UG 20-UG 25-OI-vers. 3.5 gb. 20190409 3

Table of contents

Table of contents ........................................................................................................ 3

1.0.0 EC Declaration for Incorporation (Document original) ....................................... 5

1.1.0 According to: 2006/42/EG .............................................................................. 5

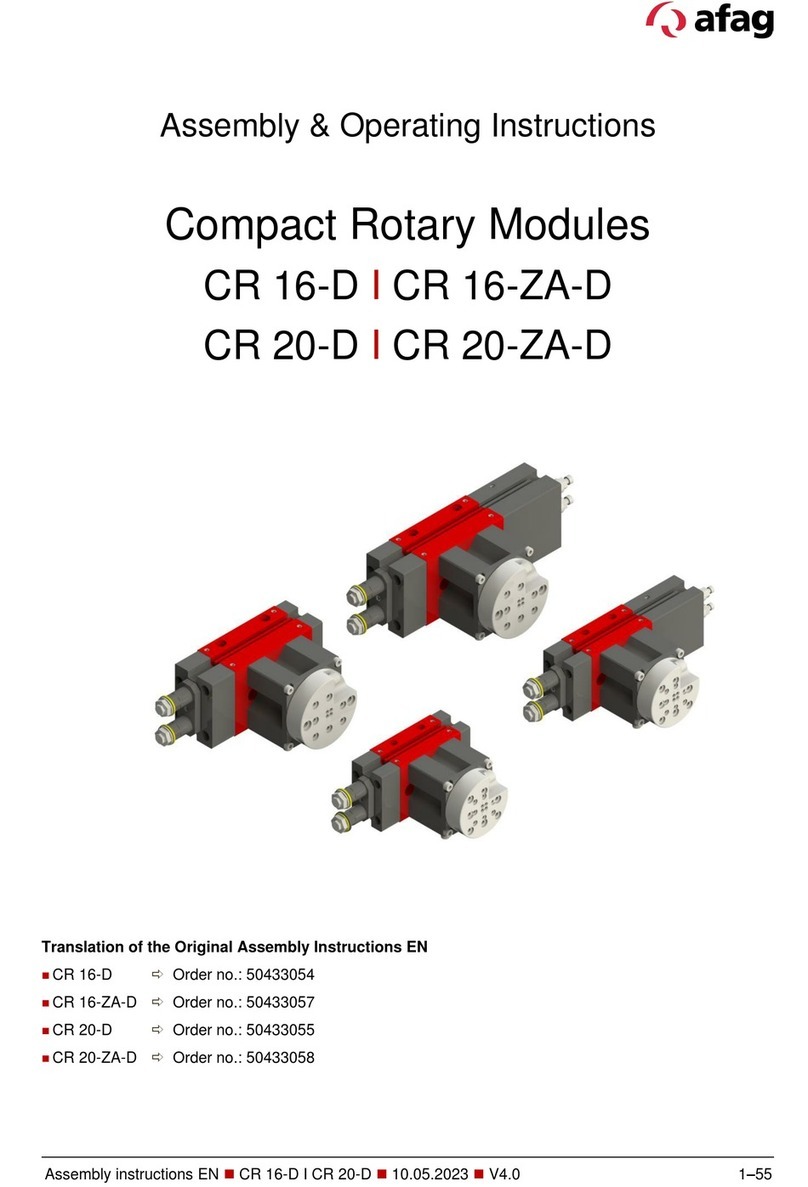

2.0.0 Module Information ............................................................................................ 6

2.1.0 Transport and storage (packing and unpacking) ............................................ 6

2.1.1 Assembly for the gripper ................................................................................ 7

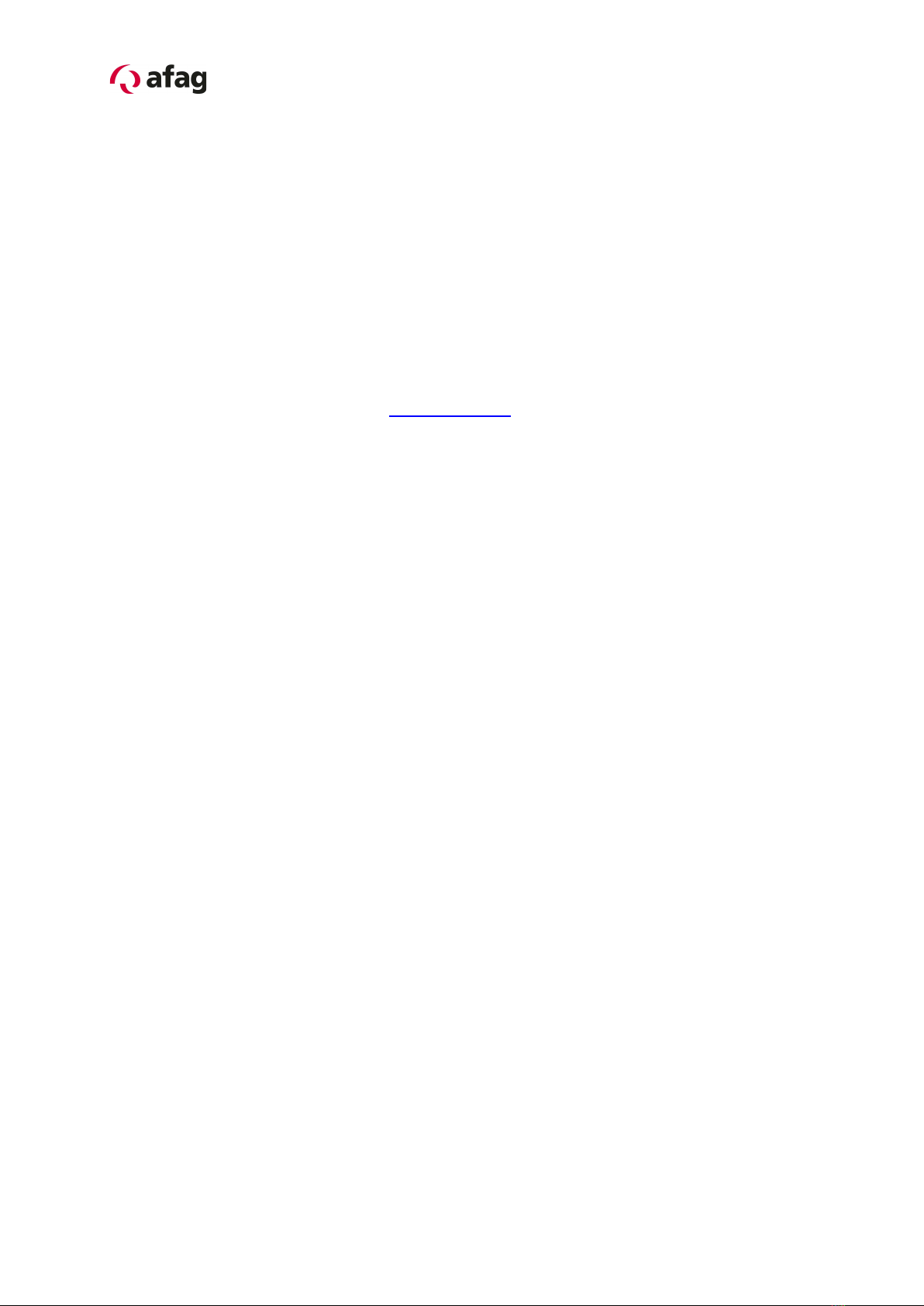

2.1.2 Mounting for the gripper finger ....................................................................... 7

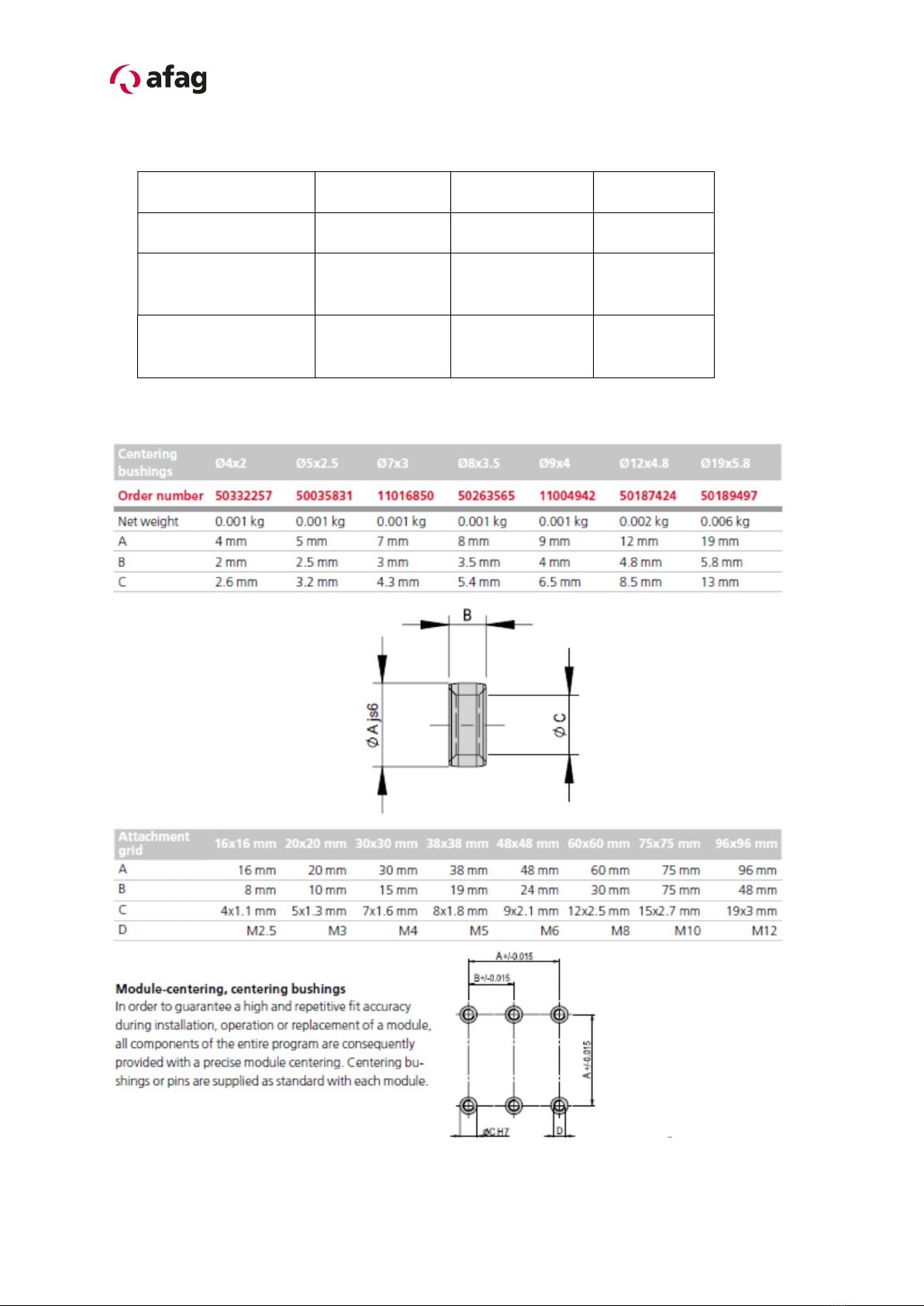

2.1.3 Hole matrix and centering bushings ............................................................... 8

2.1.4 Tightening torques for bolts ............................................................................ 9

3.0.0 Montage Instructions (Document original) ....................................................... 10

3.1.0 Manufacturer address: ................................................................................. 10

3.1.1 Symbols ....................................................................................................... 11

3.1.2 General description ...................................................................................... 11

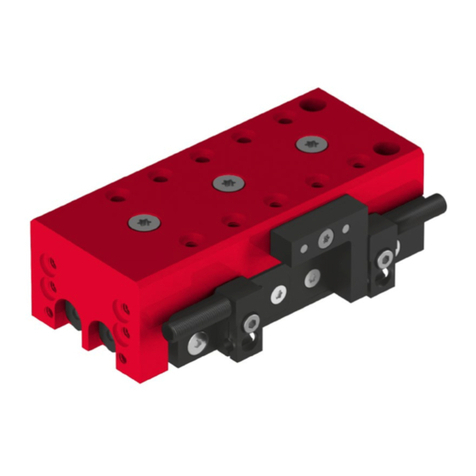

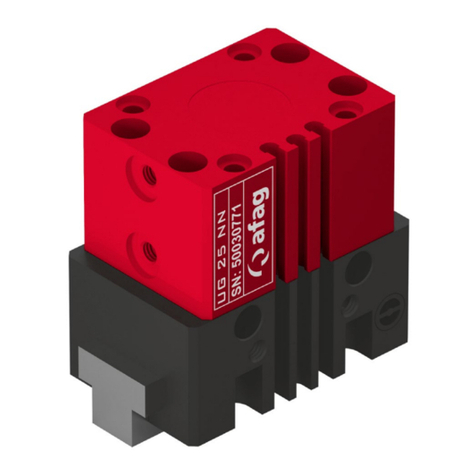

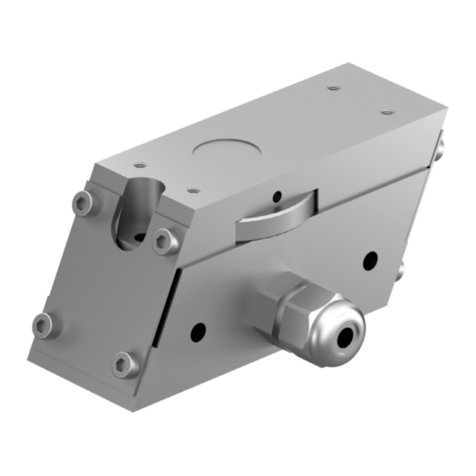

3.1.3 General description for the module UG 20 / UG 25 ..................................... 12

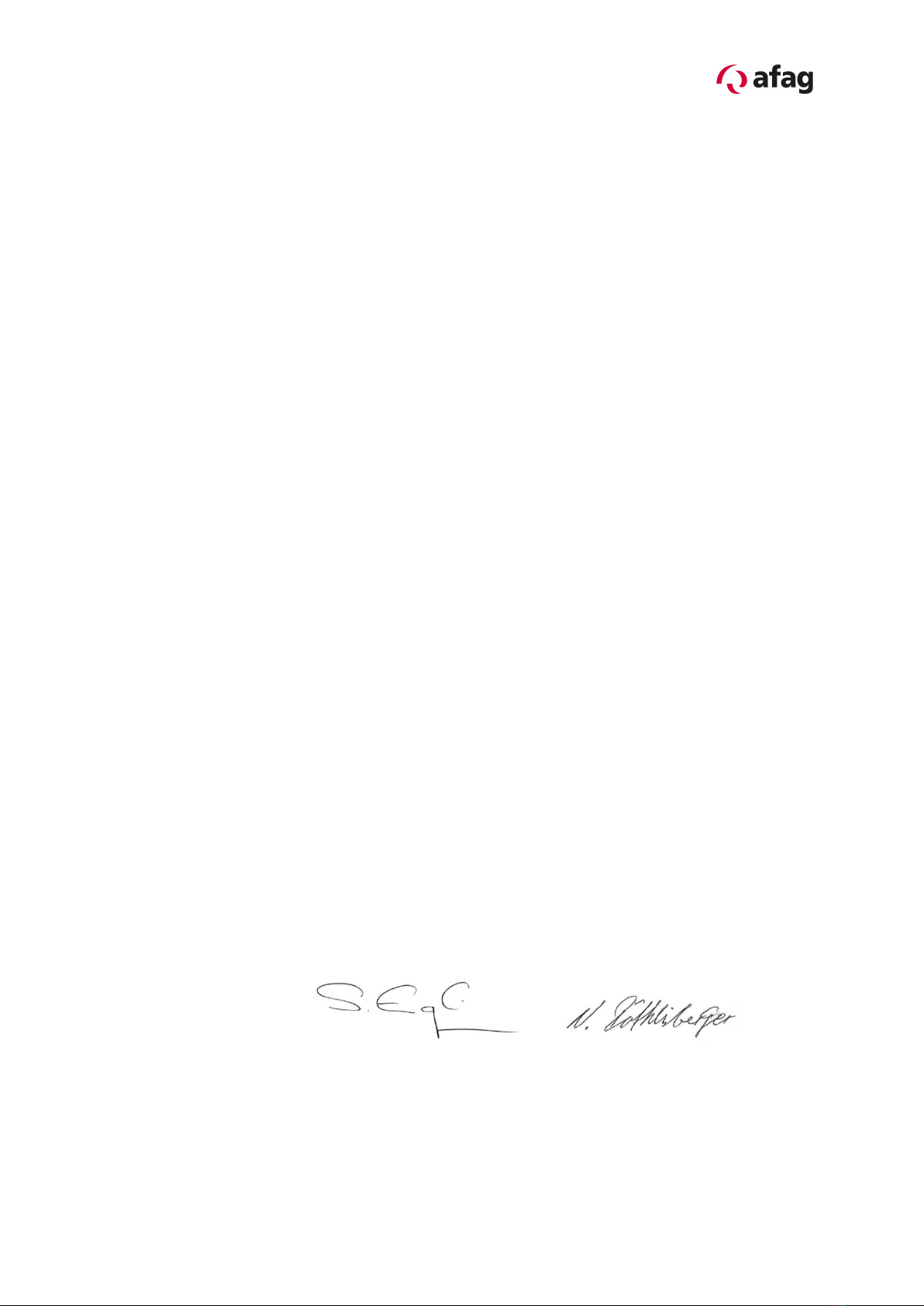

3.1.4 Scope of supply ........................................................................................... 13

3.1.5 Guarantee .................................................................................................... 14

3.1.6 Areas of application ...................................................................................... 14

3.1.7 Dimensions drawing UG 20 ......................................................................... 15

3.1.8 Technical data of the UG 20 ........................................................................ 16

3.1.9 Preferred combinations UG 20 ..................................................................... 17

3.2.0 Module stresses UG 20 ................................................................................ 18

3.2.1 Dimensions drawing UG 25 ......................................................................... 20

3.2.2 Technical data of the UG 25 ........................................................................ 21

3.2.3 Preferred combinations UG 25 ..................................................................... 22

3.2.4 Module stresses UG 25 ................................................................................ 23

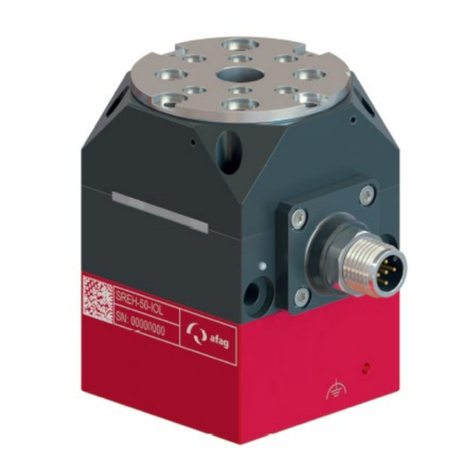

3.2.5 Pneumatic connection for the UG-Universal gripper .................................... 25

3.2.6 Preparation for Commissioning .................................................................... 26

3.2.7 Fitting the proximity switch in the module grooves ....................................... 27

3.2.8 Example of application of sensor technology combined with specially formed

grip fingers (depending on application): ................................................................ 28