4 – 48 Assembly instructions EN DG 16-W Edition 09/2020 Rev. 1.0

5Structure and description ................................................................................... 24

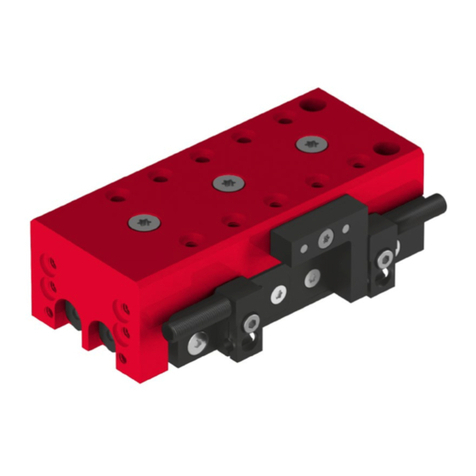

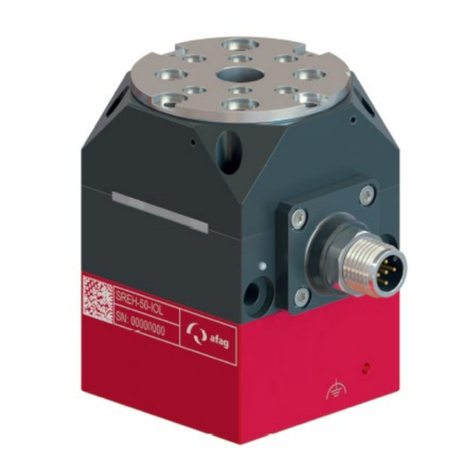

5.1 Structure of the rotary grippers................................................................... 24

5.2 Product description..................................................................................... 24

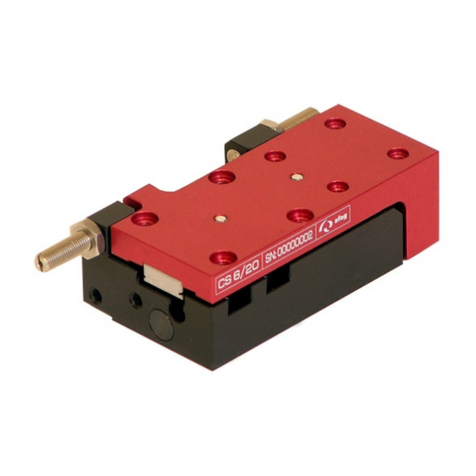

5.3 Accessories ................................................................................................ 25

5.3.1 End stop and attachment kit - DG 16-W .............................................. 25

5.3.2 Sensor system - DG 16-W ................................................................... 26

5.3.3 Connections - DG 16-W ....................................................................... 26

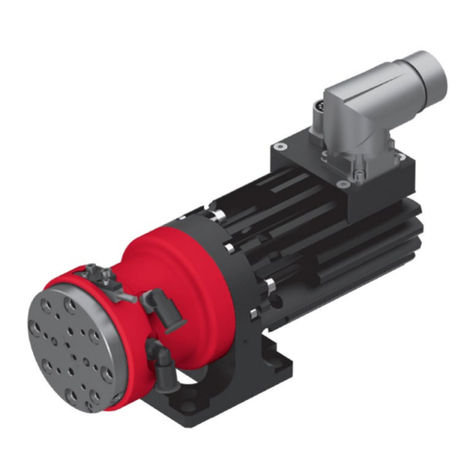

5.4 Field of application and assembly options.................................................. 27

5.4.1 Assembly example DG 16-W ............................................................... 27

6Installation, assembly and setting ..................................................................... 28

6.1 Safety Instructions for installation & assembly ........................................... 28

6.2 Preparation - Manufacture of the gripper fingers ....................................... 29

6.3 Installation and assembly ........................................................................... 29

6.3.1 Assembly and attachment.................................................................... 30

6.3.2 Tightening torques for screws .............................................................. 30

6.3.3 Connection to the pneumatic system ................................................... 31

6.3.4 Mounting of the 90° fixed stop (option) ................................................ 32

6.3.5 Assembly of the sensors ...................................................................... 33

6.4 Settings....................................................................................................... 34

6.4.1 Safety instructions for adjustment work ............................................... 34

6.4.2 Adjustment of the rotary gripper modules DG 16-W ............................ 35

7Commissioning .................................................................................................... 36

7.1 Safety instructions for commissioning ........................................................ 36

7.2 Commissioning of the rotary grippers......................................................... 36

8Fault elimination................................................................................................... 37

8.1 General notes ............................................................................................. 37

8.2 Safety instructions for troubleshooting ....................................................... 37

8.3 Table Fault causes and remedy ................................................................. 37

8.3.1 Troubleshooting table........................................................................... 37

8.3.2 Sensor fault .......................................................................................... 38

9Maintenance and Repair...................................................................................... 39

9.1 General notes ............................................................................................. 39

9.2 Safety instructions for maintenance and repair.......................................... 39

9.3 Maintenance activities and maintenance intervals..................................... 40

9.3.1 Overview of the maintenance points .................................................... 40

9.3.2 Compressed air specifications ............................................................. 41

9.3.3 Further maintenance ............................................................................ 41

9.4 Spare parts and repair work ....................................................................... 42

10 Decommissioning, disassembly, disposal........................................................ 43

10.1 Safety instructions for decommissioning, dismantling and disposal .......... 43

10.2 Decommissioning ....................................................................................... 43