4266 DDS HART | PRESSURE TRANSMITTERS | OI/266DDS-EN REV. B

1 Safety

General safety information

The “Safety” section provides an overview of the safety aspects

to be observed for operation of the device.

The device has been constructed in accordance with the state

of the art and is operationally safe. It has been tested and left

the factory in perfect working conditions. The information in

the manual, as well as the applicable documentation and

certificates, must be observed and followed in order to

maintain this condition throughout the period of operation.

Full compliance with the general safety requirements must be

observed during operation of the device. In addition to the

general information, the individual sections in the manual

contain descriptions of processes or procedural instructions

with specific safety information.

Only by observing all of the safety information can you reduce

to the minimum the risk of hazards for personnel and/or

environment. These instructions are intended as an overview

and do not contain detailed information on all available models

or every conceivable event that may occur during setup,

operation, and maintenance work.

For additional information, or in the event of specific problems

not covered in detail by these operating instructions, please

contact the manufacturer. In addition, ABB declares that the

contents of this manual are not part of any prior or existing

agreements, commitments, or legal relationships; nor are they

intended to amend these.

All obligations of ABB arise from the conditions of the relevant

sales agreement, which also contains the solely binding

warranty regulations in full. These contractual warranty

provisions are neither extended nor limited by the information

provided in this manual.

Only qualified and authorized specialist personnel should

be charged with installation, electrical connection,

commissioning, and maintenance of the transmitter.

Qualified personnel are persons who have experience in

installation, electrical wiring connection, commissioning, and

operation of the transmitter or similar devices, and hold the

necessary qualifications such as:

• Training or instruction, i.e., authorization to operate and

maintain devices or systems according to safety

engineering standards for electrical circuits, high

pressures, and aggressive media

• Training or instruction in accordance with safety

engineering standards regarding maintenance and use of

adequate safety systems.

For safety reasons, ABB draws your attention to the fact that

only sufficiently insulated tools conforming to EN 60900 may

be used.

Since the transmitter may form part of a safety chain, we

recommend replacing the device immediately if any defects

are detected. In case of use in Hazardous Area non sparking

tools only must be employed.

In addition, you must observe the relevant safety regulations

regarding the installation and operation of electrical systems,

and the relevant standards, regulations and guidelines about

explosion protection.

The device can be operated at high levels of pressure and

with aggressive process media. As a result, serious injury or

significant property damage may occur if this device is

operated incorrectly.

Improper use

It is prohibited to use the device for the following purposes:

• As a climbing aid, e.g., for mounting purposes.

• As a support for external loads, e.g., as a support for pipes.

• Adding material, e.g., by painting over the name plate or

welding/soldering on parts.

• Removing material, e.g., by drilling the housing.

Repairs, alterations and enhancements, or the installation of

replacement parts are only permissible as far as these are

described in the manual. Approval by ABB must be requested

for any activities beyond this scope. Repairs performed by

ABB-authorized centers are excluded from this.

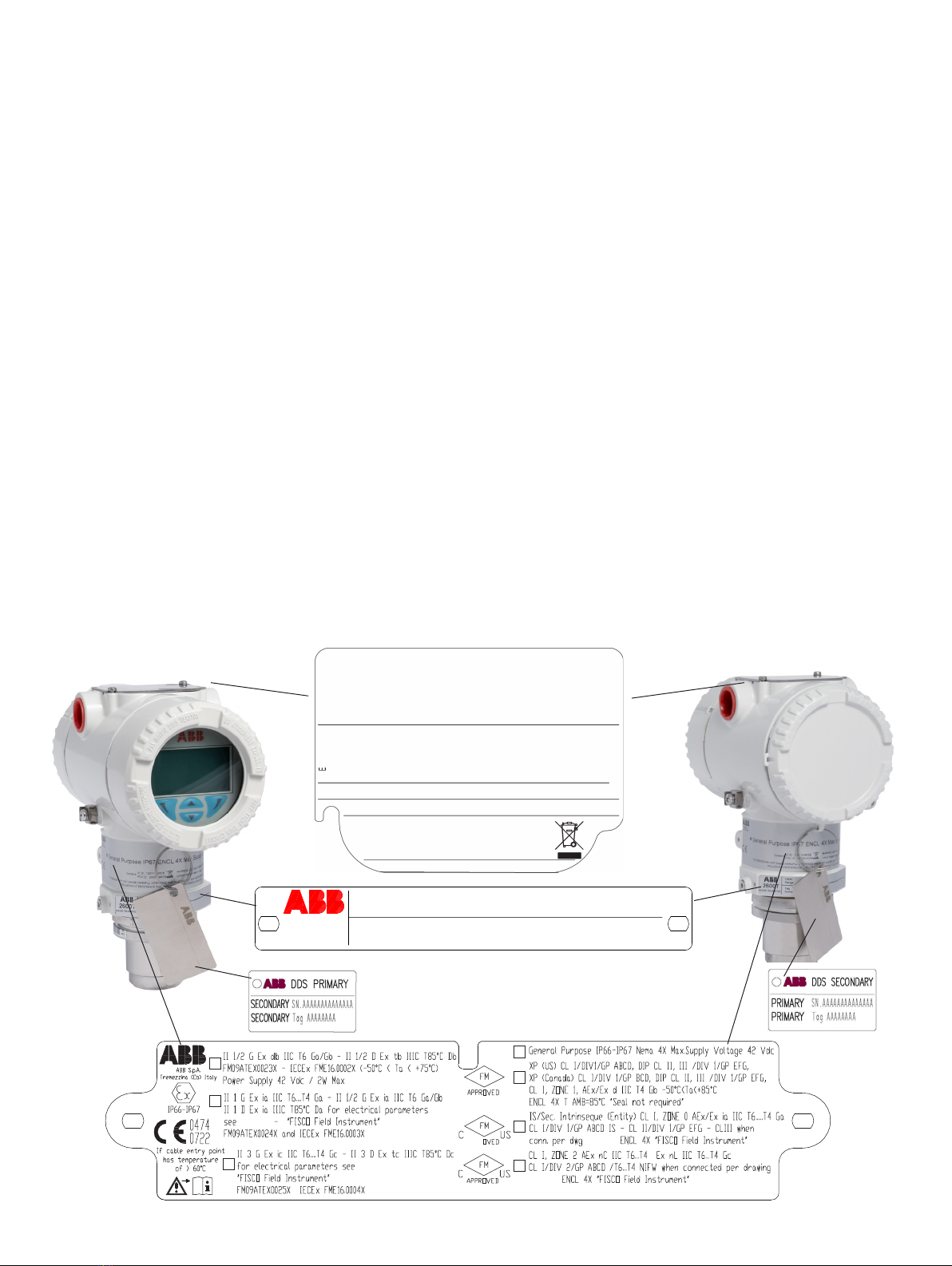

Technical limit values

The device is designed for use exclusively within the values

stated on the name plates and within the technical limit values

specified on the data sheets.

The following technical limit values must be observed:

• The Maximum Working Pressure may not be exceeded.

• The Maximum ambient operating temperature may not be

exceeded.

• The Maximum process temperature may not be exceeded.

• The enclosure method of protection type must be

observed.

Warranty provision

Using the device in a manner that does not fall within the scope

of its intended use, disregarding this manual, using

underqualified personnel, or making unauthorized alterations,

releases the manufacturer from any liability for any resulting

damage. This makes the manufacturer’s warranty null and void.

Use of instruction

Serious damage to health/risk to life.

This message indicates that an imminent risk is present.

Failure to avoid this will result in death or serious injury.

CAUTION

WARNING

DANGER