4

VITESS™ LOCKING SYSTEM

• When patent is granted, patented key

control through 2034

• Trademark Intop System restricts

unauthorized key duplication even aer

patent expires

• Available in Mortise, Rim, Key-in-Knob/Lever,

Deadbolt and 83 Series™ Locking Insert

HIGHLIGHTS OF VITESS™

TECHNICAL DETAILS

• Patent pending

• 6 locking elements

• 14mm (0.55“) core diamter

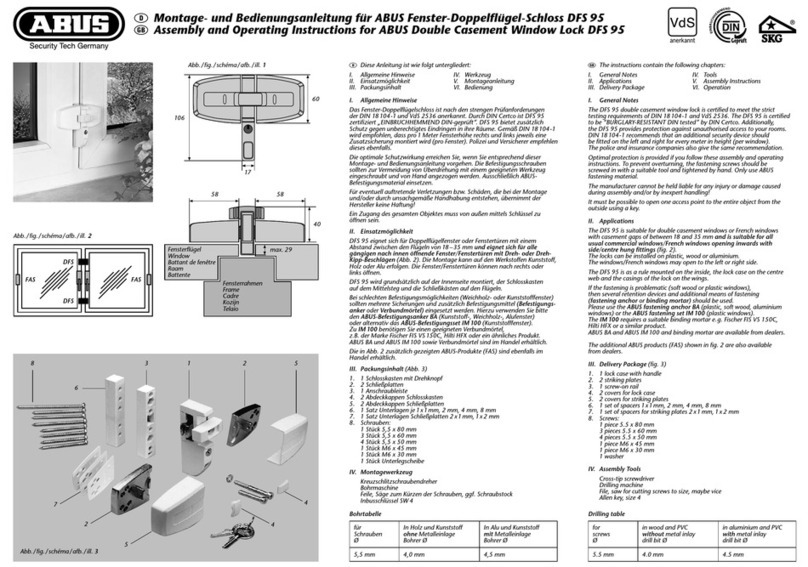

ABUS LOCKING SYSTEMS

ABUS locking systems are ideal for programs of various sizes, from small to large

master key systems. The range covers keyed alike cylinders, small and medium

master key systems, as well as large grand master key systems. If requested, the

planning and calculation of the grand master key system can be done by ABUS

Pfaenhain™.

All cylinders of ABUS Pfaenhain™ have a core diameter of 14mm (0.55“). This

increased diameter enables a very large number of combinations inside of the

cylinder, making very large and complex grand master key systems with ABUS

possible. These locking systems oer 1.5 million true key diers!

STRONG DRILL PROTECTION

• ABUS locking systems oer superior drilling protection

compared to competitors

• 4 additional hardened steel pins are inserted into the

cylinder (two per cylinder core and housing) and an additional carbide pin is inserted into the front

of both housing sides

GRAND MASTER KEY SYSTEMS WITH A GUARANTEED SUPPLY FOR THE

NEXT 20 YEARS

A grand master key system is a long-lasting investment in security. ABUS guarantees to supply needed

cylinders or single parts up to 20 years aer the creation of the grand master key system. Of course, the

system can also be extended - mechanically or electronically - at any time. For this ABUS plans 20%

extension reserve in advance.

ABUS LOCKING SYSTEMS

14mm

Patented

until 2034*

Trademark

Protection

Standard drill protection -

pins made of hardenend steel

6 locking elements

Intop System

Paracentric

precision

profile

Key cuts Intop System

Intop

System

*Patent pending, max. patent term 2034