Advanced Lux Intelligent LX-9400 User manual

Specifications:

Item

Specification Details

Model

LX-9400

LX-9400/D

LX-9800

Enclosure

Steel IP30, RAL 7035

Dimensions H x W x D mm

385 x 450 x 125

475 x 450 x 190

950 x 450 x 190

Weight (not including batteries)

8.6kg

12kg

23kg

Temperature

-5°to 40°C

Humidity

95 % Max

Cable Entries (20mm knockouts)

18x top, 9x top rear and 2x bottom

36x top, 9x top rear and 2x bottom

36 x top, 9 x top rear and 2 x bottom

Mains Supply

220-240V, +10%,-15%, 47–63 Hz AC,

1 A max

220-240V, +10%,-15%, 47–63 Hz AC,

1 A max

220-240V, +10%,-15%, 47–63 Hz AC,

2 A max

Safety

EN 60950-1, Class 1, Pollution Degree 2, Overvoltage category II

Battery Capacity

24V 4Ah Internal (min), 24V 12Ah

Internal (max)

24V 4Ah Internal (min), 24V 38Ah

Internal (max)

24V 4Ah Internal (min), 24V 38Ah

Internal (max) per chassis

Charging Current

2.4A

Temperature Compensated

2.4A

Temperature Compensated

2 x 2.4A

Temperature Compensated

Power Supply

Separate 24V DC, 5A Off-Line

Switched Mode

Separate 24V DC, 5A Off-Line

Switched Mode

2x Separate 24V DC, 5A Off-Line

Switched Mode

Number of Loops

1 to 4

1 to 4

2 to 8

Devices per Loop (Total)

249 (996)

249 (996)

249 (1992)

Loop Current

500mA max. per Loop

Protocols

Pulse

Auxiliary Supply Output1

24V DC, 500mA

24V DC, 500mA

2x 24V DC, 500mA

Event Log

1000 Event & Diagnostic

1000 Event & Diagnostic

2x 1000 Event & Diagnostic

Number of Zones

200 max, across 4 loops (1000 when networked)

Number of Test Groups

50

50

2x 50 (50 per chassis)

Number of Scheduled Tests

400

400

2x 400 (400 per chassis)

Integral Modem (Optional)

For connection to remote logging computer

Integral Printer (Optional)

For printing test results and warnings (automatic or manual activation)

External Printer (Optional)

For printing test results and warnings (automatic or manual activation) –RS232 Serial Interface

As our policy is one of constant product improvement the right is therefore reserved to modify product specifications without prior notice. E&OE

1

Aux supply tracks a maximum of 0.5V below battery terminal voltage when no mains supply is available

www.acornfiresecurity.com

www.acornfiresecurity.com

3

Table of Contents Page

1INTRODUCTION.............................................................................................................................................6

1.1 STANDARDS.............................................................................................................................................6

1.2 CAUTIONS AND WARNINGS .......................................................................................................................6

1.3 DESCRIPTION ...........................................................................................................................................6

1.3.1 System Features................................................................................................................................7

1.3.2 Luminaire Control / Monitor Modules.................................................................................................7

1.3.2.1 Lxp-302 Control / Monitor Module............................................................................................................7

1.3.2.2 Lxp-304 Light Monitor Module .................................................................................................................8

1.3.2.3 Lxp-110 I/O Control Module.....................................................................................................................8

1.3.2.4 Lxp-111 AC Current to Light Converter....................................................................................................8

1.4 INSTALLATION APPROVALS.......................................................................................................................9

1.4.1 Emergency Lighting Installations.......................................................................................................9

1.4.2 Wiring Regulations.............................................................................................................................9

2INSTALLATION............................................................................................................................................10

2.1 IDENTIFICATION OF PARTS ......................................................................................................................10

2.2 INSTALLING THE LX-9400 ENCLOSURE....................................................................................................10

2.2.1 Opening the Enclosure Cover..........................................................................................................10

2.2.2 Removing the Chassis.....................................................................................................................10

2.2.3 Mounting the Enclosure...................................................................................................................11

2.2.4 Remounting the Chassis..................................................................................................................11

2.2.5 Recommended Cable Routing Arrangement...................................................................................12

2.2.6 Installing Additional Option Modules................................................................................................13

2.2.6.1 Additional Signalling Line Circuits..........................................................................................................13

2.2.6.2 Removing a Loop Driver Card ...............................................................................................................13

2.2.6.3 Integral Modem Option ..........................................................................................................................14

2.2.6.4 Integral Network Option Cards...............................................................................................................14

2.2.6.5 Integral Printer Option............................................................................................................................14

2.2.6.5.1 Printer Power Supply ........................................................................................................................14

2.2.6.5.2 Printer Diagnostics............................................................................................................................15

2.2.6.5.3 Changing the Paper Roll...................................................................................................................15

2.3 WIRING INSTALLATION............................................................................................................................16

2.3.1 AC Mains Wiring ..............................................................................................................................16

2.3.1.1 Cable Gland...........................................................................................................................................16

2.3.2 Battery Installation ...........................................................................................................................17

2.3.3 Signalling Line Installation ...............................................................................................................18

2.3.3.1 General Considerations.........................................................................................................................18

2.3.3.2 Radial Wiring Format.............................................................................................................................18

2.3.3.3 Loop Wiring Format ...............................................................................................................................19

2.3.3.4 Pulse Luminaire Serial Numbers............................................................................................................19

2.3.4 Auxiliary Supply Output....................................................................................................................19

3USER OPERATION......................................................................................................................................20

3.1 CONTROLS AND INDICATIONS..................................................................................................................20

3.1.1 Graphical Display.............................................................................................................................20

3.1.2 LED Status Indicators ......................................................................................................................21

3.1.3 Control Buttons ................................................................................................................................21

3.1.4 Navigation Buttons...........................................................................................................................21

3.1.5 Number and Letter Buttons..............................................................................................................22

3.1.6 Buzzer..............................................................................................................................................22

3.2 OPERATION............................................................................................................................................22

3.2.1 Access Levels..................................................................................................................................22

3.2.1.1 Changing from Access Level 1 to 2 .......................................................................................................22

3.2.1.2 Changing from Access Level 2 to 1 .......................................................................................................23

3.2.2 Fault Condition.................................................................................................................................23

3.2.3 Alarm Condition ...............................................................................................................................24

3.2.4 Menu Functions ...............................................................................................................................25

3.2.4.1 Using the Buttons to Navigate Menus....................................................................................................25

3.2.4.1.1 Selecting Menu Options....................................................................................................................25

3.2.4.1.2 Selecting Individual Zone Numbers...................................................................................................26

3.2.5 Test..................................................................................................................................................26

3.2.5.1 Test –Lights..........................................................................................................................................27

3.2.5.1.1 Test –Lights (By Group)...................................................................................................................27

www.acornfiresecurity.com

www.acornfiresecurity.com

4

3.2.5.1.2 Test –Lights (Individually)................................................................................................................28

3.2.5.2 Test - Display ........................................................................................................................................29

3.2.5.3 Test –Print............................................................................................................................................29

3.2.6 Viewing............................................................................................................................................ 30

3.2.6.1 View - Faults..........................................................................................................................................30

3.2.6.2 View - Log .............................................................................................................................................30

3.2.6.3 View Inputs............................................................................................................................................30

3.2.6.4 View Outputs.........................................................................................................................................31

3.2.6.5 View - Panel..........................................................................................................................................32

3.2.6.6 View - Network ......................................................................................................................................33

3.2.7 Time / Date...................................................................................................................................... 33

3.2.8 Status.............................................................................................................................................. 33

3.2.9 Lock Controls.................................................................................................................................. 33

3.2.10 Print............................................................................................................................................. 34

3.2.10.1 Print –Test Results...............................................................................................................................34

3.2.10.2 Print –Log.............................................................................................................................................35

3.2.10.3 Print –Feed Paper................................................................................................................................35

3.2.10.4 Print –Stop............................................................................................................................................35

3.2.10.5 Print –Set-Up Printer ............................................................................................................................35

3.2.10.6 Printer Diagnostics ................................................................................................................................36

4PROGRAMMING......................................................................................................................................... 37

4.1 INTRODUCTION ...................................................................................................................................... 37

4.1.1 Memory Lock................................................................................................................................... 37

4.1.2 Navigating through menus.............................................................................................................. 37

4.1.3 Changing Text Descriptions............................................................................................................ 37

4.1.4 Numeric data entry.......................................................................................................................... 38

4.2 RECOMMENDED PROGRAMMING PROCEDURE......................................................................................... 39

4.3 LEVEL 3MENU FUNCTIONS.................................................................................................................... 39

4.3.1 Loops .............................................................................................................................................. 40

4.3.1.1 Loops - View/Edit ..................................................................................................................................40

4.3.1.1.1 State.................................................................................................................................................42

4.3.1.1.2 Test Group........................................................................................................................................42

4.3.1.1.3 Zone .................................................................................................................................................42

4.3.1.1.4 Description (Device Text) .................................................................................................................42

4.3.1.1.5 Serial Number...................................................................................................................................42

4.3.1.1.6 Type..................................................................................................................................................42

4.3.1.1.7 Light..................................................................................................................................................43

4.3.1.1.8 Battery..............................................................................................................................................43

4.3.1.1.9 I/O Module Input Action....................................................................................................................44

4.3.1.1.10 Testing Luminaires..........................................................................................................................44

4.3.1.2 Loops - Auto Learn................................................................................................................................45

4.3.1.2.1 Normal Procedure / Initial learn........................................................................................................45

4.3.1.2.2 Procedure if the Panel finds Devices Missing...................................................................................45

4.3.1.2.3 Procedure if the Panel finds Devices Added.....................................................................................46

4.3.1.2.4 Procedure if the Panel finds Devices Changed ................................................................................46

4.3.1.3 Loops –Search PLU .............................................................................................................................46

4.3.1.3.1 Search All PLU .................................................................................................................................47

4.3.1.3.2 Assign From Panel Configuration Memory .......................................................................................47

4.3.1.4 Loops –Driver.......................................................................................................................................48

4.3.2 Zones .............................................................................................................................................. 48

4.3.3 Exit .................................................................................................................................................. 48

4.3.4 Tests ............................................................................................................................................... 49

4.3.4.1 Group ....................................................................................................................................................49

4.3.4.2 Date.......................................................................................................................................................49

4.3.4.3 Time ......................................................................................................................................................49

4.3.4.4 Period....................................................................................................................................................49

4.3.5 Time and Date................................................................................................................................. 50

4.3.6 View Options................................................................................................................................... 50

4.3.7 Passwords....................................................................................................................................... 50

4.3.8 PC Config........................................................................................................................................ 51

4.3.9 Setup............................................................................................................................................... 51

4.3.9.1 Network.................................................................................................................................................51

4.3.9.2 Panel Zone............................................................................................................................................51

4.3.9.3 Service Number.....................................................................................................................................51

4.3.9.4 Service Due Date ..................................................................................................................................51

4.3.9.5 Trace Logging Mode..............................................................................................................................52

4.3.9.6 Company LCD Logo..............................................................................................................................52

4.3.9.7 Program ID............................................................................................................................................52

www.acornfiresecurity.com

www.acornfiresecurity.com

5

4.3.9.8 Config Data............................................................................................................................................52

5SERVICE AND MAINTENANCE..................................................................................................................53

5.1 MAINTENANCE /INSPECTION SCHEDULE..................................................................................................53

5.1.1 Daily Actions ....................................................................................................................................53

5.1.2 Monthly Actions................................................................................................................................53

5.1.3 Quarterly Actions .............................................................................................................................53

5.1.4 Annual Actions.................................................................................................................................53

5.2 REPLACEMENT OF COMPONENTS ............................................................................................................54

5.2.1 Batteries...........................................................................................................................................54

5.2.1.1 Standby Batteries...................................................................................................................................54

5.2.1.2 Lithium Battery.......................................................................................................................................54

5.2.1.3 Printer Battery Pack...............................................................................................................................54

5.2.2 Liquid Crystal Display ......................................................................................................................55

6APPENDICES...............................................................................................................................................56

6.1 APPENDIX 1–FORGOTTEN LEVEL 3PASSWORD .....................................................................................56

6.2 APPENDIX 2–RECOMMENDED CABLES...................................................................................................57

6.3 APPENDIX 3–BATTERY STANDBY CALCULATION CHART.........................................................................58

6.4 APPENDIX 3–COMMISSION RECORD SHEET ...........................................................................................59

www.acornfiresecurity.com

www.acornfiresecurity.com

6

1 Introduction

1.1 Standards

The Lux Intelligent Addressable Emergency Lighting Control Panels conform to the requirements of the

following standards and codes of practice:

BS5266-1:2011 Code of practice for emergency lighting

EN50172:2004 / BS5266-8:2004 Emergency escape lighting systems

Low Voltage Directive 2006/95/EC

EN60950-1: 2006 +A12:2011 Safety of information technology equipment

Electromagnetic Compatibility Directive 2004/108/EC

EN61000-6-3:2007 +A1:2011 Emissions, Class B

EN50130-4: 1995 +A1:1998 +A2: 2003 Immunity, Product Family Standard

EN50130-4: 2011 Immunity, Product Family Standard

1.2 Cautions and Warnings

STOP

BEFORE INSTALLATION –Refer To the Ratings shown on the label inside the

product and to the ‘Specifications Chart’ in this document.

Please read this manual carefully. If you are unclear on any point DO NOT

proceed. Contact the manufacturer or supplier for clarification and guidance.

Only Trained service personnel should undertake the Installation, Programming

and Maintenance of this equipment.

This product has been designed to comply with the requirements of the Low

Voltage Safety and the EMC Directives. Failure to follow the installation

instructions may compromise its adherence to these standards.

ATTENTION

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE DEVICES

This equipment is constructed with static sensitive components. Observe anti-

static precautions at all times when handling printed circuit boards. Wear an

anti-static earth strap connected to panel enclosure earth point. Before

installing or removing any printed circuit boards remove all sources of power

(mains and battery).

1.3 Description

This manual covers the installation, programming, commissioning and use of the Lx-9400 Addressable

Emergency Lighting Control Panel. Additionally, a User Guide (Document No. 680-070) is also available.

The Lx-9400 is a Multiple Loop, Addressable Emergency Lighting Control Panel with provision for up to four

signalling loops and is designed for use with Emergency Light Luminaires equipped with the Advanced

Electronics Pulse addressing and monitor PLU module.

The Lx-9800 is a Multiple Loop, Addressable Emergency Lighting Control Panel with provision for up to eight

signalling loops and is designed for use with Emergency Light Luminaires equipped with the Advanced

Electronics Pulse addressing and monitor PLU module

Install the panel, signalling loops, monitored output circuits, etc. in accordance with the instructions in

Section 2 and then program the operation in accordance with the instructions detailed in Section 4.

User operation is described in Section 3.

www.acornfiresecurity.com

www.acornfiresecurity.com

7

1.3.1 System Features

The Lux Intelligent system provides real-time monitoring and automatic testing of emergency lighting. It is

designed to satisfy the requirements of BS5266 part 1 and prEN50172 standards for emergency lighting

systems.

Each Lux Intelligent control panel supports maintained, non-maintained and slave luminaires in either self-

contained central battery or static inverter systems.

The control panel electronics are housed in a high quality steel enclosure with sealed front label protecting the

control keys, LED Indicators and liquid crystal display. The graphic display is backlit to improve visibility in poor

ambient light conditions.

The system is modular in construction. For small systems, a single line driver is used to connect up to 249 Pulse

Line Unit (PLU) addressable luminaires or I/O modules over a 2-core cable. Each line driver takes the form of a

small, plug-in circuit card and each panel can control up to 4 line drivers. Further expansion is easily achieved

by networking up to 200 Lux Intelligent panels.

The installation may be divided up into a maximum of 200 Zones (1000 Zones when networked) to correspond

with the building fire zones, with each luminaire capable of being identified by its zone description and individual

location description. In addition, the installation may be divided up into 50 Test Groups, per panel, for automatic

or manual testing, thereby permitting the testing of alternate luminaires within a zone.

A User-friendly, menu driven software is used to assist in commissioning systems and for general operation of

the panel. Once luminaires are connected to the panel, a simple ‘Learn’ procedure is run to quickly identify the

quantity and types connected on each line.

Automatic testing can be carried out at any time of day or night. Flexible programming allows the time, date and

duration of test for multiple groups of lights to be quickly specified, with up to 400 unique time / date / periods

per year. The panels can be fully on site programmed using the front panel alphanumeric keypad. Alternatively,

the panel programming may be configured from a PC via the isolated RS232 serial port.

Alternatively, the data can be transferred to a database on a central PC for subsequent analysis, listing and

printing.

Remote monitoring is also possible via an internal modem option or using a serial to Ethernet converter.

Software running on a remote PC can be set to periodically dial into each panel and check for any faults. Again

proof of all tests carried out on each luminaire, showing the time, date and duration of each test can be

automatically printed from the PC.

An internal (or external) printer can be fitted to print the test results, etc. where the PC logging system is not

required.

1.3.2 Luminaire Control / Monitor Modules

The control panel is compatible with all Pulse Line Units. Models: Lxp-302, Lxp-304 Light Only, Lxp-110 I/O and

Lxp-111 AC Current to Light Converter.

The control panel is also compatible with the AEL-302 (luminaire powered) control / monitor module.

For full information on each module, refer to document 680-075. The salient features of each module are as

follows:

1.3.2.1 Lxp-302 Control / Monitor Module

The Pulse Line Unit is a device which checks for correct light levels, AC and battery power and provides the

following major features:

Self (Soft) Addressing –No DIL Switches to set in the luminaire fitting

Removal of double addressing at the panel –no need to go to luminaire

Loop powered so does not affect the luminaire battery supply

AC Mains sensing and control

Real-time Analogue Light Level Monitoring (via a unique fibre-optic sensor) available at the panel

Real-time Analogue Battery Level Monitoring available at the panel

www.acornfiresecurity.com

www.acornfiresecurity.com

8

1.3.2.2 Lxp-304 Light Monitor Module

The Pulse Light Only Line Unit is a device which checks for correct light levels, but does not monitor a battery or

AC supply and provides the following major features:

Self (Soft) Addressing –No DIL Switches to set in the luminaire fitting

Removal of double addressing at the panel –no need to go to luminaire

Loop powered so does not affect the luminaire battery supply

Real-time Analogue Light Level Monitoring (via a unique fibre-optic sensor) available at the panel

1.3.2.3 Lxp-110 I/O Control Module

The Pulse Input/Output Line Unit is available to support central battery systems, or any other situation in which

additional loop powered inputs or outputs are required and provides the following major features:

Self (Soft) Addressing –No DIL Switches to set in the luminaire fitting

Removal of double addressing at the panel –no need to go to luminaire

Loop powered

Output Relay to control the central battery / static inverter luminaire test operation

Input for monitoring of Alarms or Warnings

1.3.2.4 Lxp-111 AC Current to Light Converter

The Pulse Line Unit provides the following major features:

AC powered so does not affect the luminaire battery supply

Senses current drawn by the lamp and converts to a light output for monitoring via the Lxp-302 or Lxp-

304 modules.

Suitable for applications where it is not possible / convenient to monitor the actual light –e.g. tungsten

lamps.

www.acornfiresecurity.com

www.acornfiresecurity.com

9

1.4 Installation Approvals

1.4.1 Emergency Lighting Installations

The panel must be installed and configured for operation in accordance with these instructions and the

applicable code of practice or national standard regulations for emergency lighting systems installation

appropriate to the country and location of the installation.

1.4.2 Wiring Regulations

The panel and system must be installed in accordance with these instructions and the applicable wiring codes

and regulations appropriate to the country and location of the installation.

Insulation coordination for equipment within low voltage systems:

The normal category for fire detection and fire alarm products (and associated equipment) is as permanently

connected equipment supplied from the building wiring (Overvoltage Category II). The equipment is not

classified as being an integral part of the building wiring (Overvoltage Category III).

In accordance with EN60950-1, the products are assessed to, and comply with, the requirements for

Overvoltage Category II devices for connection to the AC Mains supply.

This category is the normal category for this type of equipment and installation and the use of additional surge

protection devices (SPD) is not normally required.

However:

- If the equipment is subjected to special requirements with regard to reliability and availability, or

- If the equipment is likely, when installed, to be subjected to transient over-voltages that exceed Category II,

then

Additional surge protection devices (SPD) shall be provided in the AC Mains Supply feed to the equipment to

limit any overvoltage transients to the levels of Category II.

www.acornfiresecurity.com

www.acornfiresecurity.com

10

2 Installation

2.1 Identification of Parts

The diagram opposite shows

the major parts of the panel.

2.2 Installing the Lx-9400 Enclosure

The panel can weigh in excess of 20kg when the batteries are installed. Use

the appropriate fixing hardware necessary to secure the panel to the wall.

Observe recommended lifting practices to guard against spinal injury.

2.2.1 Opening the Enclosure Cover

The Lx-9400 is provided with a captive screw fixing for securing the hinged door to the back box.

The Lx-9400/D and Lx-9800 are provided with key-lock assemblies for securing the hinged door to the back

box. Insert and turn the key to open the enclosure.

2.2.2 Removing the Chassis

It is recommended that the chassis be removed

before fitting the panel to the wall. To remove

the chassis:

Refer to the diagram opposite.

Disconnect the earth cable connecting the

chassis to the spade terminal on the rear

enclosure.

Remove the bottom two screws holding the

chassis to the back box. Keep these items in a

safe place for later re-use.

Loosen the top two screws holding the chassis

to the back box via the keyhole slots. The

chassis assembly can now be removed.

Carefully remove the chassis from the rear

enclosure and place in a safe place to prevent

accidental damage.

Do not lift the chassis by holding onto any of the printed circuit cards. Hold

the chassis by the metal plate only.

www.acornfiresecurity.com

www.acornfiresecurity.com

11

2.2.3 Mounting the Enclosure

Firstly, remove the required knockouts for the

installation wiring. There are sufficient knockouts

on the top of the enclosure for all installation

wiring. In addition, there are knockouts at the top

of the back wall, if required, for rear entry cabling.

The diagram opposite shows the positions of the

four holes. Use all four positions to ensure the

panel is held securely to the wall.

Drill the required holes in the supporting wall

using a drill bit diameter 7.0 mm and plug with a

suitable 40mm long expansion plug. Affix the

panel to the wall with M5 screws (length 40mm)

or No.10 screws (length 1½”).

Ensure that there is sufficient space to allow the

door to be opened when the panel is mounted.

Finally, use a brush to remove any dust or swarf

from inside the enclosure.

Enclosure Size and Fixing Point Dimensions

9400

450

380

35

25

385

340

Earth

Studs

x4

Cable Tie Anchor

Points x9

9400/D

450

380

35

25

475

405

Earth

Studs

x4

Cable Tie Anchor

Points x9

9800

450

380

35

20

515

370

950

2.2.4 Remounting the Chassis

Carefully replace the chassis and locate onto the upper two screws. Replace the bottom two screws and tighten

all four screws to hold the chassis securely to the back box.

Reconnect the chassis earth cable to the spade terminal in the rear of the enclosure.

www.acornfiresecurity.com

www.acornfiresecurity.com

12

2.2.5 Recommended Cable Routing Arrangement

Internal arrangement showing recommended routing of cables.

It is recommended that the

routing arrangement shown

in the diagrams opposite

be employed.

Segregate the SELV low

voltage wiring (Loop

Circuit, Network and AUX

Supply) from the AC Mains

Wiring and any wiring

connected to the relay

contacts and modem

telephone connection lead.

Eyelets are provided in the

rear of the back box to

enable the cables to be

securely fastened using tie-

wraps.

Cable screens / shields

should be connected to the

back box using the

threaded studs provided

near the knockout holes.

Multi-way Bus bars are

available separately for

mounting on the threaded

studs.

Refer to Appendix 2 –

Recommended Cables for

further information on cable

types to be used.

Refer to specific sections

on how to install AC Mains

input and loop, phone,

relay and AUX outputs

circuits.

9400, 9400/D

9800

Use front

knockout rows

for upper

chassis cables

Use rear

knockout rows

for lower chassis

cables

Route battery

cables through

hole in upper

battery shelf –

Ensure that the

hole is protected

by a grommet.

Field

Installation

Wiring

Battery Wiring

www.acornfiresecurity.com

www.acornfiresecurity.com

13

2.2.6 Installing Additional Option Modules

Isolate ALL sources of power before installing or removing printed circuit boards.

ATTENTION

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE DEVICES

Observe anti-static precautions at all times when handling printed circuit

boards.

2.2.6.1 Additional Signalling Line Circuits

To extend the number of signalling line circuits /

loops or to replace an existing loop driver card

(Lxp-901) follow the procedure described below.

An example of the loop driver is shown opposite.

This is provided with a plastic grip handle on the

top edge to ease removal of the card from the

Base Card.

Open the enclosure and then open the display

plate (it is hinged on the right hand side and there

is a magnetic catch strip on the left-hand side) to

gain access to the Base Card.

A section of the Base Card identifying the

locations for each loop driver is shown in the

picture opposite.

Loop Driver –Component Side View

To install a loop driver, remove the retaining strap,

then gently guide the loop driver printed circuit

card into the guide slots of the machined end

blocks and then push into place onto the

connector on the Base Card.

Ensure that the pins of the connectors are

correctly aligned. The loop driver should be

inserted with the component side of the board

placed on the left-hand side. Replace the retaining

strap.

The Base Card can accept up to four signalling

line driver cards –it does not matter which

positions are used. Ensure that the signalling line

wiring is made to the terminal block positions

appropriate to the line driver cards actually

installed.

Close the chassis display plate and then close up

the enclosure.

Component side of

Loop Driver Card

Machined End

Block

LOOPS

1

2

3

4

2.2.6.2 Removing a Loop Driver Card

To remove a loop driver, remove all power and follow the procedure above but:

Take a firm hold of the lever located on top of the loop driver card. Gradually and carefully pull the loop

driver vertically away from the base card and guide it out of the slots in the machined end blocks.

Replace with the replacement card as described above.

www.acornfiresecurity.com

www.acornfiresecurity.com

14

2.2.6.3 Integral Modem Option

The modem card option may be supplied factory

installed when the control panel is ordered. It is

mounted on the chassis plate, on pre-installed

pillars, to the left of the base card. 4x M3 Screws

are used to secure the card to the chassis.

The card requires power from the AUX 24V DC

output on the base card. Take care to ensure that

the wires are connected AUX 0V to 0V input and

AUX V+ to +24V input.

The RS232 connections should be connected:

Modem Card Base Card

GND > EXT GND

TX > RX

RX > TX

The phone cable should be routed through a

gland using one of the 20mm knockouts. Route

the cable away from LV Mains and SELV wiring.

2.2.6.4 Integral Network Option Cards

The network card may be supplied factory

installed when the control panel is ordered.

The card is mounted on the chassis plate, on pre-

installed pillars, to the right of the base card.

There are three snap-in pillars. The card is

secured to the chassis with an M3 screw in the

fourth position –it is vital that this mounting point

is used and made secure to provide an earth point

connection for the cable screen connections.

The network card is connected to the base card

using a ribbon cable.

Refer to the documentation supplied with the

network card for detailed information on

networking. (Ad-Net Document No. 680-027).

2.2.6.5 Integral Printer Option

This unit is normally supplied fitted when the panel is ordered.

It is mounted on the chassis door to the left of the display card. Refer to the documentation supplied

with the printer kit for fitting / replacement instructions.

2.2.6.5.1 Printer Power Supply

The printer has an integral rechargeable battery that is dedicated to the printer power supply. If the main panel

power supply has been turned off for a long period (i.e. more than a month), the battery will need to recharge

before printing. Under these conditions, allow 1 hour before performing a test print and 24 hours before normal

printing.

www.acornfiresecurity.com

www.acornfiresecurity.com

15

2.2.6.5.2 Printer Diagnostics

LED state

Description

Steady Flash (once per second)

Normal operation

Off

No power. Check that the ribbon cable connecting the

printer to the display has been fitted.

Rapid Flash

(Four times per sec)

Printer not ready. Check: -

Paper roll inserted

Paper holder door fully closed

Battery pack not connected

Battery flat (see notes on power supply)

2.2.6.5.3 Changing the Paper Roll

The printer mechanism is a simple clamshell

design.

Open the printer cover and remove the existing

paper roll.

Pull off a length of paper and insert the roll as

shown opposite.

Close the cover ensuring that it is snapped shut.

Perform a Test Print to ensure that the printer is

fully working.

www.acornfiresecurity.com

www.acornfiresecurity.com

16

2.3 Wiring Installation

All electrical wiring installation work should be carried out in accordance with the code of practice or applicable

national standards appropriate to the country of installation.

To maintain electrical integrity of the SELV wiring on the input, output, loop and communications lines all SELV

wiring should be segregated from the LV mains wiring and be wired using cable with insulation suitable for the

application.

To minimise the effects of EMC interference all data wiring circuits should be wired with a twisted pair of

conductors with a cross sectional area suitable for the loading conditions.

In areas where cabling may come into contact with high frequency interference, such as portable radio

transceivers etc. the data wiring cable should be of a twisted pair construction within an overall screen. Care

should be taken to correctly terminate this screen, refer to the appropriate sections of this manual for further

information for each circuit type.

NB: Minimum / Maximum cable size for all external connections is limited to 0.5mm² / 2.5mm² (22-14AWG).

2.3.1 AC Mains Wiring

Route the high voltage mains AC wiring into

the enclosure at the upper left corner only.

Keep the AC wiring away from the circuit

boards and all other wiring.

Connect the Control Panel to the mains supply

via a readily accessible disconnect-device

(Isolation Switch) and suitable earth fault

protection incorporated in the building

installation wiring. The Mains cable should be

0.75mm2cable rated at 250V and fused via a

5A anti-surge fuse.

FUSE

Brown

Green

LIVE

EARTH

NEUTRAL

Panel Wiring

Blue

3.15A

AC Mains terminations

The Lx-9800 employs two terminal blocks for

the AC Mains connections (one on each

chassis assembly) as per the Lx-9400.

Must be

earthed

The panel must be connected

to the supply earth through the

power cable.

The mains input connector is shown in the

diagram opposite. Note the positions of the

earth, neutral and live terminal connections.

These are clearly marked on the label next to

the connector. The connector block contains

an integral fuse holder.

Secure the mains input wiring by tie wrap as

close to the terminal block as possible.

The fuses are rated as follows:

T 3.15A H 250V

Replace with correct rating and specification

only.

2.3.1.1 Cable Gland

The cable gland and any cord clamp bushing s used in routing the Mains

cable through the 20mm knockout must have a minimum flame-retardant

rating of 94HB.

Suggested glands and bushings are: -

Type

Gland IP65 –Brass M20, EExd / Eexe

Gland IP68 –Nylon 66 M20 Black, UL94V2

Bushing –Nylon 66 M20 Black, UL94V2

Manufacturer

Lappcable

Multicomp

Multipcomp

www.acornfiresecurity.com

www.acornfiresecurity.com

17

2.3.2 Battery Installation

The panel requires two 12V batteries for standby

operation.

The battery leads are connected onto the base

card via a two-part plug and socket, as shown in

the diagram opposite.

Refer to the Specifications for minimum and

maximum battery sizes allowed.

Refer to Appendix 3 –Battery Standby

Calculation Chart to determine the battery size

needed for the required standby duration period.

BAT +

BAT –

AUX -

AUX +

Place the batteries in the bottom of the enclosure

and connect the ‘Red’ lead to the positive (+)

terminal of battery #1 and the ‘Black’ lead to the

negative (-) terminal of battery #2. Connect the

negative of battery #1 to the positive of battery #2

using the supplied link cable.

Ensure that the battery terminals do not short out

against any part of the enclosure, circuit board or

chassis plate.

+

-

+

-

+

-

#1

#2

RED

BLACK

Link Cable

Do not make the final battery connections until the installation wiring is completed and

the system is to be powered up.

Always connect the AC Mains input before connecting the battery.

New batteries require ‘top-charging’ before installation. Refer to Section 5.2.1.1 for a list

of recommended batteries.

The diagrams opposite

show the recommended

location and orientation

of the batteries within

the panel.

For battery sizes greater

than 12AH, it will be

necessary to remove the

spade terminals fixed to

the battery leads and

replace these with

connection fixings

suitable for the installed

batteries.

Replacement Fuse

FS1 T6.3A 250V Anti-

Surge

9400

7AH/

12AH

7AH/

12AH

9400/D

17/38Ah

17/38Ah

9800

Battery Shelf

Loops 1-4

Battery Shelf

Loops 5-8

17Ah to

38Ah

17Ah to

38Ah

17Ah to

38Ah

17Ah to

38Ah

www.acornfiresecurity.com

www.acornfiresecurity.com

18

2.3.3 Signalling Line Installation

2.3.3.1 General Considerations

The Line Driver Module, shown opposite, provides power

and signalling pulses for the digital communications with the

luminaires.

Up to four Line Drivers can be installed in the panel. Refer

to Section 2.2.6 for details of how to install additional line

drivers.

Route the signalling circuit away from other electrical cables

to minimise the effect of electrical interference. It is

recommended that a 2-Core Twisted-Pair cable be used. In

extremely noisy conditions, the use of a cable with external

screen is recommended.

Refer to Appendix 2 –Recommended Cables for further

information on cable types to be used.

When screened cable is used, it is vital to connect the screen / drain wire to the chassis

/ earth at the cable gland input / earth stud in the panel. Always ensure that all segments

of the cable loop have continuity of the screen and take care to ensure that the screen is

not exposed to any other earth point (e.g. metalwork, cable trays, junction boxes, etc.).

The outputs of the Line Driver Module are short circuit

protected. The wiring can be connected in Radial Format or

as a Loop Circuit (Preferred Method).

For ease of maintenance and connection, the wiring is

terminated in a plug and socket arrangement, shown

opposite.

The signalling circuit consists of a pair of wires (+ and –).

Four terminals are provided to enable loop operation.

IN –

IN +

OUT –

OUT +

Base Card Terminations (Typical).

2.3.3.2 Radial Wiring Format

To wire the signalling circuit as a Radial Line, connect one wire of the 2-

Core cable to one of the (+) terminals and connect the other wire to one of

the (–) terminals.

Route the cable to each of the luminaires in turn.

Connect Jumper Wires between OUT+ / IN+ and OUT–/ IN–.

Total Cable length (from Line Driver to last Luminaire in wiring run) should

not exceed 1500 metres.

The cable length depends on the line loading, cable core diameter –Refer

to Appendix 2 –Recommended Cables for a list of recommended cables

and distances.

+

-

Line Out

IN –

IN +

OUT –

OUT +

Connect the wiring to the terminal blocks in the

Luminaire.

The connections on the

Pulse

Line Unit

are not

polarity specific. However, it is recommended that

terminals (B) are used for the (+) signal line and

terminals (A) are used for the (–) signal line.

-

+

From

Panel

To next

Luminaire

Luminaires

To maintain signal line supervision, break the wiring run at each Luminaire. The

Luminaire is provided with two B and two A terminals.

www.acornfiresecurity.com

www.acornfiresecurity.com

19

If a screened cable is used in a radial circuit, the screen at the end of the cable run

should also be connected to earth. If there is a voltage potential difference between the

panel earth and the remote earth point, connect the screen to the earth point via a 2.2F

polyester (non-polarised) capacitor of suitable voltage rating.

2.3.3.3 Loop Wiring Format

PREFERRED METHOD –A fault condition will be indicated if an open

circuit condition wiring occurs but the panel will still communicate with all

luminaires.

To wire the signalling circuit as a Loop circuit, connect one wire of the 2-

Core cable to one of the (+) terminals and connect the other wire to one of

the (–) terminals.

Route the cable to each of the luminaires in turn.

Return the wiring to the Line Driver and connect the two wires to the

remaining (+) and (–) terminals. See diagram opposite.

Connect the wiring to the terminal blocks in the Luminaire.

Total loop length (from Line Driver OUT to Line Driver IN) should not

exceed 1500 metres.

The cable length depends on the line loading, cable core diameter –Refer

to Appendix 2 –Recommended Cables for a list of recommended cables

and distances.

+

-

+

-

Line

OUT

Line

RETURN

IN –

IN –

OUT +

OUT +

The connections on the

Pulse

Line Unit

are not polarity

specific. However, it is

recommended that terminals

(B) are used for the (+) signal

line and terminals (A) are

used for the (-) signal line.

-

+

From

Panel

Luminaires

-

+

Return to

Panel

A

B

C

D

To maintain signal line supervision, break the wiring run at each Luminaire. The

Luminaire is provided with two B and two A terminals.

2.3.3.4 Pulse Luminaire Serial Numbers

Each

Pulse

Line Unit

has a unique serial number. This serial number is printed on a self-adhesive label attached

to the module or luminaire enclosure.

As each luminaire is installed and wired to the system, tear off the spare serial number label and affix to the

installation record chart supplied with the panel. This will enable quick and simple allocation of soft addresses to

each PLU and will provide a record of the installation for future reference.

2.3.4 Auxiliary Supply Output

The Lx-9400 is equipped with an auxiliary 24V DC, 300mA

power supply output.

This can be used for powering ancillary equipment.

Each chassis of the Lx-9800 has its own AUX output.

BAT +

BAT –

AUX –(GND)

AUX + (24V)

Lx-9400

www.acornfiresecurity.com

www.acornfiresecurity.com

20

3 User Operation

3.1 Controls and Indications

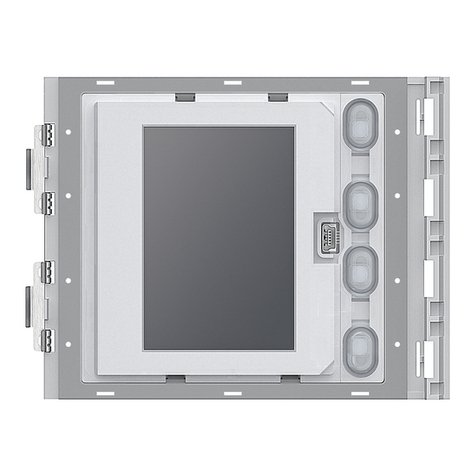

The Lx-9400 is provided with indications and control functions as shown in the diagram below and described in

the following text. Normal operator level indications, controls and user programming can all be achieved using

either display.

3.1.1 Graphical Display

The graphical display provides detailed information of the source of faults and warnings. It also shows menus

for use when inspecting or programming the operation of the panel.

Under normal conditions the panel display shows the access level, time, date and status: -

16:05

04 MAR 2002

LIGHT MONITORING SYSTEM

(Press Menu to View)

!!

UDF2

UDF1

RESET

MUTE

ESC MENU

PQRS WXYZTUV

GHI JKL MNO

DEFABC

TEST

POWER

Ratings: 220V-240V

1A (Max) 47Hz-63Hz

EMERGENCY LIGHTING

TESTING SYSTEM

Graphical

Display

Navigation

Buttons

Status

Indications

Control

Buttons

Numeric

Keypad

www.acornfiresecurity.com

www.acornfiresecurity.com

This manual suits for next models

3

Table of contents

Other Advanced Control Panel manuals

Advanced

Advanced MxPro4 Series User manual

Advanced

Advanced Ex-3001 User manual

Advanced

Advanced ExGo Series User manual

Advanced

Advanced Quick Zone XL Guide

Advanced

Advanced LIFELINE Px-100 User manual

Advanced

Advanced MxPro4 Series User manual

Advanced

Advanced MxPro 5 Installation and operating instructions

Advanced

Advanced Mx Pro 4 User manual

Advanced

Advanced MxPro 4 4100S User manual

Advanced

Advanced LIFELINE Px-100 User manual