150-819-100-03 Table of Contents

HRE-819 List 1 and 2 July 9, 1998 v

TABLE OF CONTENTS

Overview ____________________________________________________________________________ 1

Enhanced Features .............................................................................................................................1

Standard Features...............................................................................................................................1

Description.........................................................................................................................................2

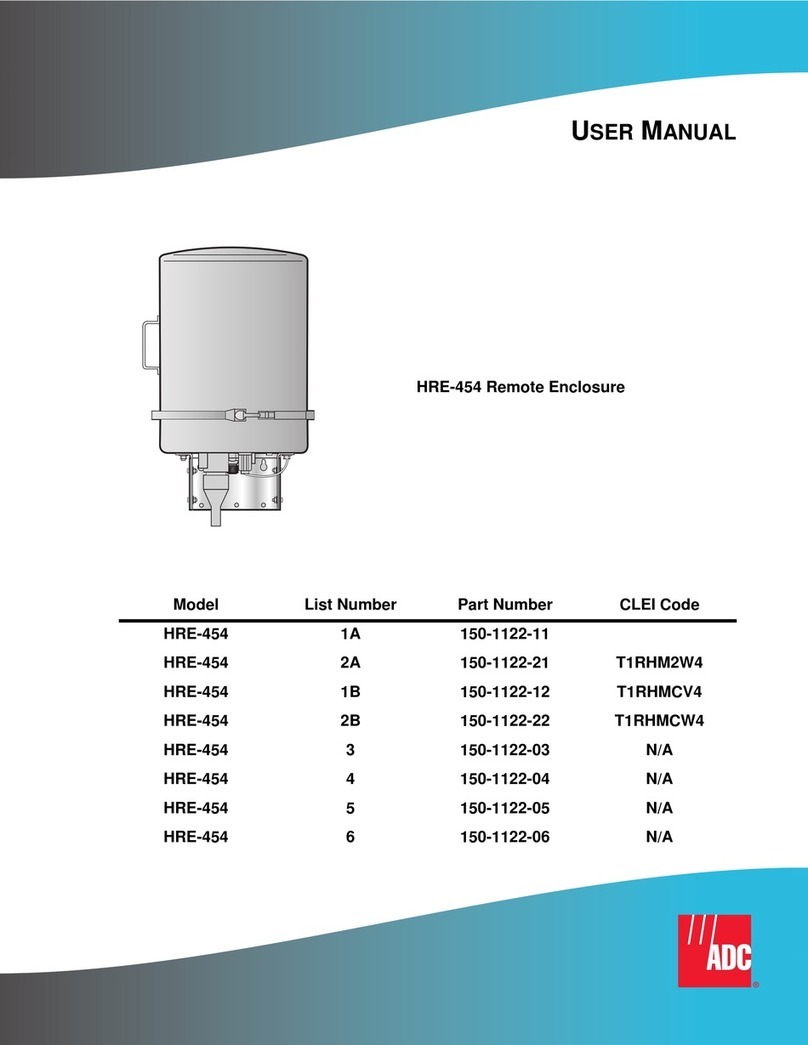

Mechanics............................................................................................................................2

Enclosure Base ....................................................................................................................4

Enclosure Housing...............................................................................................................4

Gel-filled Stub - HRE-819 List 1 Only ...............................................................................5

Air-filled Stub - HRE-819 List 2 Only................................................................................5

Pressurization.......................................................................................................................6

Air Bypass Valve ..................................................................................................6

Pressure-relief Valve and Air Stem.......................................................................7

Installation___________________________________________________________________________ 8

Unpacking..........................................................................................................................................8

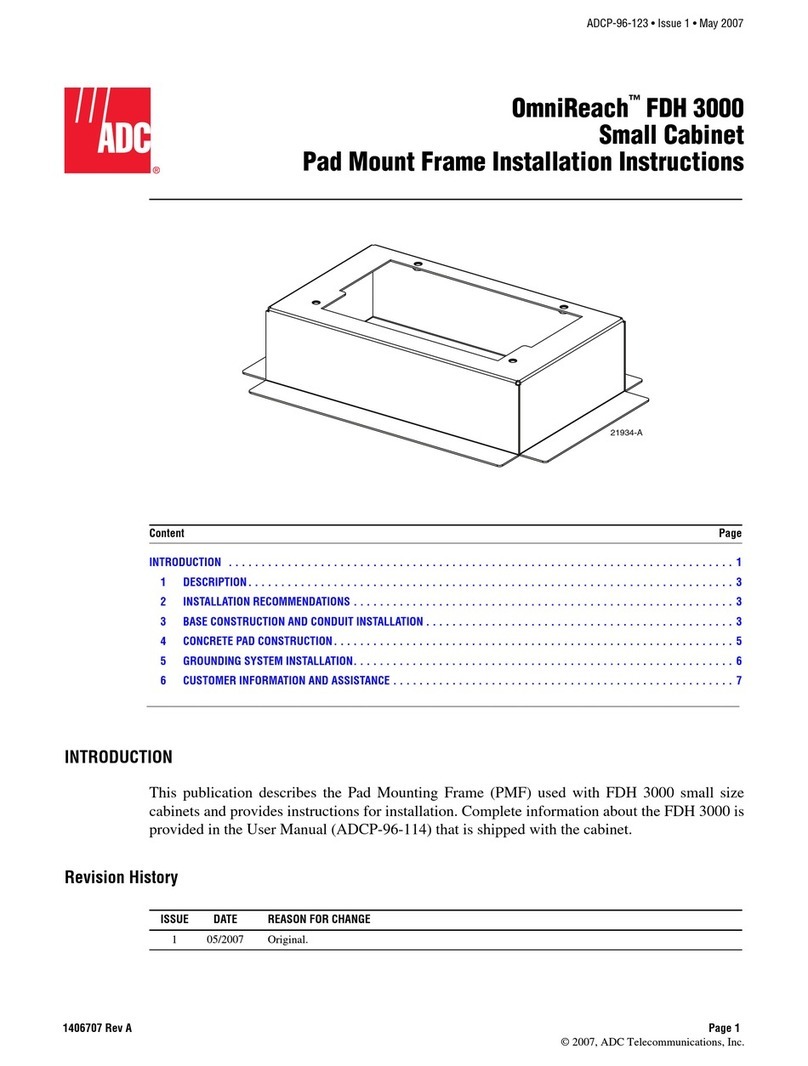

Installing the Enclosure......................................................................................................................9

Manhole Installation............................................................................................................9

Aerial Installation ..............................................................................................................10

Splicing the Stub Cable....................................................................................................................11

Order Wire .......................................................................................................................................13

Through-Connecting........................................................................................................................14

Installing Doublers and Repeaters ...................................................................................................14

Wiring................................................................................................................................15

General Deployment Rules................................................................................................17

Maintenance ________________________________________________________________________ 18

Protector Extraction .........................................................................................................................18

Protector Installation........................................................................................................................18

Removing and Replacing Broken Cover Bolts................................................................................19

Replacement Parts............................................................................................................................20

Appendix A - Specifications____________________________________________________________ 21

Environment.....................................................................................................................................21

Dimensions.......................................................................................................................................21

Appendix B - Abbreviations ___________________________________________________________ 22

Appendix C - Product Support _________________________________________________________ 23

Bar Code Label and Configuration Number....................................................................................23