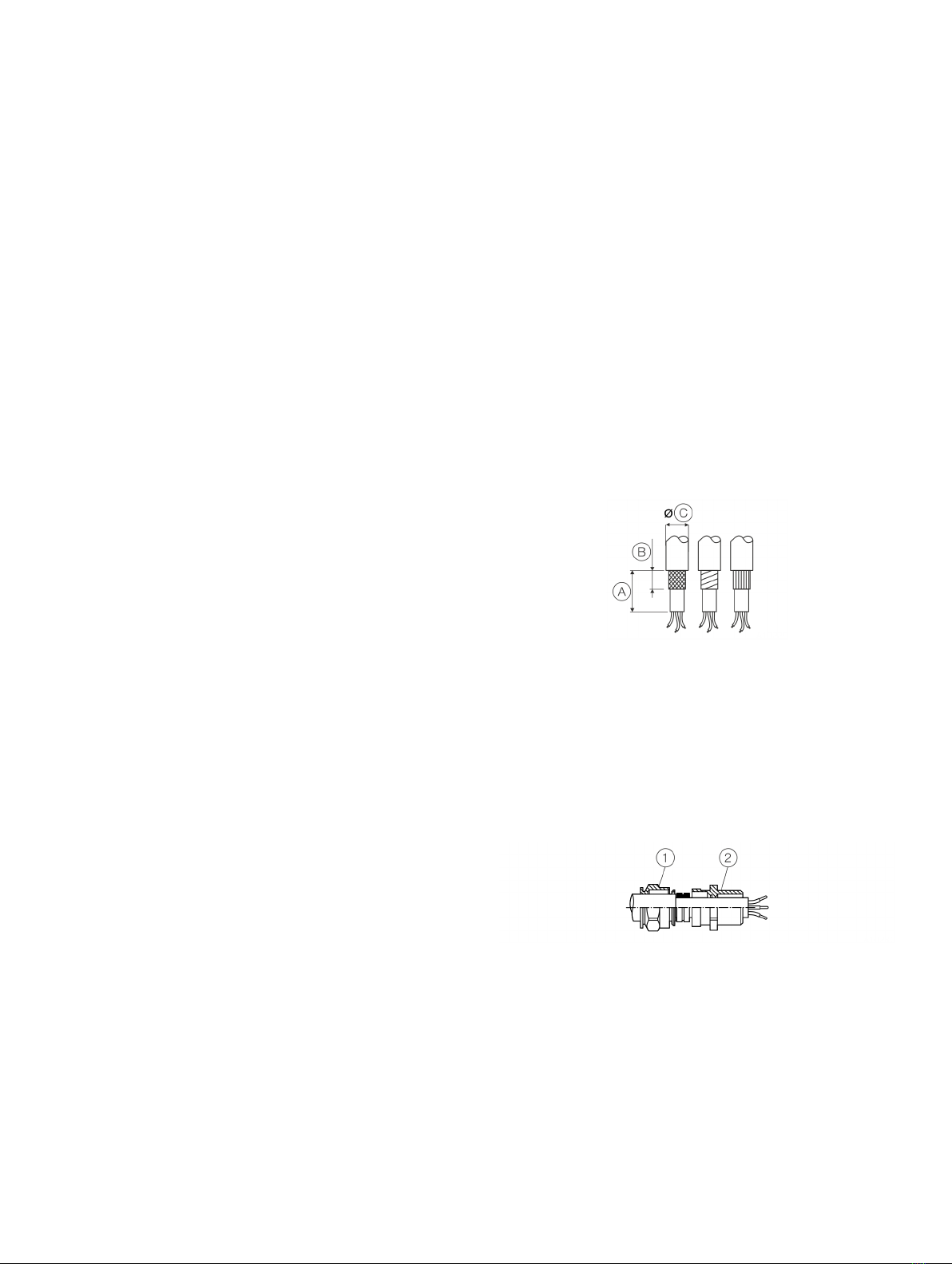

Cable glands ...........................................................................30

Shielding of the sensor connecting cable..........................31

Recommended shielding / grounding ...........................31

Additional examples for shielding / grounding .......... 32

Terminal assignment ............................................................ 34

Resistance thermometers (RTD) / resistors

(potentiometer) ................................................................ 34

Thermocouples / voltages and resistance

thermometers (RTD) / thermocouple combinations. 35

Terminal for sensor connection cable ............................... 36

Electrical data for inputs and outputs............................... 37

Input - resistance thermometer / resistances ............ 37

Input - thermocouples / voltages.................................. 37

Functionality input ........................................................... 37

Output – HART®................................................................. 38

Output – PROFIBUS PA® .................................................. 38

Output – FOUNDATION Fieldbus® ................................. 39

Power supply ..................................................................... 39

Power supply – HART® ..................................................... 39

Power supply – PROFIBUS / FOUNDATION Fieldbus .40