Contents

1.0 Introduction ........................................................................................................................................................... 1

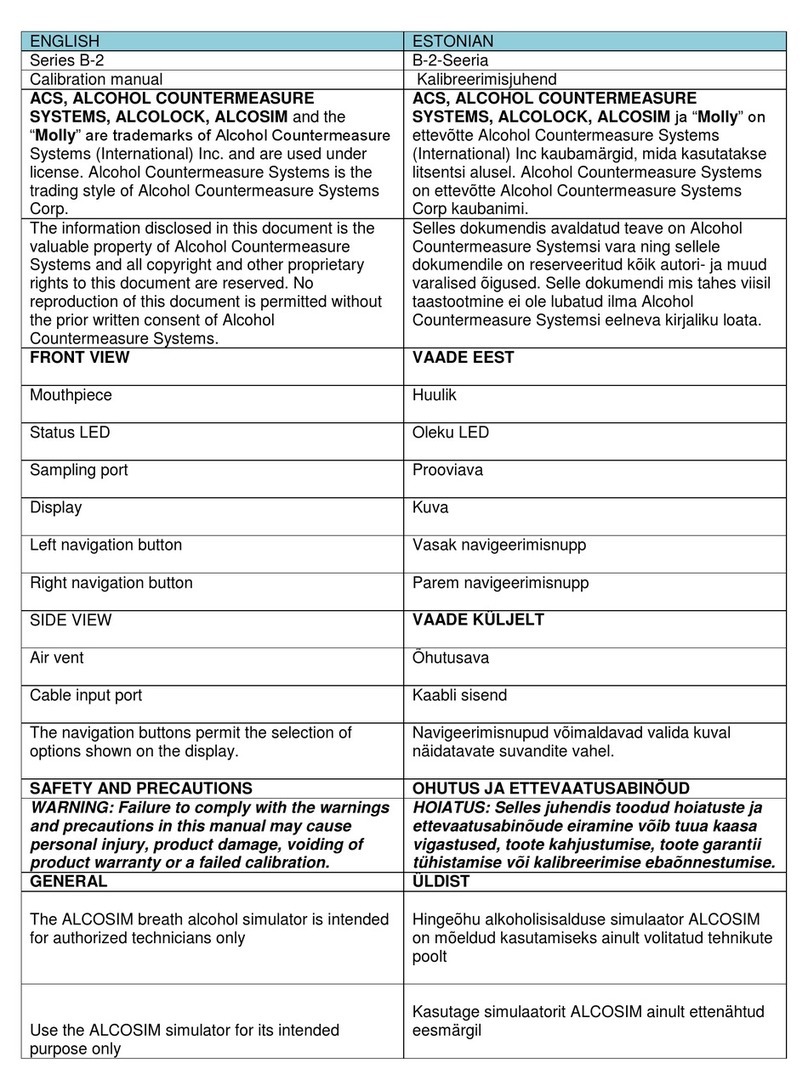

2.0 Glossary of terminology....................................................................................................................................... 2

3.0 ACS part numbers.................................................................................................................................................2

4.0 Part descriptions................................................................................................................................................... 2

4.1 Power supply ........................................................................................................................................................................2

4.2 Auto-Cal ECU .......................................................................................................................................................................2

4.3 ALCOSIM breath alcohol simulator.......................................................................................................................................2

4.4 Calibration Station (CS) ........................................................................................................................................................3

4.5 Aquarium air pump................................................................................................................................................................3

4.6 ITE software..........................................................................................................................................................................3

4.7 Alcohol reference solution.....................................................................................................................................................3

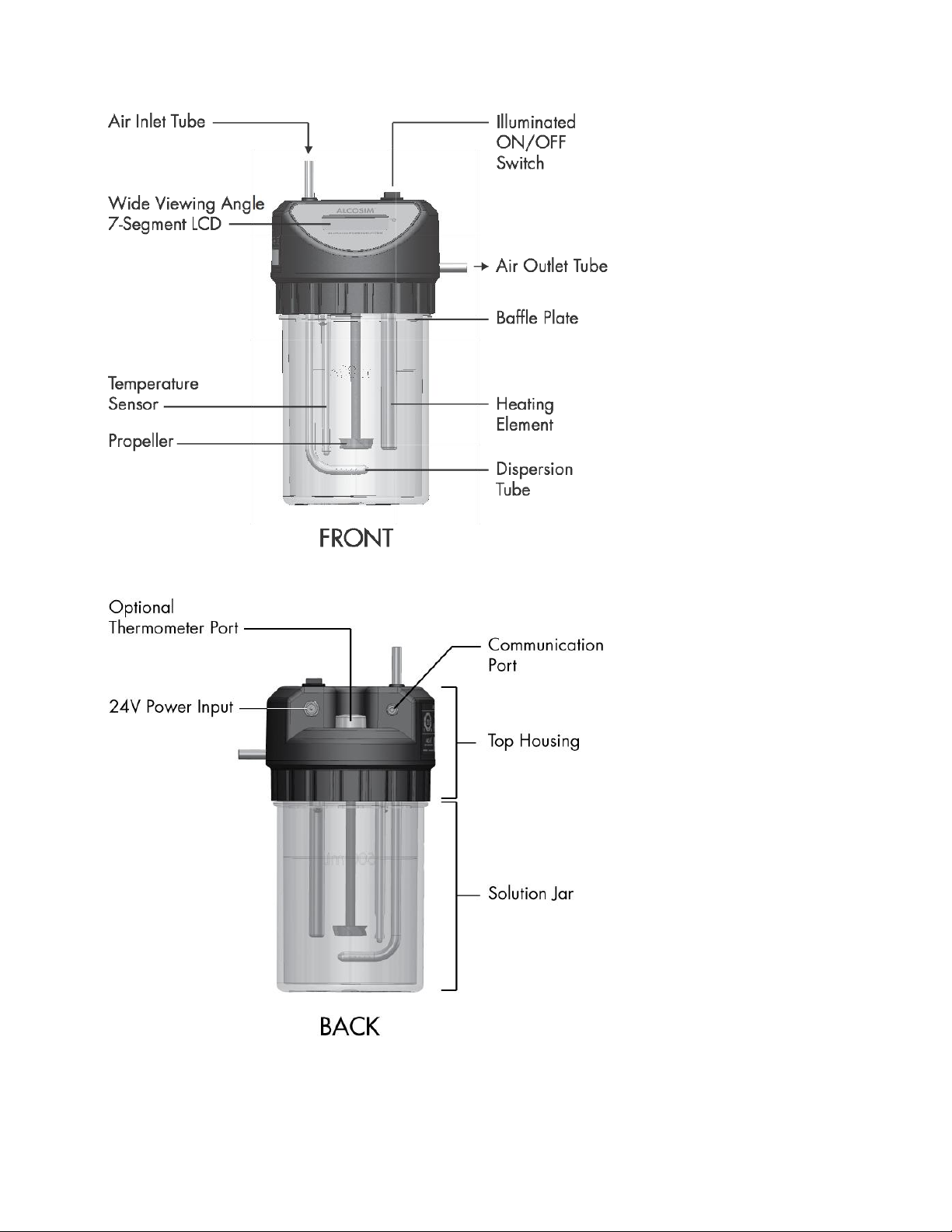

5.0 ALCOSIM breath alcohol simulator diagram......................................................................................................4

6.0 Calibration Station (CS) diagram.........................................................................................................................5

7.0 Unpacking, inspection and operating check......................................................................................................6

7.1 Inspecting the ALCOSIM simulator.......................................................................................................................................6

7.2 Inspecting the CS..................................................................................................................................................................6

7.3 Inspecting the ECU...............................................................................................................................................................6

7.4 Inspecting the aquarium air pump.........................................................................................................................................7

7.5 Inspecting the power supply..................................................................................................................................................7

8.0 Detailed operation................................................................................................................................................. 7

8.1 ALCOSIM breath alcohol simulator.......................................................................................................................................7

8.2 Functional test.....................................................................................................................................................................13

8.3 Verification process.............................................................................................................................................................14

8.4 Calibration process .............................................................................................................................................................14

8.5 Successful testing...............................................................................................................................................................14

9.0 Test memory of solution use .............................................................................................................................14

10.0 Automatic disabling............................................................................................................................................15

11.0 Resetting the internal counter (changing solution).........................................................................................15

12.0 Synchronization .................................................................................................................................................. 15

12.1 CS Read Procedure............................................................................................................................................................15

12.2 Result..................................................................................................................................................................................16

13.0 Reusing mouthpiece connectors ......................................................................................................................16

14.0 Troubleshooting..................................................................................................................................................17

14.1 ALCOSIM simulator –troubleshooting checklist.................................................................................................................17

14.2 ALCOSIM simulator –troubleshooting table.......................................................................................................................17

15.0 CS –Messages displayed .................................................................................................................................. 17

16.0 Problem statements............................................................................................................................................18