Table of Contents Page

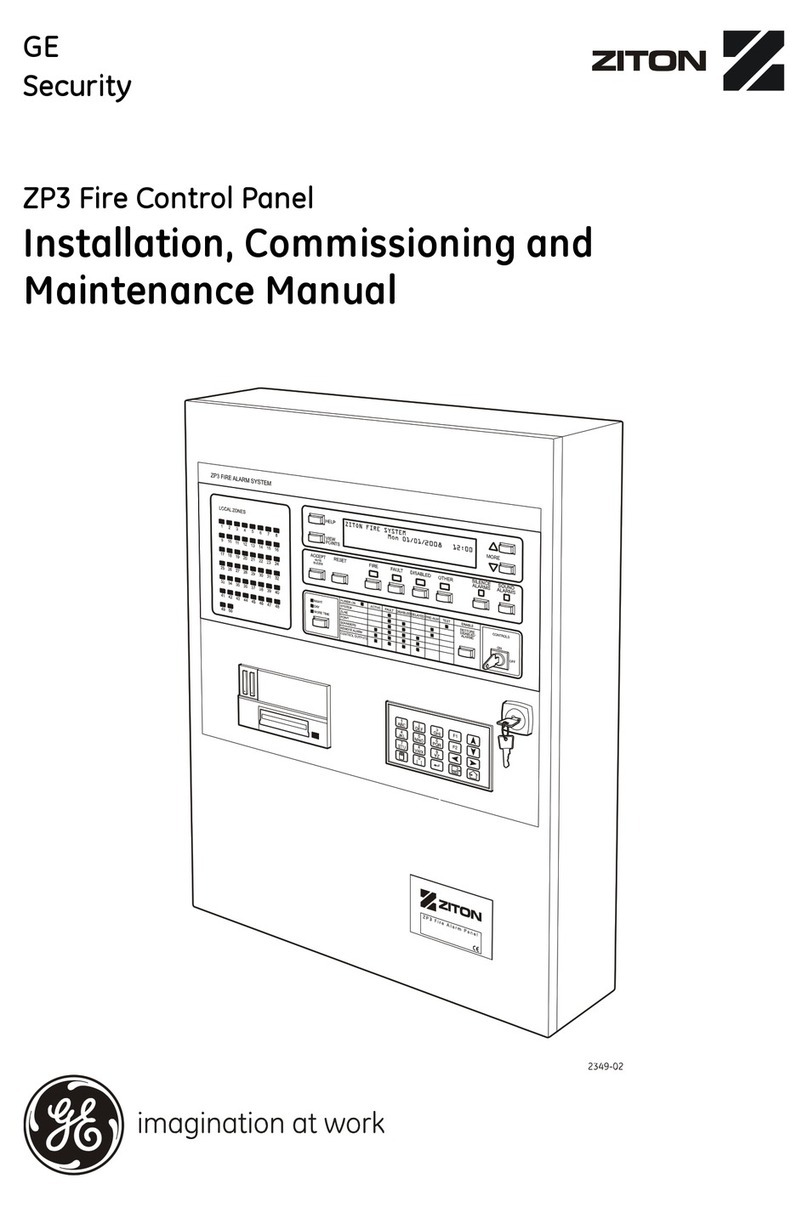

1ABOUT THIS PANEL.....................................................................................................................................4

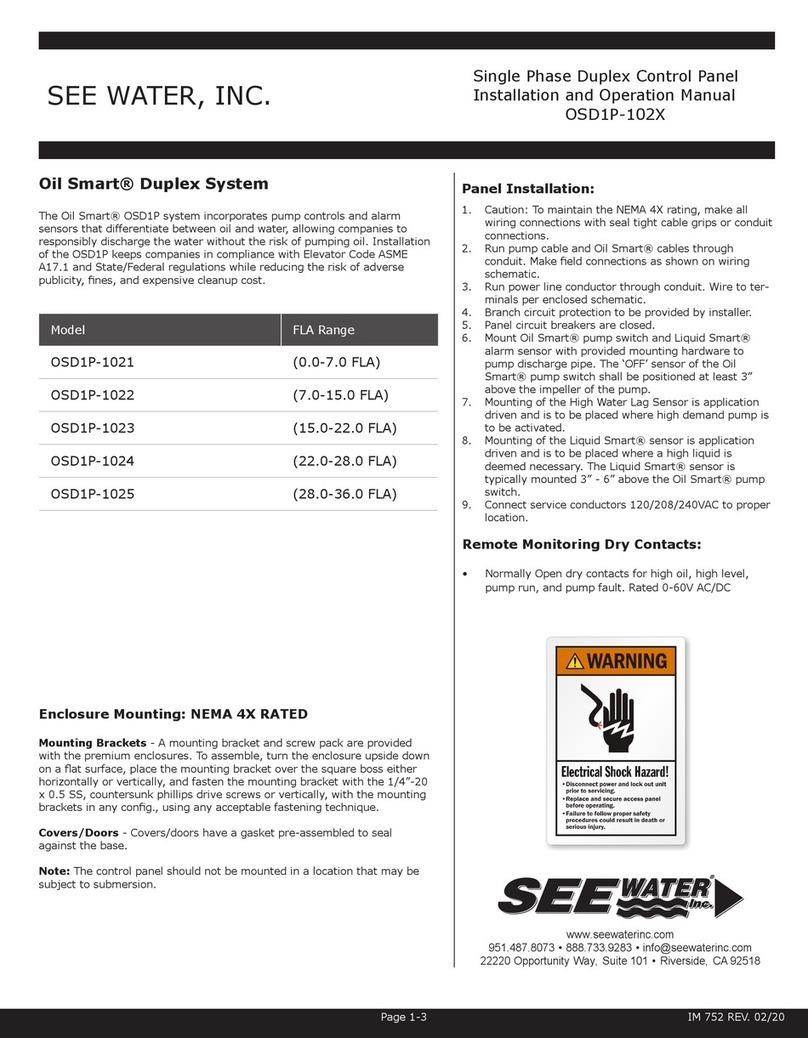

1.1 PRODUCT OVERVIEW .........................................................................................................................4

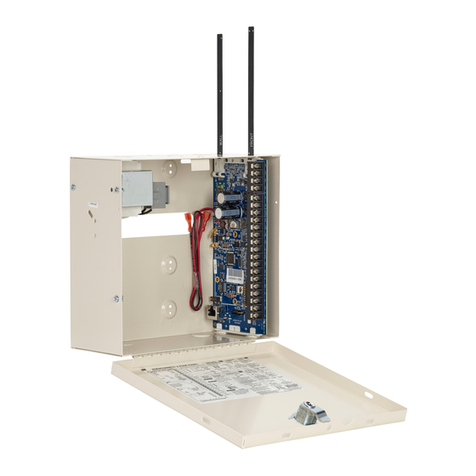

1.2 CABINET DETAILS ...............................................................................................................................5

1.3 CIRCUIT BOARDS ................................................................................................................................6

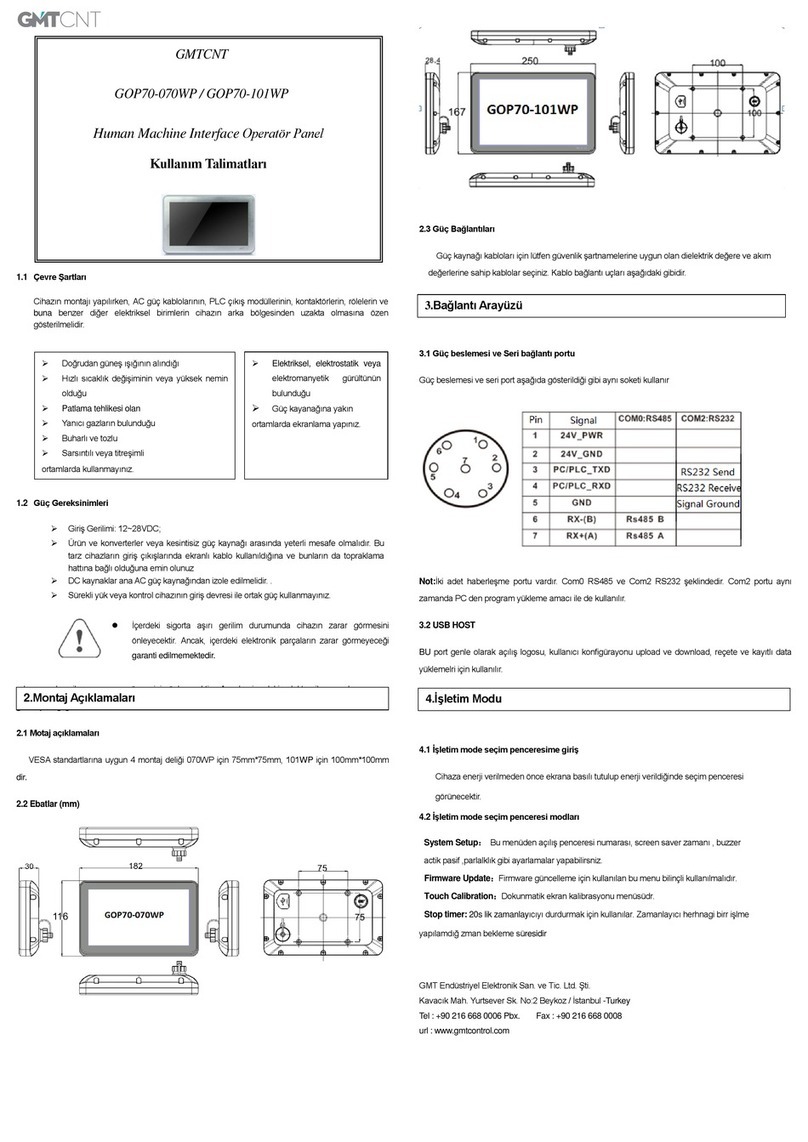

1.4 MAIN PCB TERMINALS........................................................................................................................8

1.5 ZONE CARD TERMINALS ....................................................................................................................9

1.6 TECHNICAL SPECIFICATION............................................................................................................10

1.7 POWER SUPPLY MODULE................................................................................................................11

2DESIGN CONSIDERATIONS.......................................................................................................................12

2.1 SYSTEM DESIGN &PLANNING.........................................................................................................12

2.1.1 CABLE TYPES & LIMITATIONS .....................................................................................................13

2.1.2 CABLING .........................................................................................................................................13

2.1.3 CABLE LENGTHS...........................................................................................................................13

2.1.4 MAINS PROVISION.........................................................................................................................13

2.2 GENERAL CONVENTIONAL SYSTEM SCHEMATIC........................................................................14

2.3 GENERAL TWIN WIRE SYSTEM SCHEMATIC..................................................................................15

3INSTALLATION............................................................................................................................................16

3.1 SAFETY ...............................................................................................................................................16

3.2 ESD PRECAUTION .............................................................................................................................17

3.3 GENERAL............................................................................................................................................17

3.4 MOUNTING THE CABINET.................................................................................................................17

3.5 MAINS CONNECTIONS ......................................................................................................................18

3.6 CONNECTING THE BATTERIES........................................................................................................19

3.7 BATTERY CHARGING VOLTAGE CHECKS......................................................................................19

4SETUP & PROGRAMMING .........................................................................................................................20

4.1 TWIN WIRE MODE ..............................................................................................................................20

4.2 ZONE INTERFACE FUNCTION ..........................................................................................................21

4.3 LEVEL 3ENGINEERING OPTIONS....................................................................................................22

4.4 OPTIONS INDEX .................................................................................................................................23

5OPERATING.................................................................................................................................................48

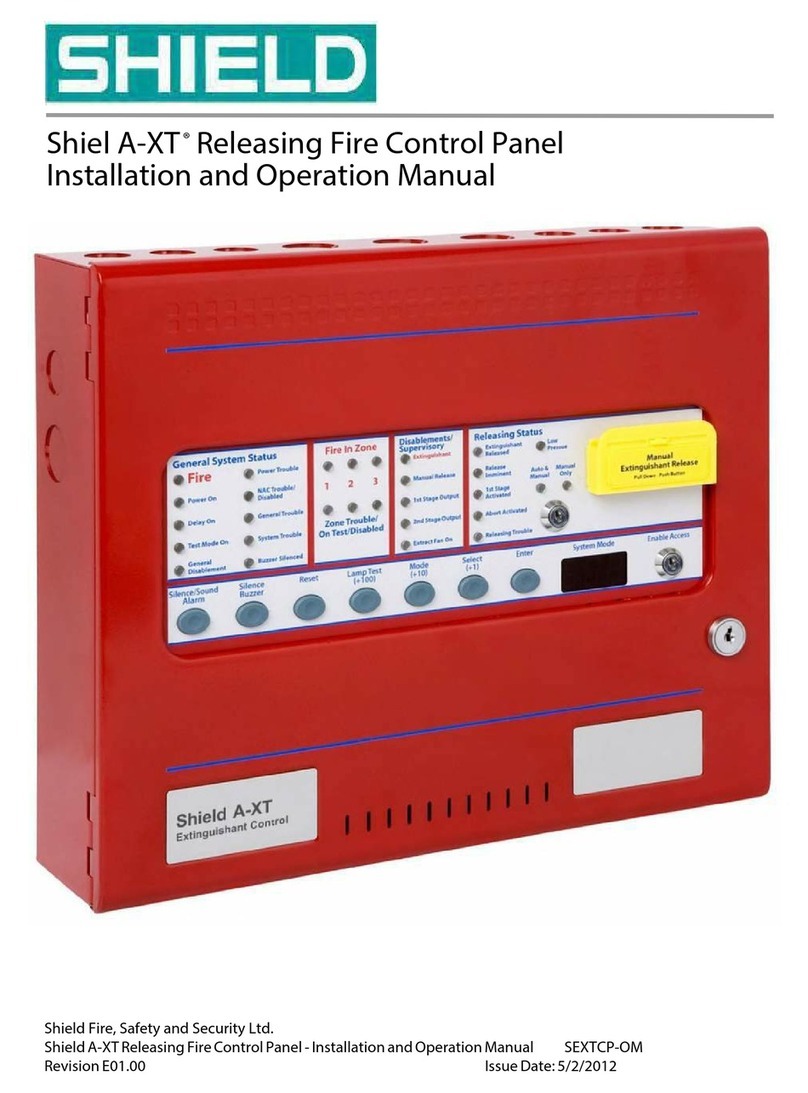

5.1 PANEL CONTROLS &INDICATIONS ................................................................................................48

5.1.1 Status LED Indicators ......................................................................................................................49

5.1.2 Keypad.............................................................................................................................................49

5.2 DISABLE MODE..................................................................................................................................50

5.3 TEST MODE.........................................................................................................................................51

5.4 FAULT DIAGNOSIS.............................................................................................................................52

5.5 FUNCTIONALITY DURING ASYSTEM FAULT .................................................................................53

5.6 USER INSTRUCTIONS........................................................................................................................53

6SERVICE & MAINTENANCE.......................................................................................................................54

6.1 THE NEED FOR MAINTENANCE .......................................................................................................54

6.2 DUTIES OF THE RESPONSIBLE PERSON........................................................................................54

6.3 ROUTINE MAINTENANCE &TESTING..............................................................................................54

6.3.1 DAILY...............................................................................................................................................54

6.3.2 WEEKLY..........................................................................................................................................54

6.4 PERIODIC INSPECTION &SERVICING.............................................................................................56

6.4.1 SCHEDULE OF TESTING LOG BOOK...........................................................................................57

6.4.2 FALSE ALARMS, FAULTS & ENGINEER VISIT LOG BOOK ........................................................61

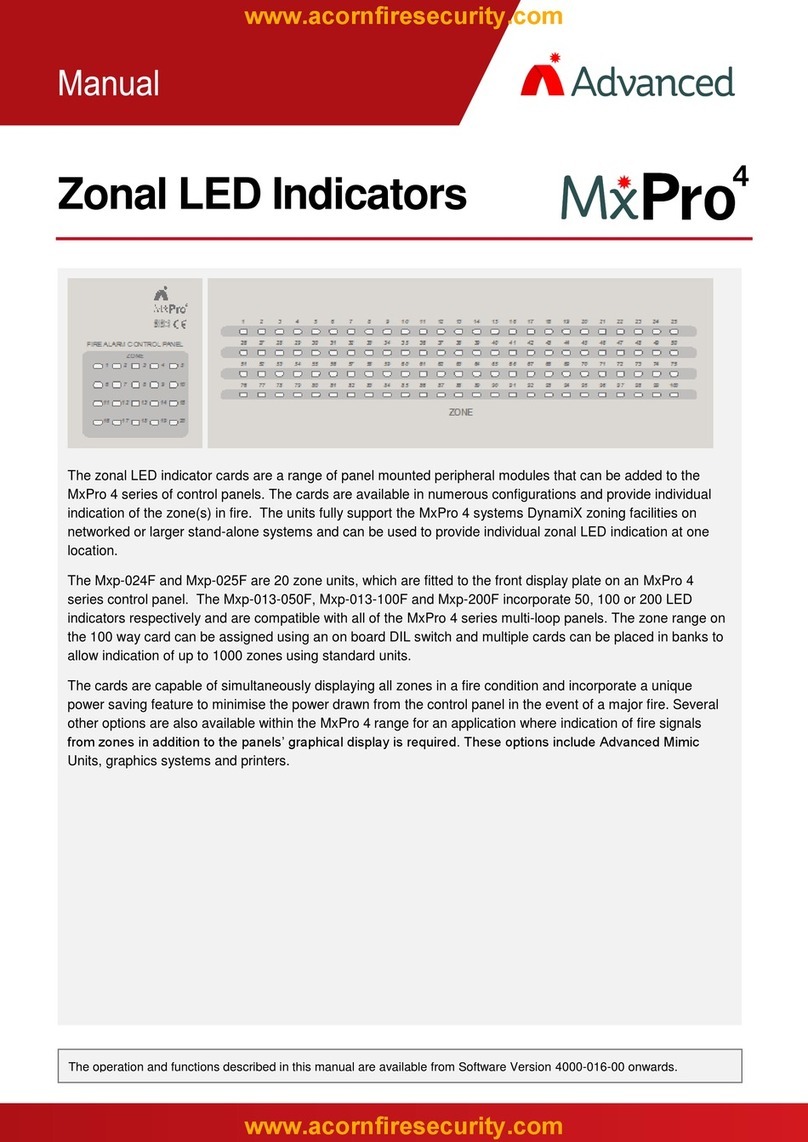

www.acornfiresecurity.com

www.acornfiresecurity.com